Carbon Steel ASTM A234 WPB Concentric Reducer

Concentric reducer in a pipe system, its making process and its difference between a eccentric reducer.

What is a Concentric reducer?

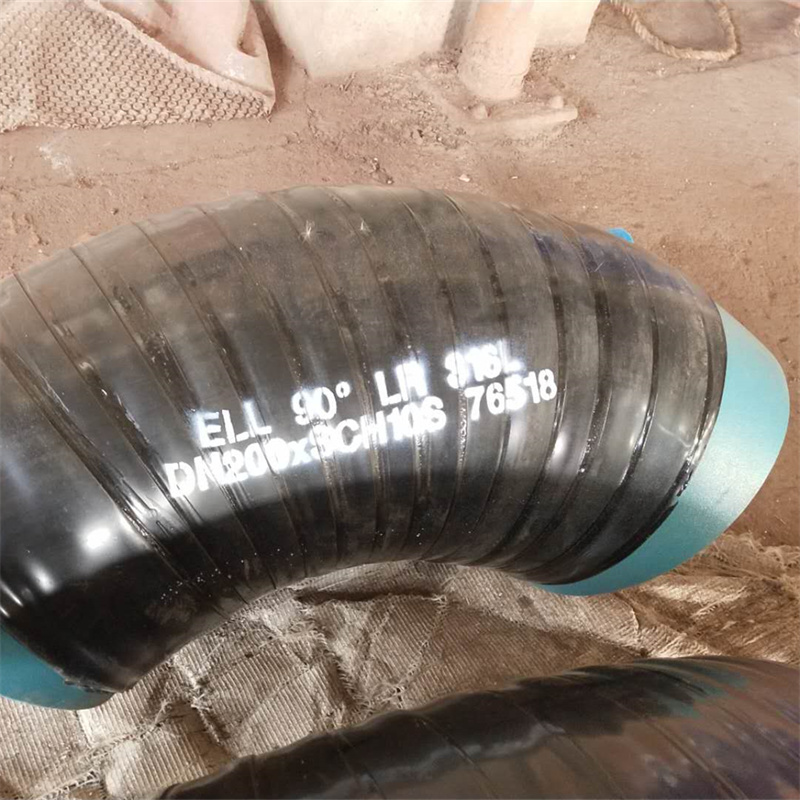

A concentric reducer, which is also known as a tapered expansion joint, is a fitting used to connect two pipes or tubes that have different inside diameters. Both tubes need to share a common centerline or alignment in order to facilitate the flow of fluid or a substance. Reducers can be manufactured using rubber, stainless steel, carbon steel, steel alloy, titanium alloy, copper, nickel, cast iron, brass, or other materials that have met the standards of the pipe industry. It is normally used in joining vertical pipes that need to be anchored for safety reasons. Concentric reducers are common in both the onshore and offshore operation of the oil and gas industry where there is a heavy volume of cargo transfer and vapor recovery.

Concentric Reducer vs Eccentric Reducer Differences

Concentric reducers are widely used while eccentric reducers are applied to maintain the top and bottom pipe level. Eccentric Reducers also avoids trapping of air inside the pipe, and Concentric Reducer removes noise pollution.

Manufacturing Process of Steel Pipe Reducer

There are versatile manufacturing processes for the reducers. These are made of welded pipes with the required filling material. However, EFW and ERW pipes cannot use the reducer. To manufacture forged parts, different kinds of methods are used including cold and hot forming processes. It includes the ‘Outer Die Method.’