Buttwelding Fittings

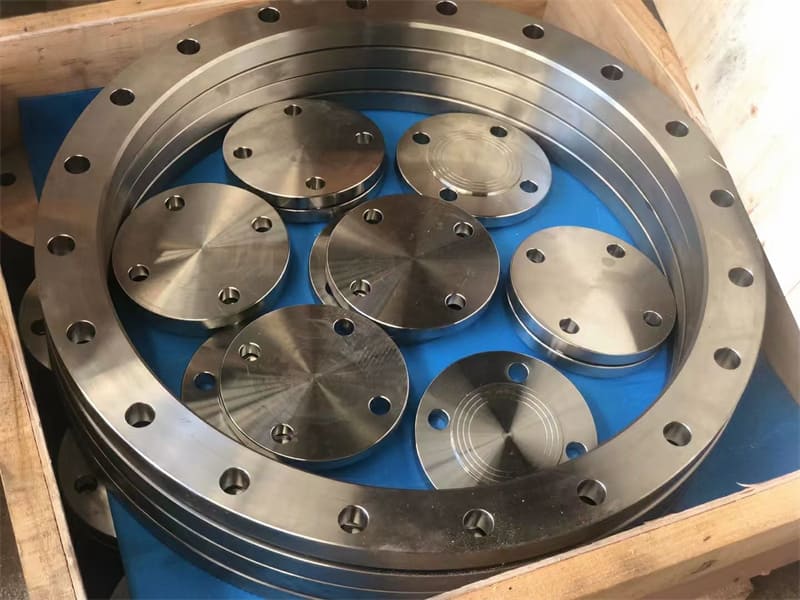

Bakin karfe kayan da kanta na da kyawawan juriya. Bakin karfe zamantakewa akan flanges masu farrafai na iya yin tsayayya da lalata a cikin yanayin wurare daban-daban, kamar bututun masana'antu da kuma bututun hawa da ke tattare da wasu acid da alkali.

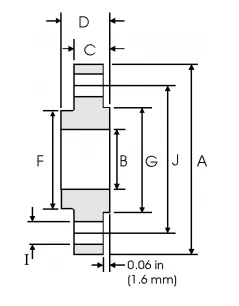

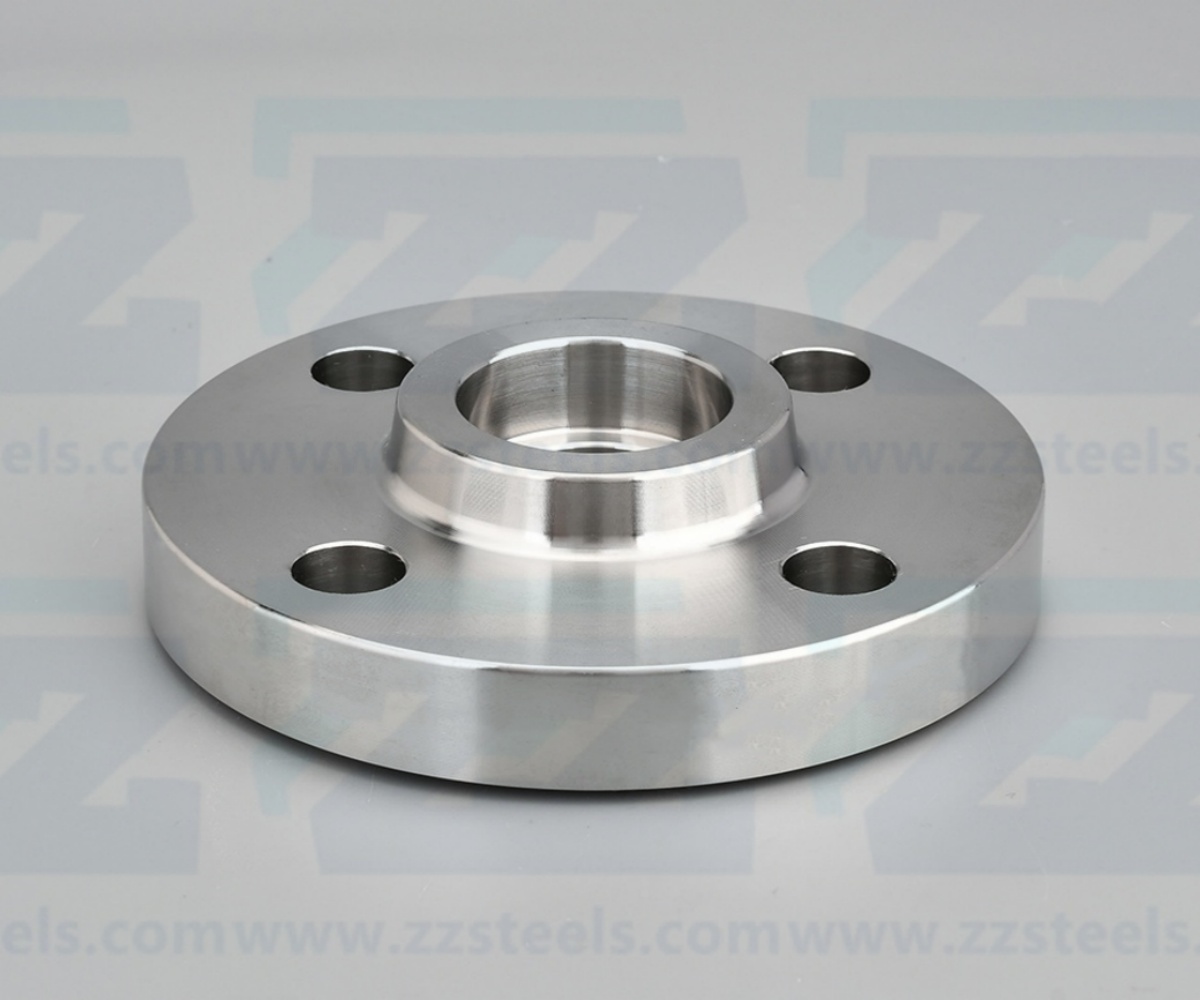

Slip a kan mai fashin, yana kuma kiranta da haka flani. Wata irin slides na flange ne akan bututun da ƙirar ciki ya ɗan fi girma bututu. Tun da diamita na ciki na flanger na ciki yana da ɗan girma fiye da na m diamita na bututu, don haka flanget zai iya haɗa kai tsaye zuwa kayan aiki ko bututu ta fillet a saman da kasan flange. Ana amfani dashi don saka bututun a cikin rami na ciki na flangen.

A182 f30 flange yana da juriya na lalata jiki, juriya da zafi da kuma kayan aikin injin, kuma ya dace da sarrafa jeri, magani na gida da sauran filayen.