Butt Weld A403WP304 90Degree Long Redius Elbow

Butt weld fittings would also be referred to as welded pipe fittings. When these would be used in stainless steel and carbon steel, they would be able to offer certain advantages as compared to socket weld and threaded fittings. Whereas socket weld would only be available up to a specific size, you would find butt weld fittings to be available in sizes starting 1/2 inch to 72 inch.

Butt weld fittings is one of the most popular connection type in pipeline systems. It always been required in large quantities in different industries, and especially for the large diameter pipelines.

What is Butt Weld Fittings

Butt weld is to connect pipes or fittings ends by welding. It’s a weldable steel pipe fitting that would allow to branch off, allow for change of direction of flow, attach auxiliary equipment, or reduce the size of the pipe.In the case of forged steel butt weld fittings, you would find them to be manufactured according to ANSI/ASME B16.9.

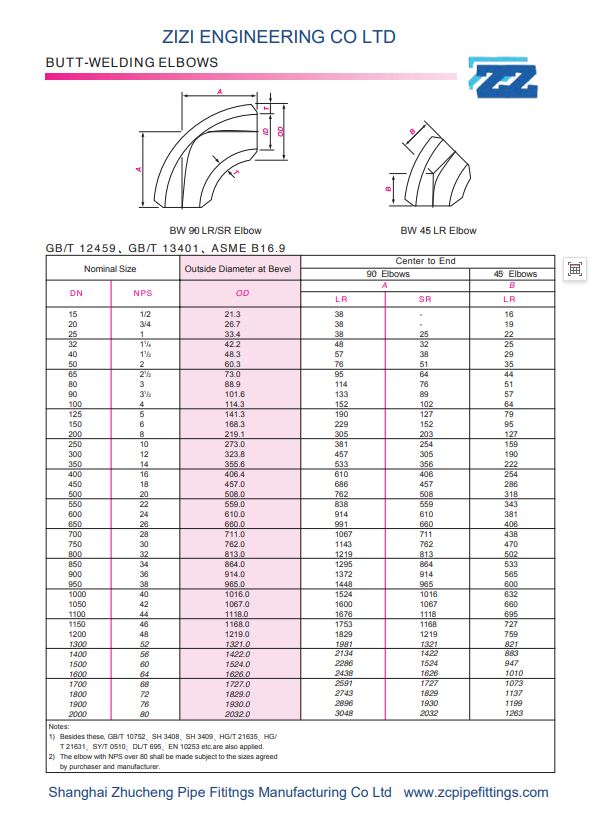

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Like general category of pipe fittings, Butt weld pipe fittings includes:

Butt weld Elbow in 45 degree or 90 degree

Butt weld Tee and Reducing Tee, Reducer, Cap, Cross

Stainless steel butt weld fittings usually in thin thickness

Just like you would find normal pipe to be sold from Schedule 10 to Schedule 160, you would find the case to be same for butt weld fitting as well. In stainless steel, butt weld fittings have been found to be more common. This would be thanks to the cost advantage that it has to offer. Schedule 10 fittings would also be more common in stainless steel fittings.

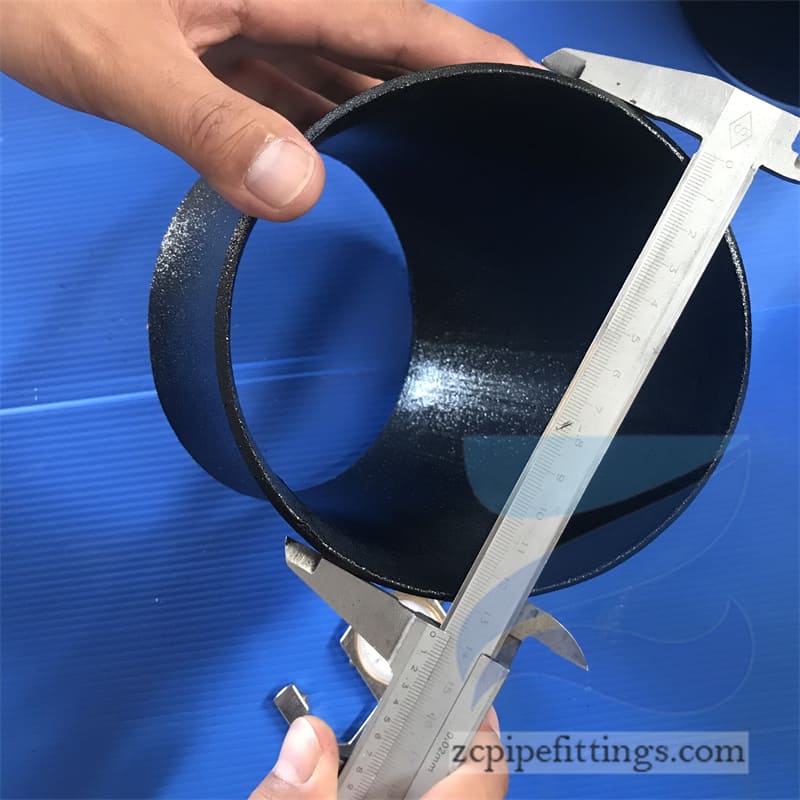

How a butt weld fitting is made

This kind of pipe fitting would be made by a process known as hot forming. This would include bending the pipe and then forming it in to a shape. The starting material of this fitting would be a pipe that would first be cut in to length. This would then be heated and molded in to specific shapes with the help pf dies. In addition, heat treatment would also be done in order to get the desired mechanical properties and removed residual stresses.

Benefits of butt weld fittings

• The welded connection would help to get more robust connection

• Continuous structure of metal would add to the strength of the piping system

• When butt weld fittings would be matched with the appropriate pipe schedules, they would help to offer a seamless flow inside the pipe

• It provides the option of various turn radius by using Long Radius, Short Radius, or 3R elbows

• Found to be cost effective compared to the socket weld or threaded counterparts

• These fittings would be available in Schedule 10, thus allowing for a thinner wall option

• These fittings have been found to be more common in the configuration of Schedule 10 and Schedule 40.

Functions of butt weld pipe fittings

Butt weld pipe fittings in the case of stainless steel and carbon steel would be the joining components. Thanks to this, it would be possible to assemble pipes, valves, and equipment on to the piping system. In addition to complimenting pipe flanges in any piping system, butt weld fittings would also allow:

• Change of the direction of flow in a piping system

• Join or connect equipment and pipes

• Provide access, branches, and takeoffs for auxiliary equipment.

One common example of this would be to use a butt weld pipe fitting in a pipe that would be reduced by concentric reducer. This would then be welded to a weld neck flange and then connected to an equipment.