Home » Forged Steel Fittings » Alloy Steel A182 Socket Weld Tee Dimensions

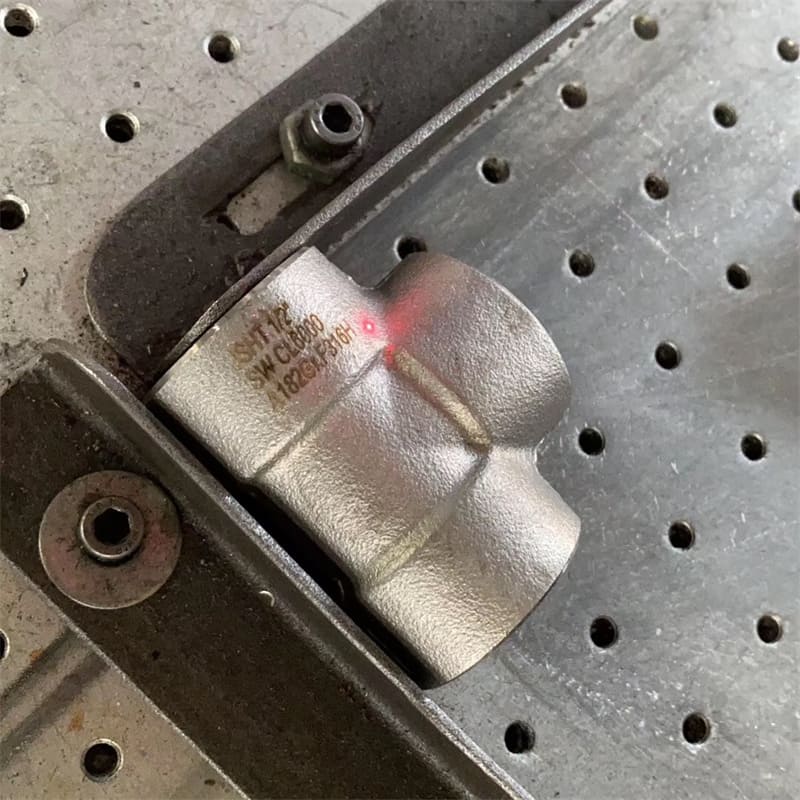

Alloy Steel A182 Socket Weld Tee Dimensions

Socket welded tee are generally suitable for pipes with a nominal diameter of NPS 2 or less.

Contact US

Get Price

Share:

Content

Production Description

SW Equal Tee

The diameter of equal tee branch pipe is the same as that of pipeline, so we also call it straight tee.

SW Reducing Tee

Alloy Steel A182 Socket Weld Tee Dimensions has different end diameters. It connects the three pipes together at one joint and reduces the fluid flow to the receiving end.

Product features

- Socket Weld Tee Fittings have socket at the edges where there pipe could be inserted and welded for optimum grip.

- In contrast to butt weld fittings, Socket Weld Fittings are mainly used for small Pipe Diameters .

- Socket welded tee are generally suitable for pipes with a nominal diameter of NPS 2 or less.

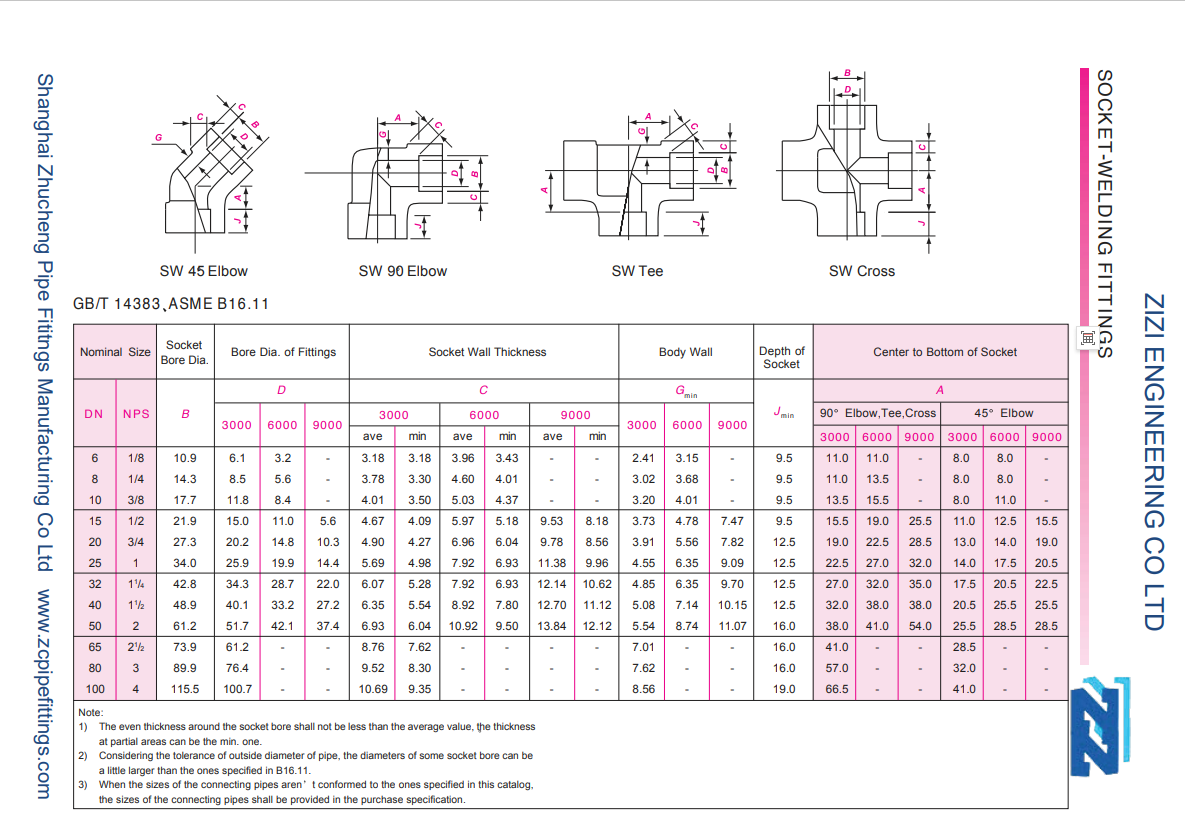

Product Specification

| Shape | Equal and Reducing |

| Size Range | 1/8″- 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000LBS, 6000Lbs, 9000lbs. |

| Standard | ASME B16.11, BS3799 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temperature Steel | ASTM A350 LF2 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 22 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304 / 304L / 304H, 316 / 316L, 321, 310S, 317, 347, 904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Socket Weld Tee Dimensions

Inquiry

More Socket Weld Fittings