ASTM A182 Stainless Steel Slip On Flange Dimension

A flange can be defined as a method that helps in connecting pipes, valves, etc., to form a full piping system. There are seven flange classes ranging: #150, #300,#400, #600, #900, #1500 #2500.

ASTM A182 Forged Stainless Steel Flange

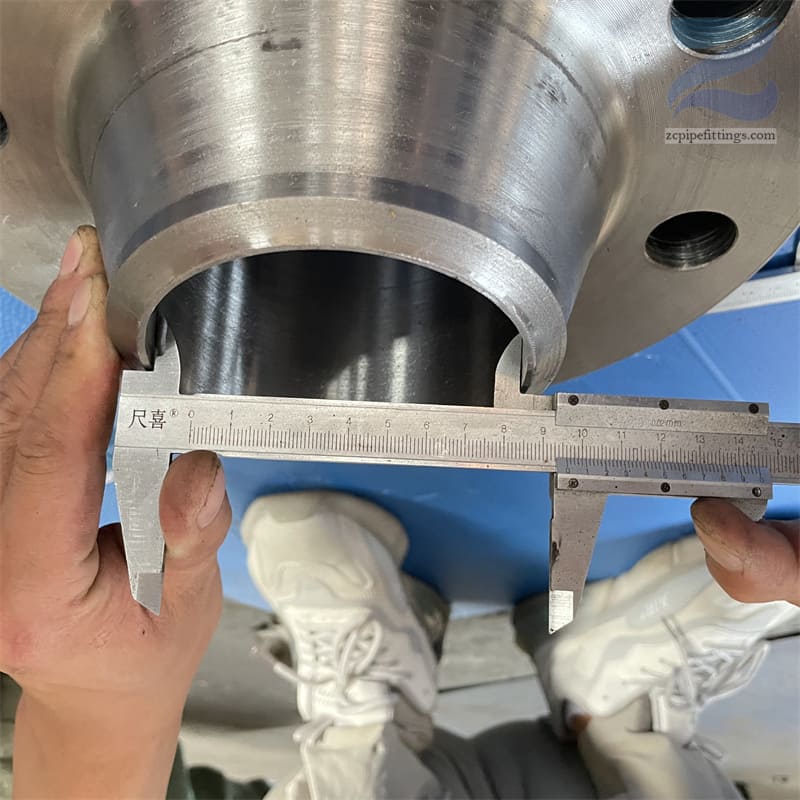

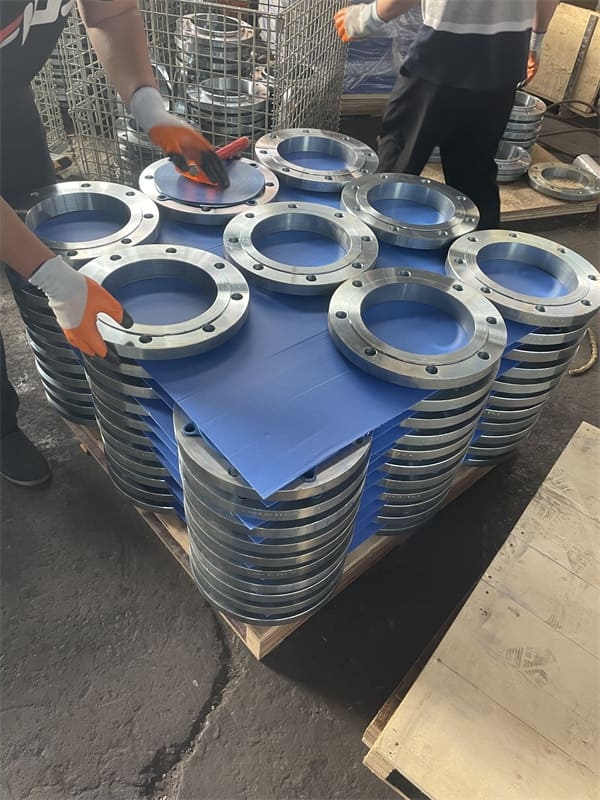

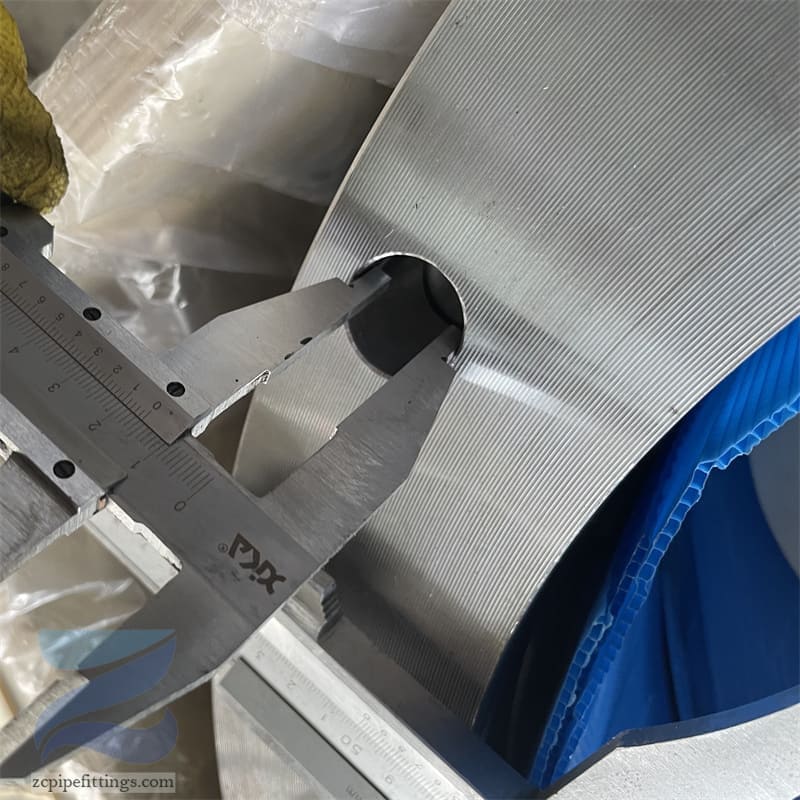

ASTM A182 is the standard of slip on flange in stainless steel, alloy steel. We will inspecte the demension, tolerance, surface and packing when delivery.

We are the manufacturer of steel flange and pipe fittings. Slip on flange, also called SO flange, is the common type of steel flange. The specification of ASTM A182 is the standard of forged fittings, stainless steel, rolled alloy, forged alloy, pipe flanges and pipe fittings.

These Forged Stainless Steel Flange and Pipe Fittings are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

The specification of ASTM A182 is the standard of forged fittings, stainless steel, rolled alloy, forged alloy, pipe flanges and pipe fittings as well as high-temperature service. Later then forgings and hot working, it would be cooled down to a certain temperature before heat treatment.

The common material grade of stainless steel ASTM A182 contains F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437.

Slip on flange can be made by forging, steel cutting, casting and etc. Among these manufacturing types, the forging type gains the best quality and also the most common use.

Slip on flange, also called SO flange. It’s a kind of flange slides over the pipe with internal design is slightly larger than the pipe. Since the inner diameter of the flange is slightly larger than the outer diameter of the pipe, the SO flange can be directly connected to equipment or pipe by fillet weld at the top and bottom of the flange. It is used to insert the pipe into the inner hole of the flange.

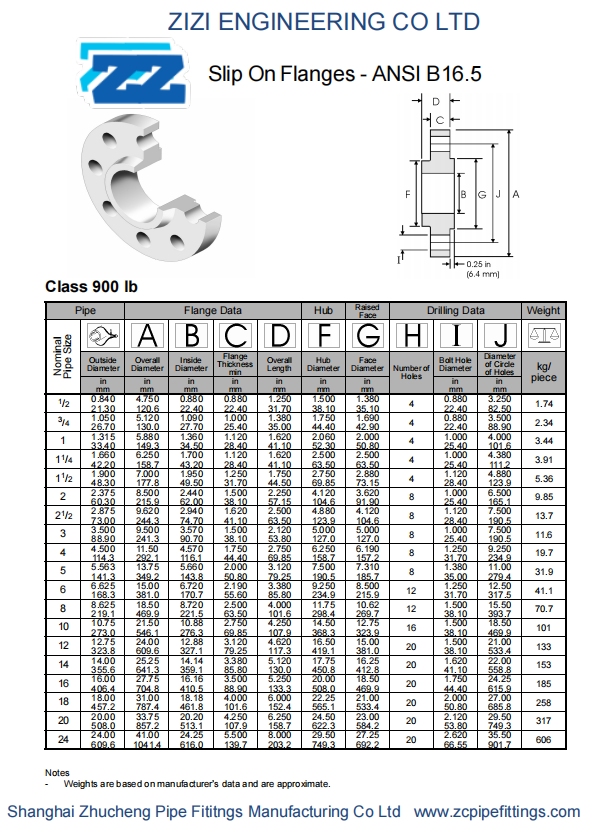

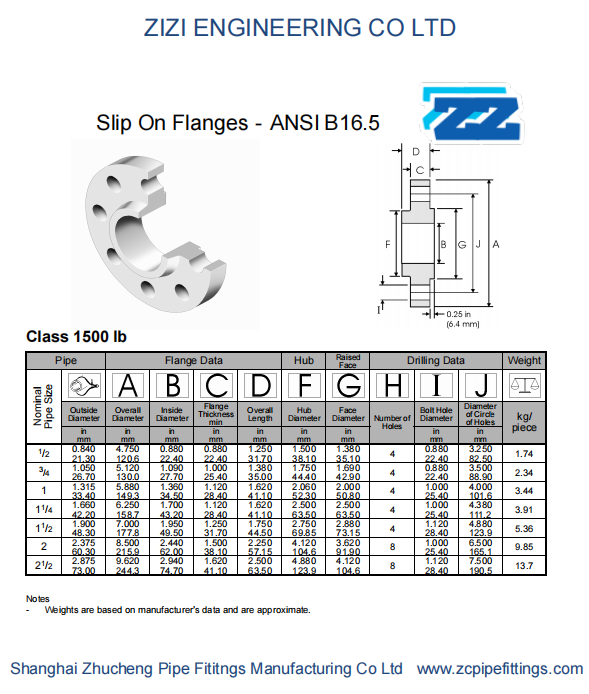

Slip On Flange Dimension

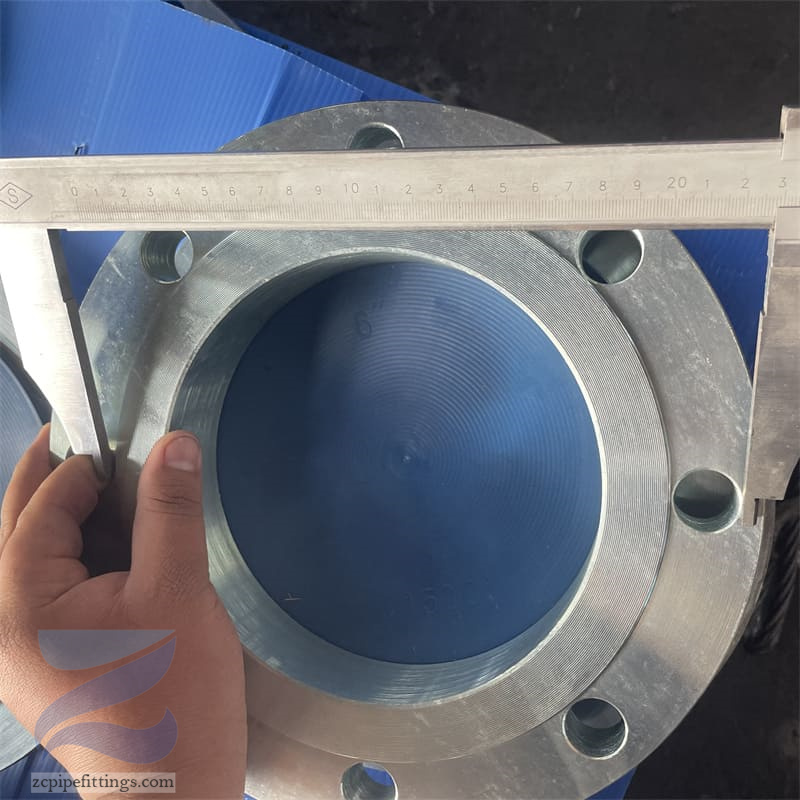

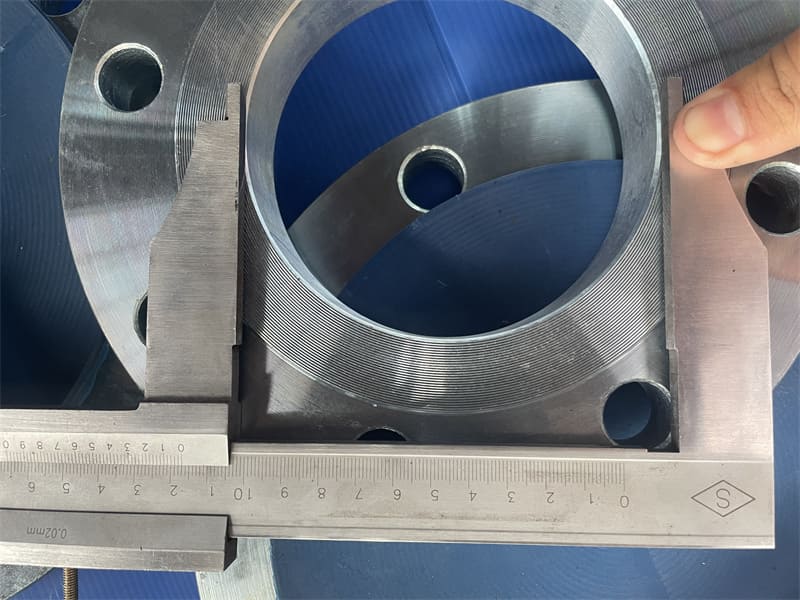

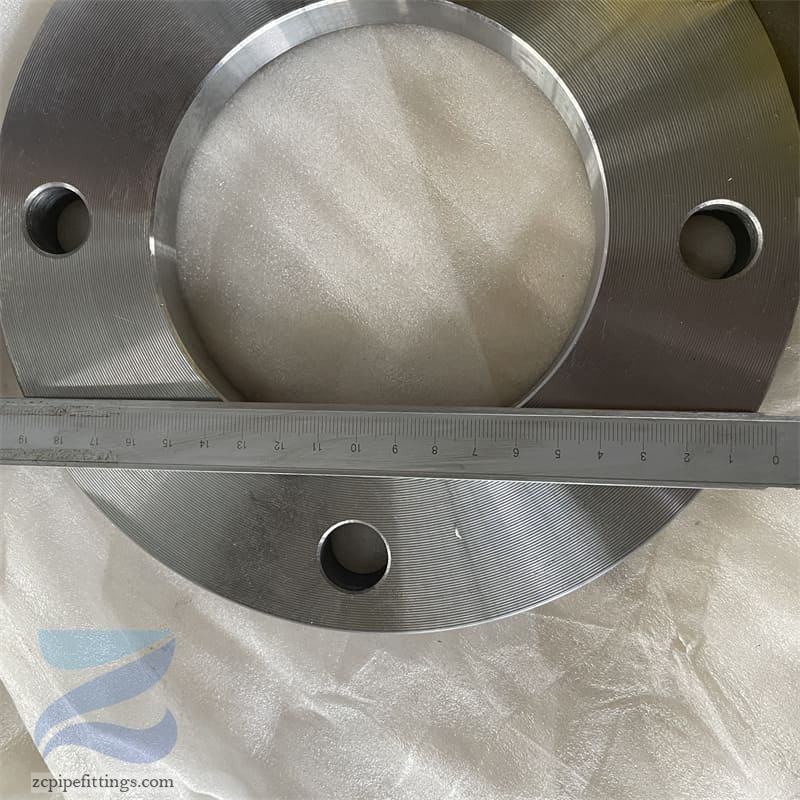

The distance from the center of the flange hole, as the name suggests, refers to the distance between the centers of the two opposite holes on the flange.

Flange center distance is the distance from the center of the flange bolt hole to the center of the diagonal bolt hole. When measuring, take the distance from the inside of one end of the bolt hole (as shown in the figure above) to the outside of the diagonal bolt hole as the center moment of the flange. To ensure the correct installation of telescopic energy saving, the bolt diameter and number of holes should also be measured.

| Forged Steel Flanges Specification | |

| Shape | Weld Neck Flange ( WN),Slip-on Flange (SO), Threaded Flange (THD),Socket Weld Flange (SW),Blind Flange (BL),Lap Joint Flange (LAPJ),Plate flange (PL) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Slip On Flange Specification and Drawing

A flange can be defined as a method that helps in connecting pipes, valves, etc., to form a full piping system. There are seven flange classes ranging: #150, #300,#400, #600, #900, #1500 #2500. Governed by B 16.5 standards, the ASME B16. 5 Class 900 Flange provides a pressure capacity of 600Lb, Class 1500 Flange provides a pressure capacity of 1500Lb