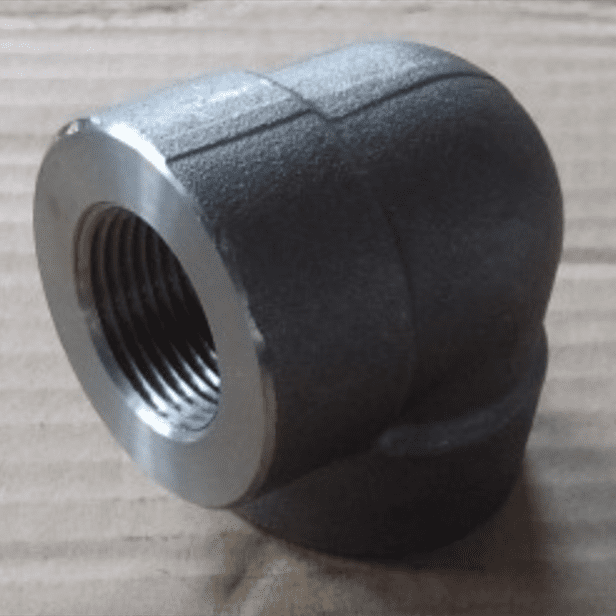

ASTM A182F304L 3IN 3000PSI 90degree Elbow NPT

Forged threaded elbows are very common in chemical, oil refining, petrochemical and other industries, and are also used in some other industries.

ASTM A182F304L 3IN 3000PSI 90degree Elbow NPT is actually a fitting that is being installed in between the two lengths of tube or a pipe to allow in changing the direction of a flow.The threaded reducing elbow made of stainless steel allows you to transition pipe size and divert direction of flow with only single fitting as they can be used for both purposes stated above.The 90° threaded reducing elbow eliminates the need of installing one more pipe fitting and reduces the installation respectively the chance of failure by more than one-third.Also, the gradual reduction in diameter throughout the arc of the stainless threaded reducing elbow provides much lower resistance to flow and reduces the effect of stream turbulence and potential internal erosion. These features prevent sizeable pressure drops in the line. Available in different material grades and in BSP or NPT thread.

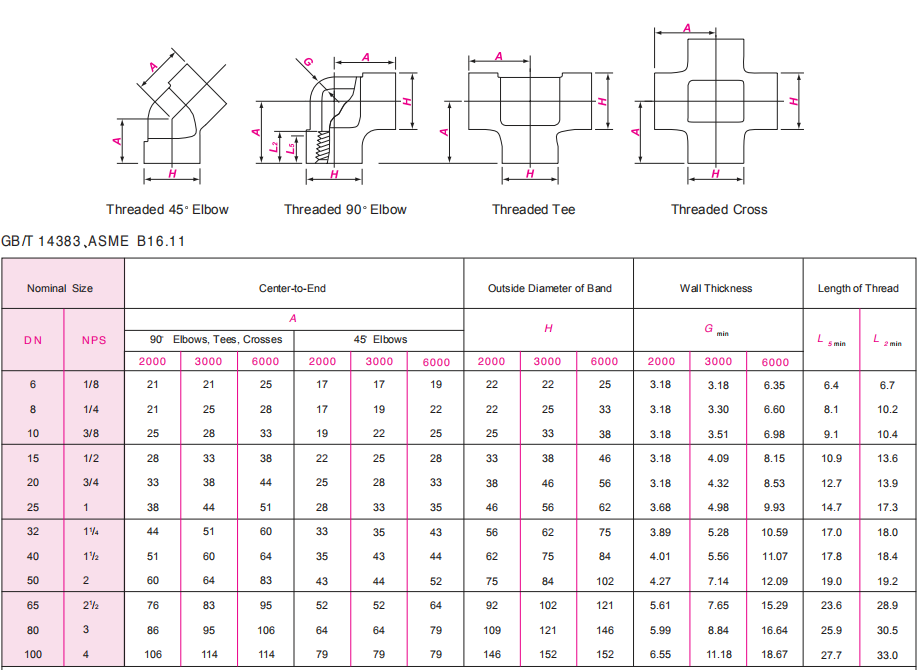

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

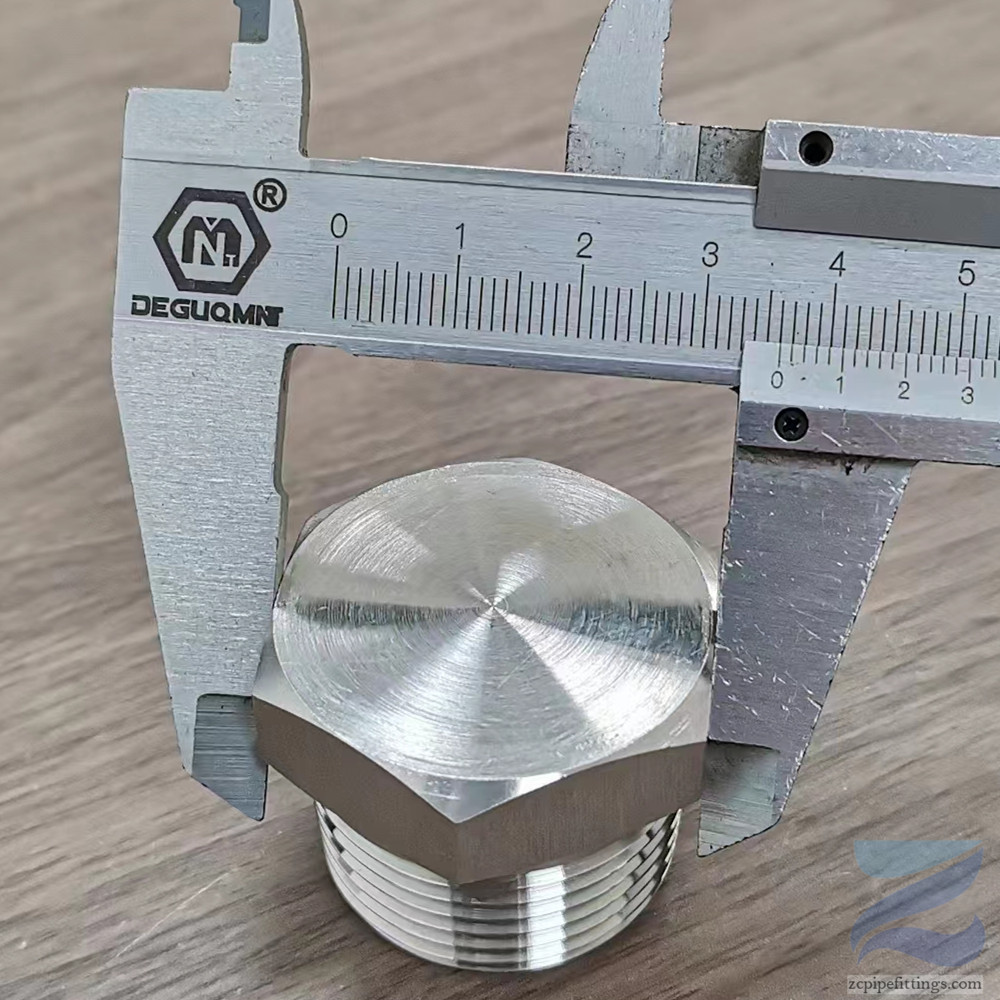

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

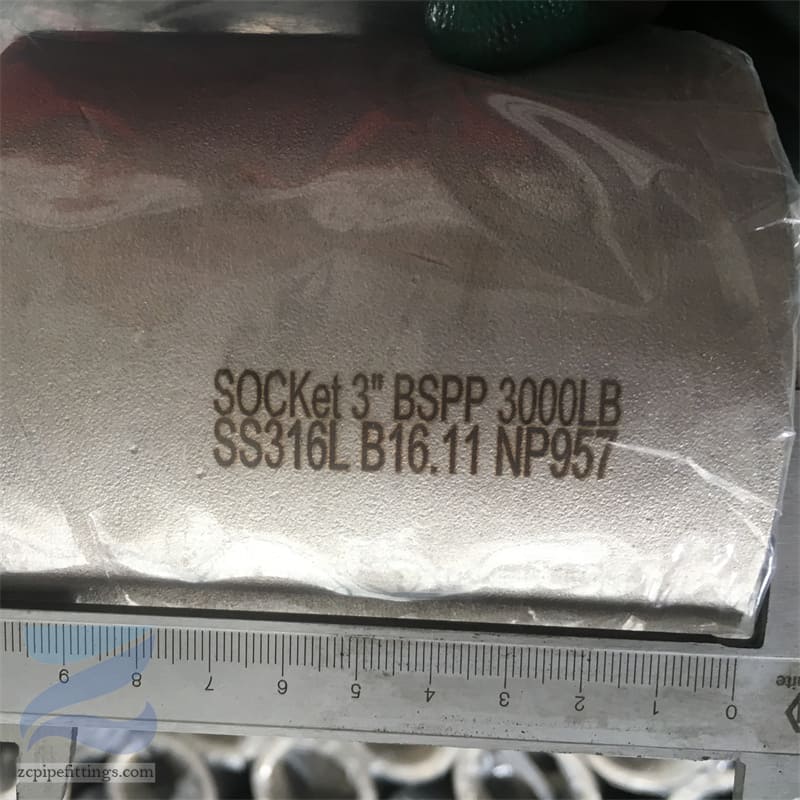

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Seamless Elbow Manufacturing Process (Heat Bending & Cold Bending)

One of the most common methods for manufacturing elbows is using hot mandrel bending from straight steel pipes. After heating the steel pipe at a elevated temperature, the pipe is pushed, expanded, bended by the inner tools of mandrel step by step. Applying hot mandrel bending can manufacture a wide size range seamless elbow. The characteristics of mandrel bending are strongely depend on the intergrated shape and dimensions of the mandrel. The using advantages of hot bending elbows include smaller thickness deviation and stronger bending radius than other bending methond type. Meanwhile, using bending instead of prefabricated bends substantially reduces the number of welds needed. This reduces the amount of work required and increases the quality and usability of pipes. However, cold bending is the process to bent the straight steel pipe at normal temperatures in a bending machine. Cold bending is suitable for pipes with an outer diameter of 17.0 to 219.1 mm, and wall thickness 2.0 to 28.0 mm. The recommended bending radius is 2.5 x Do. Normally at a bending radius of 40D. By using cold bending, we can get small radius elbows, but we need to pack the internals with sand to prevent wrinkling. Cold bending is a quick and inexpensive bending method. It is a competitive option for making pipelines and machine parts.

Advantages:

- Easy to install.

- Firm and durable.

- Corrosion resistance.