Home » Forged Steel Fittings » ASTM A105N Carbon Steel 45 Degree Socket Weld Elbow

Content

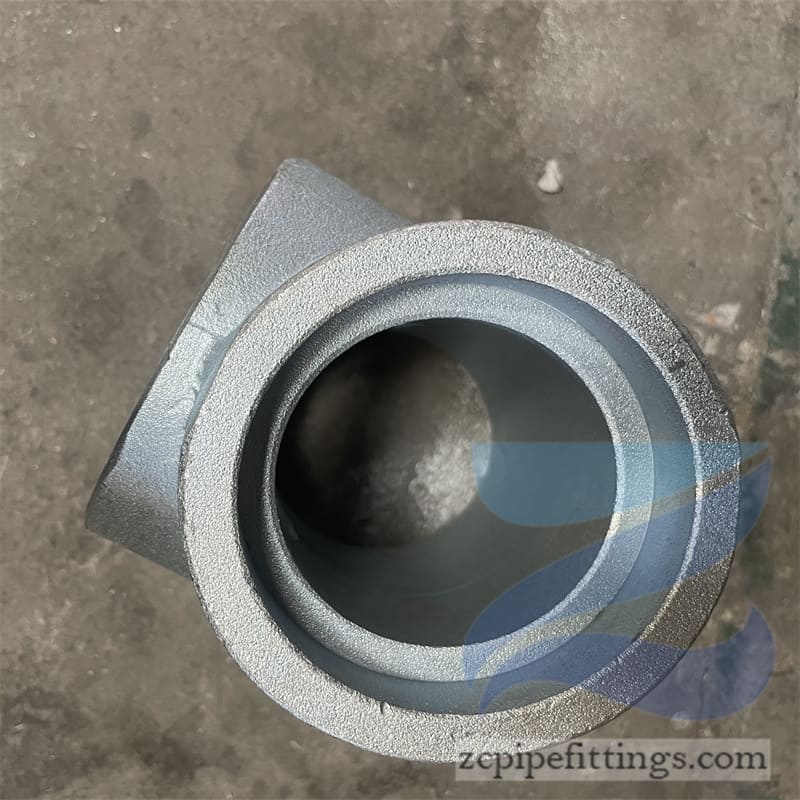

What is a Forged Socket Weld 45 Deg Elbow

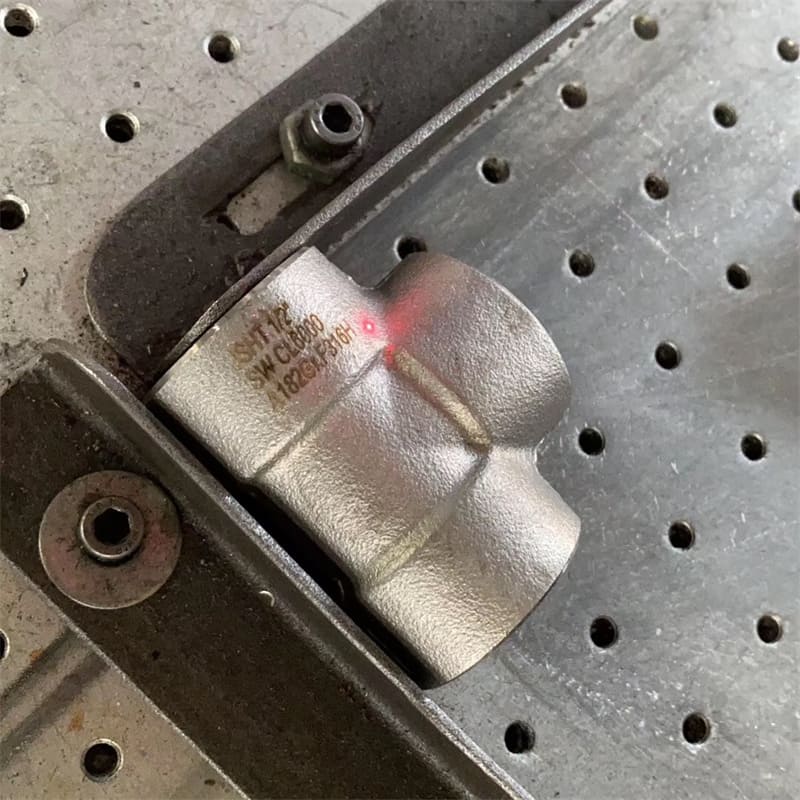

The Forged Socket Weld 45 Deg Elbow are resistance to corrosion/pitting/oxidation/stress corrosion cracking and crevice corrosion. It is having the high tensile strength and good dimensional accuracy to offer. Additionally, it withstands heavy loads and also withstands in the high-temperature atmosphere.

Specification of The Forged Socket Weld 45 Deg Elbow

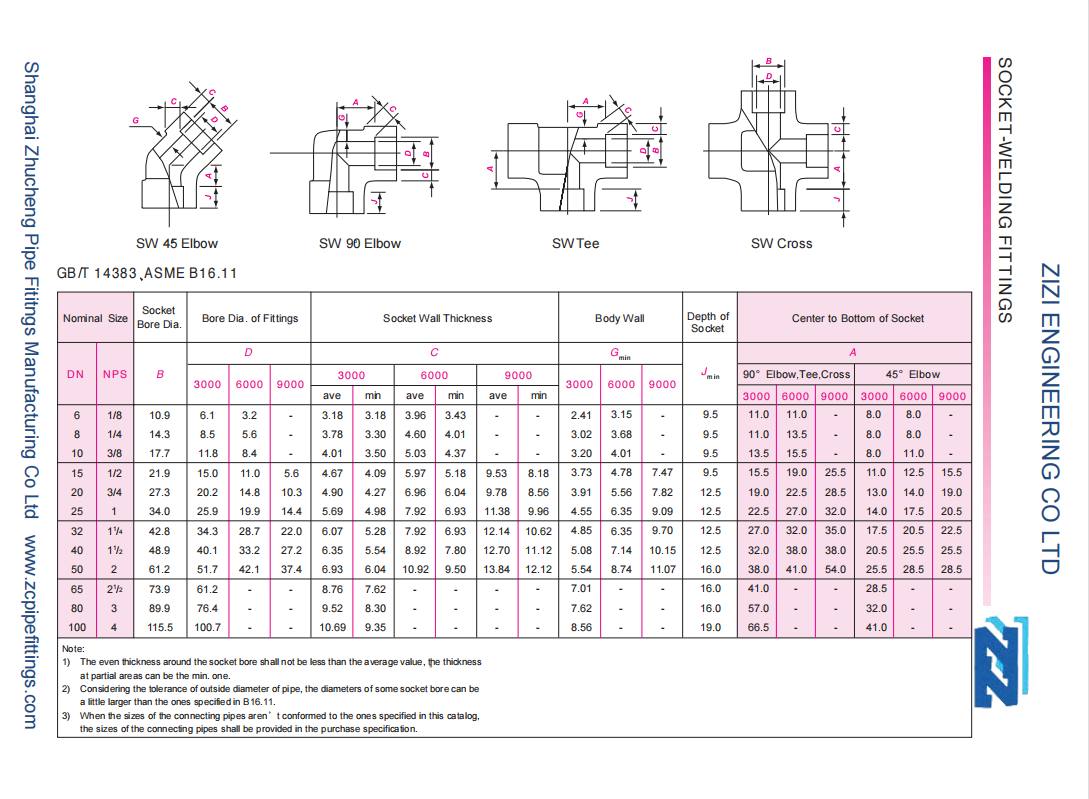

| Type | 90 Degree and 45 Degree |

| Shape | Straight and Reducing |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | GB/T 14383, ASME B16.11, BS3799 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Advantages of Socket Weld Pipe Fittings

The socket weld pipe fittings can be used in place of threaded fittings,so the risk of leakage is much smaller.

Socket weld pipe need not be beveled for weld preparation.

The weld metal can not penetrate into the bore of the pipe.

Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

Inquiry

More Socket Weld Fittings