Lap hadin gwiwa Stub End Bw Fittings

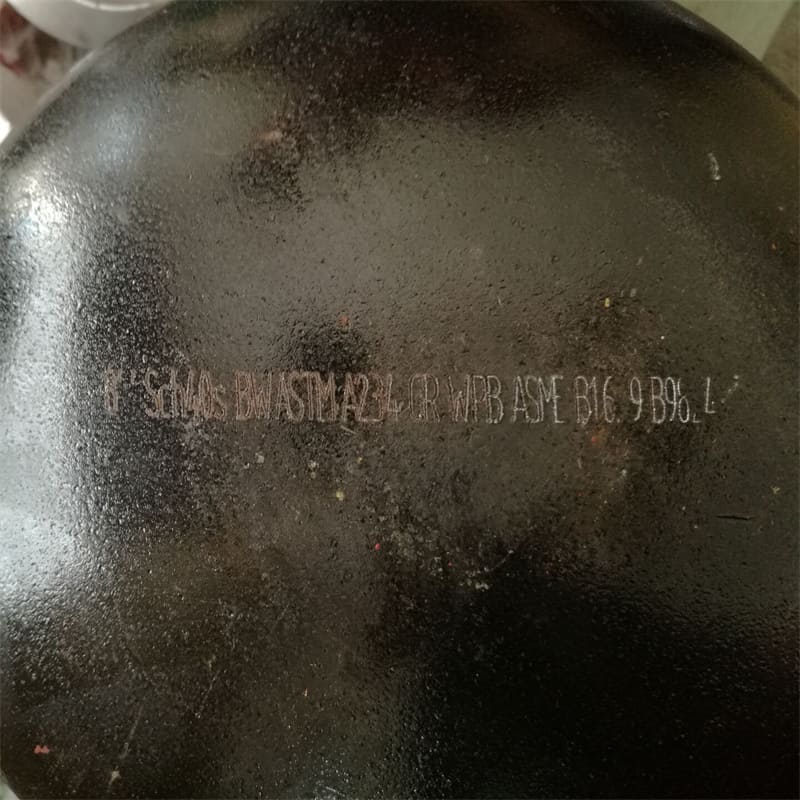

Asme B16.9 Gicciye bututun bututu ne da aka yi amfani da su don haɗa bututu huɗu tare, kuma ana samun haɗin haɗin ta hanyar waldi. Yana taka rawa a cikin rarrabuwa ko kuma ya shafi tsarin bututun mai kuma muhimmiyar mai haɗi ne a cikin shimfidar bututun bututun.

45 de deg engle na iya canza gefen ruwaye ko gas a cikin digiri 45. Altere yana da Elbows 90 Digiri na Elbows na iya zama daidai Tee da Rage Tee don gamsar da bukatun daban-daban.

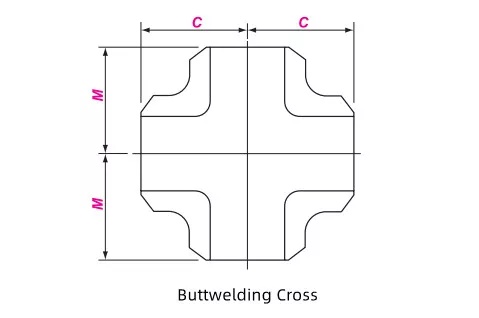

A Butt-Weld giciye yawanci yana da musaya huɗu, da girma da kuma takamaiman abubuwan wannan musayar. An tsara tashar cikin ciki don tabbatar da cewa ruwan zai iya gudana cikin jiki a cikin giciye kuma rage asara. Misali, a wasu tsarin bututun masana'antu, ana iya aiwatar da musayar gicciye na bututun mai za'a iya aiwatar da su daidai gwargwadon ayyukan da bututun, kuma za a kula da musayar ayyukan da ke cikin bututun.