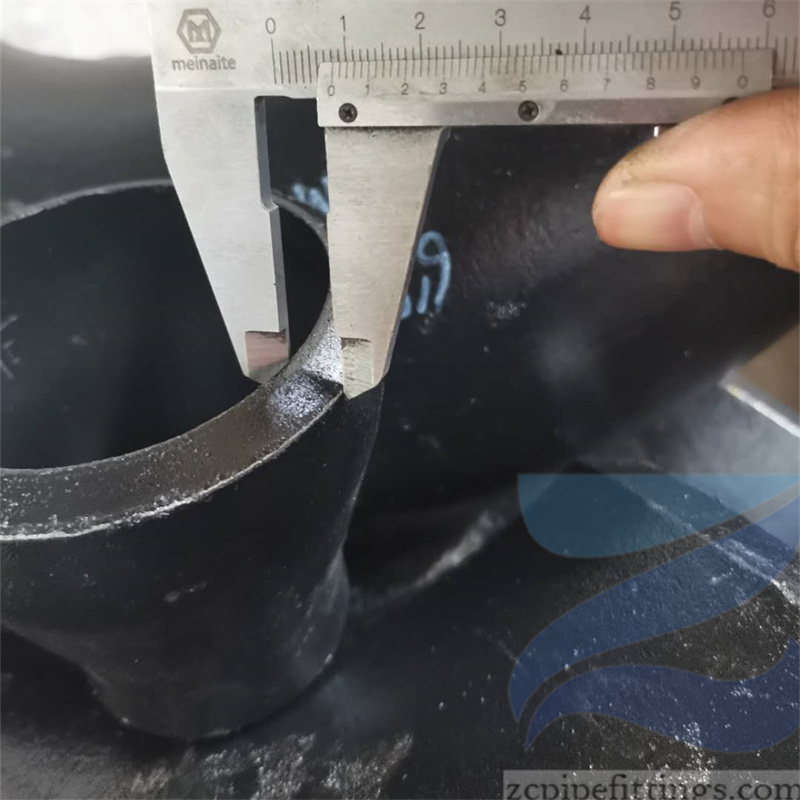

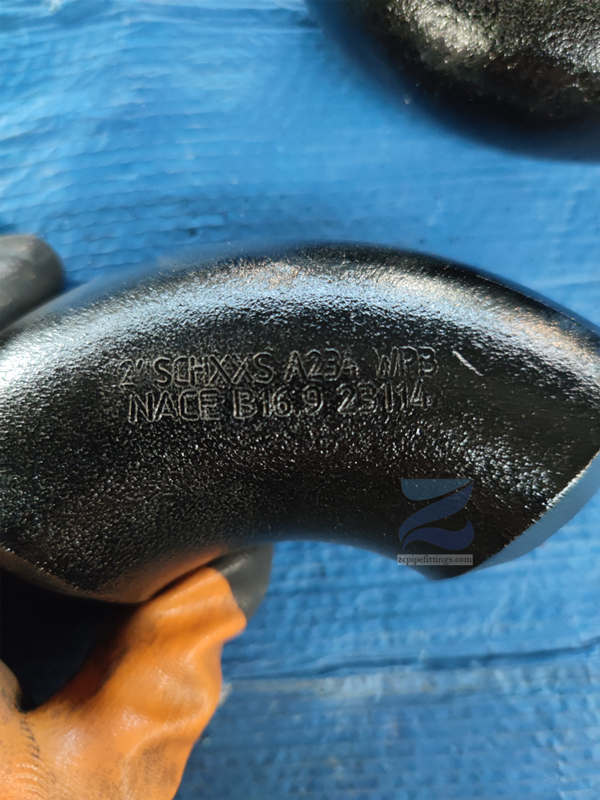

Gịnị Bụ Na Na Na?https: \ / \ / www.zzpiefitings.comYiddishASTM A234 WPB carbon brew bw

Bengali

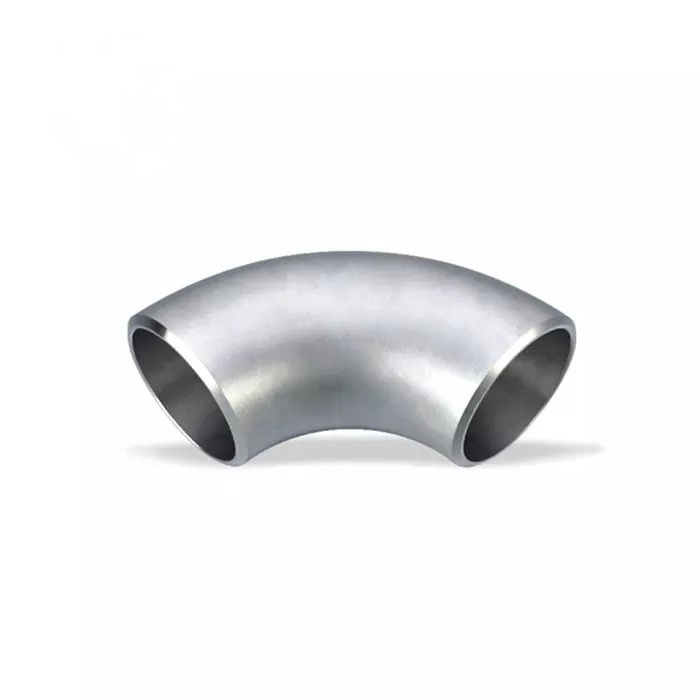

Carbon lut Beln Belping 90 ikio bụ njikọta nke ejiri rụọ ọrụ maka iji sistemụ piping. Ọrụ ya bụ iji mepụta ogo 90 na ọkpọkọ ka mmiri ahụ nwee ike iru n'okporo ụzọ a kara aka. A na-ejikarị eriri nchara a. Ọ dị mma maka gburugburu ụlọ ọrụ dị iche iche n'ihi ike ya dị mma na nguzogide corrosion. Igwe eji eme ka celbon elu 90 na-arụ ọrụ dị mkpa na sistemụ ụlọ ọrụ na-arụ ọrụ, dịka ọ dị na ụlọ ọrụ dị ka petrochemicals, ike na owuwu.

1 \ / 2 "- 80" \ / DN15 - 2000

| »Home» | Gịnị bụ mkpịsị ugodi ya na mkpa nkọwa ya. |

| Bw na-eme ka i nọdụrụ ala | ASI \ / ASME B16.9, MSS SP 43, Jis B2311 \ / 2312 \ / 2313, en10253 |

| Eynonia | Asme \ / Ansi B16.9 igwe anaghị agba nchara A403 Bold Tee |

| Alloy steel coot | Arịre China: GB \ / T12459, GB \ / T13401, HG \ / 216408 \ / 3409 \ / 3409 |

Igwe anaghị agba nchara a403 Bold 90

| Njikọ: | SCH40 | HMong | Kher | Latin | Sch60 | Maori | Tamil | Ulo | Tajik | Ruseque | Nepali | Aha ha | SCH80 |

| 15 | 1/2 | 0.06 | – | 0.07 | 0.08 | 0.08 | – | 0.11 | 0.11 | – | – | 0.13 | 0.17 |

| 20 | 3/4 | 0.08 | – | 0.09 | 0.11 | 0.11 | – | 0.14 | 0.14 | – | – | 0.19 | 0.24 |

| 25 | 1 | 0.13 | – | 0.14 | 0.16 | 0.16 | – | 1.12 | 1.12 | – | – | 0.28 | 0.36 |

| 32 | 1 1/4 | 0.21 | – | 0.24 | 0.28 | 0.28 | – | 0.24 | 0.24 | – | – | 0.47 | 0.64 |

| 40 | 1 1/2 | 0.28 | – | 0.35 | 0.4 | 0.4 | – | 0.53 | 0.53 | – | – | 0.71 | 0.94 |

| 50 | 2 | 0.47 | – | 0.59 | 0.71 | 0.71 | – | 0.98 | 0.98 | – | – | 1.46 | 1.76 |

| 65 | 2 1/2 | 0.79 | – | 1.32 | 1.42 | 1.42 | – | 1.87 | 1.87 | – | – | 2.45 | 3.35 |

| 80 | 3 | 1.16 | – | 1.95 | 2.22 | 2.22 | – | 3.01 | 3.01 | – | – | 4.2 | 5.45 |

| 90 | 3 1/2 | 1.55 | – | 2.62 | 3.12 | 3.12 | – | 4.28 | 4.28 | – | – | – | – |

| 100 | 4 | 2.02 | – | 3.39 | 4.22 | 4.22 | – | 5.86 | 5.86 | – | 7.44 | 8.81 | 10.8 |

| 125 | 5 | 3.46 | – | – | 7.15 | 7.15 | – | 10.2 | 10.2 | – | 13.2 | 16.1 | 18.9 |

| 150 | 6 | 4.98 | – | – | 11.2 | 11.2 | – | 16.8 | 16.8 | – | 21.4 | 26.7 | 31.3 |

| 200 | 8 | 9.57 | 17.6 | 19.4 | 22.4 | 22.4 | 28 | 34.1 | 34.1 | 40 | 47.7 | 58.6 | 56.9 |

| 250 | 10 | 16.7 | 27.5 | 33.6 | 39.7 | 39.7 | 53.7 | 53.7 | 63.2 | 75.5 | 87.6 | 113 | 102 |

| 300 | 12 | 25.9 | 39.3 | 51.5 | 58.3 | 62.9 | 86 | 76.9 | 104 | 126 | 148 | 188 | 148 |

| 350 | 14 | 34.7 | 62.5 | 74.9 | 74.9 | 87.1 | 117 | 98.9 | 146 | 180 | 207 | 259 | – |

| 400 | 16 | 45.4 | 82 | 98.3 | 98.3 | 130 | 169 | 130 | 215 | 259 | 302 | 385 | – |

| 450 | 18 | 56.2 | 104 | 145 | 125 | 185 | 244 | 165 | 302 | 367 | 431 | 545 | – |

| 500 | 20 | 82.2 | 154 | 204 | 154 | 242 | 326 | 204 | 410 | 502 | 581 | 744 | – |

| 550 | 22 | 143 | 187 | 248 | 187 | – | 426 | 248 | 541 | 654 | 763 | 974 | – |

| 600 | 24 | 170 | 223 | 331 | 223 | 403 | 561 | 295 | 698 | 865 | 1011 | 1277 | – |

| 650 | 26 | 200 | 347 | – | 262 | – | – | 347 | – | – | – | – | – |

| 700 | 28 | 232 | 403 | 478 | 304 | – | – | 403 | – | – | – | – | – |

| 750 | 30 | 267 | 464 | 577 | 349 | – | – | 464 | – | – | – | – | – |

| 800 | 32 | 304 | 528 | 658 | 398 | 722 | – | 528 | – | – | – | – | – |

| 850 | 34 | 343 | 597 | 743 | 449 | 817 | – | 57 | – | – | – | – | – |

| 900 | 36 | 386 | 669 | 834 | 504 | 997 | – | 669 | – | – | – | – | – |

| 950 | 38 | – | – | – | 562 | – | – | 746 | – | – | – | – | – |

| 1000 | 40 | – | – | – | 623 | – | – | 828 | – | – | – | – | – |

| 1050 | 42 | – | – | – | 687 | – | – | 913 | – | – | – | – | – |

| 1100 | 44 | – | – | – | 754 | – | – | 1003 | – | – | – | – | – |

| 1150 | 46 | – | – | – | 825 | – | – | 1096 | – | – | – | – | – |

| 1200 | 48 | – | – | – | 898 | – | – | 1194 | – | – | – | – | – |

| 1300 | 52 | – | – | – | 1107 | – | – | – | – | – | – | – | – |

| 1400 | 56 | – | – | – | 1284 | – | – | – | – | – | – | – | – |

| 1500 | 60 | – | – | – | 1475 | – | – | – | – | – | – | – | – |

| 1600 | 64 | – | – | – | 1679 | – | – | – | – | – | – | – | – |

| 1700 | 68 | – | – | – | 1869 | – | – | – | – | – | – | – | – |

| 1800 | 72 | – | – | – | 2126 | – | – | – | – | – | – | – | – |

| 1900 | 76 | – | – | – | 2372 | – | – | – | – | – | – | – | – |

| 2000 | 80 | – | – | – | 2626 | – | – | – | – | – | – | – | – |

90 dị ogologo dị ogologo na-ada na carbon carbon steelt

Ọrụ nke Bold Weld Hakight bụ ịgbanwe nduzi ma ọ bụ banye na sistemụ piping. Enwere 45 Celsius, 90 Celsius na 180 Celsius.

- Enwere ụdị nke 90 nke 90 nke 90: lr (ogologo radius), sr (obere radius) na-eme ka ọ dị oke mma na-enwe ọfụma.

- Carbon luw Beld Beed bụ nke ASME B16.9 FIPE BITEDICER, a na-enwe ikike iji nweta ihe dị iche iche.

- Na-achagharị, ma ọ bụ na-agagharị, bụ usoro na-emepụta ebe etinyere mkpuchi nke zinc ma ọ bụ ígwè iji chebe onwe ya ma na-egbochi. Enwere ọtụtụ ndị na-agagharị uche dị, mana a na-akpọ usoro a na-enyekarị na usoro eji akpọ ọkụ.

Bosian

Lr na-eme ka ọ dị mma