Baja stainless duplex

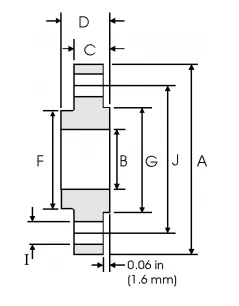

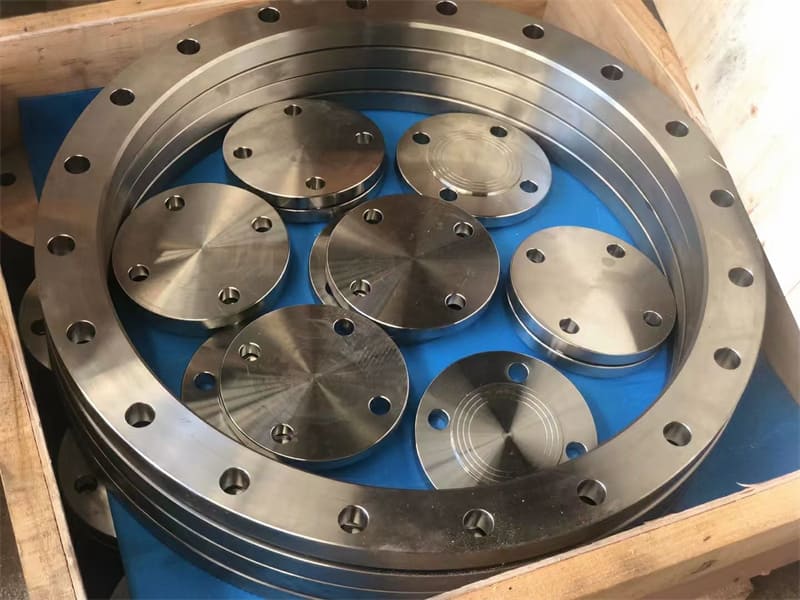

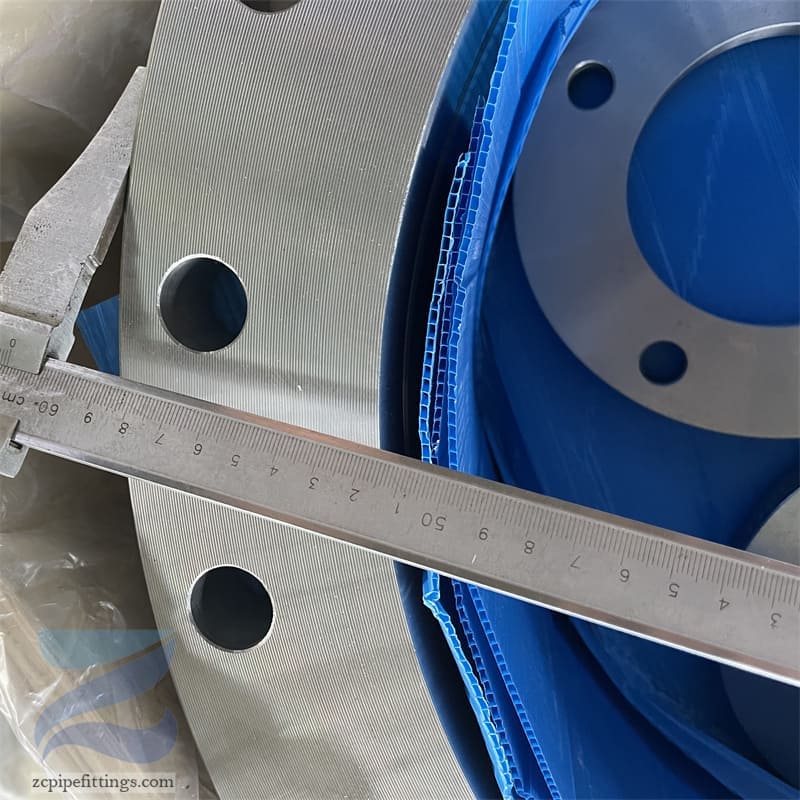

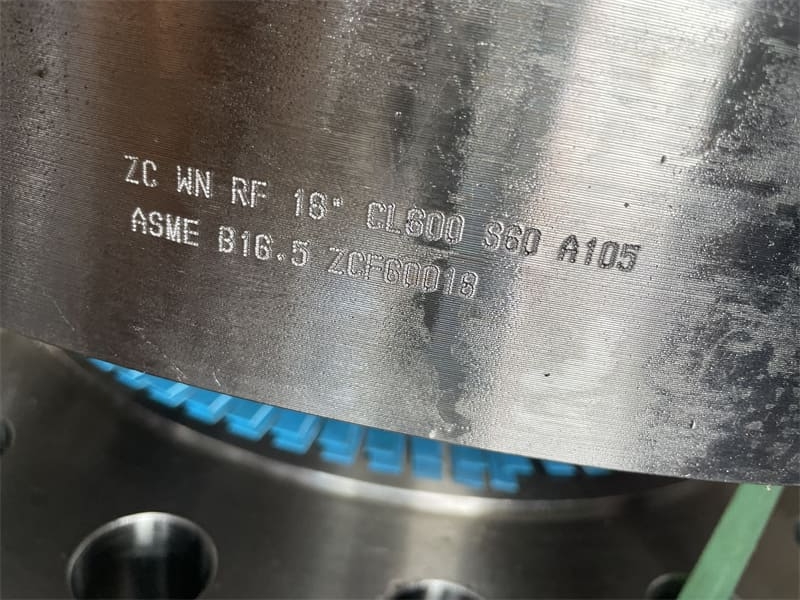

Asme b16. 5 diwatesi kanggo flanges lan flanged bahan sing digawe saka bahan cast utawa fLEGED, lan flanger buta lan bahan-bahan sing digawe saka cast, utawa piring. Uga kalebu ing standar kasebut yaiku syarat lan rekomendasi babagan bolting flange, gasket flange, lan sendi flange.

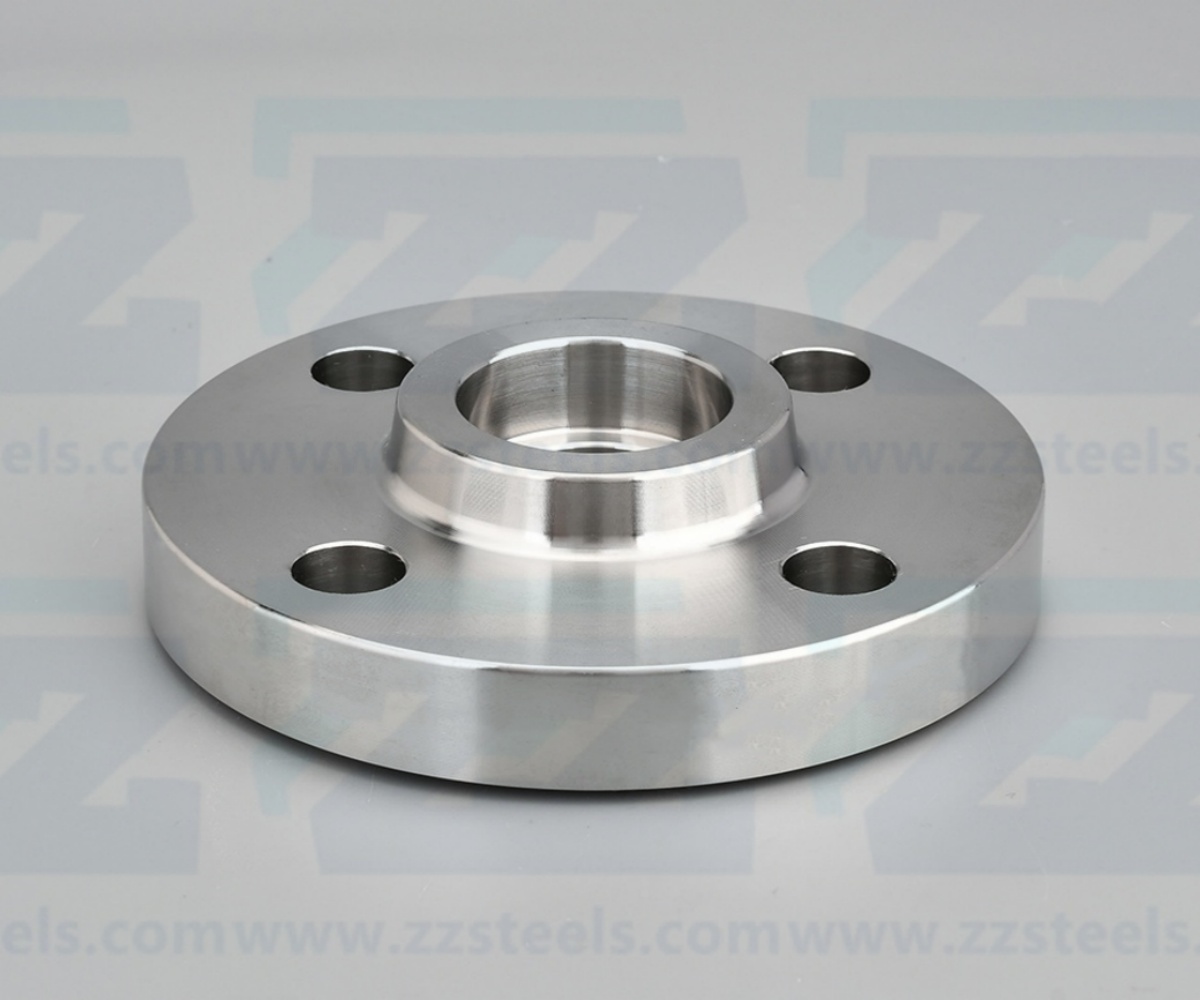

Slip ing flange, uga diarani flange. Iku jinis slide flange ing pipa kanthi desain internal rada gedhe tinimbang pipa. Wiwit diameter batin saka flange rada gedhe tinimbang diameter diameter pipa, sing dadi flange bisa langsung nyambung karo peralatan utawa pipa kanthi illet weld ing sisih ndhuwur lan ngisor flange. Iki digunakake kanggo masang pipa menyang bolongan batin flange.

Buta tontonan kasebut, uga dikenal minangka plate buta utawa platokan plato khusus, yaiku komponen khusus sing digunakake ing sistem pipo. Iki digunakake ing kebon industri, utamane ing kimia, minyak, gas alami lan industri liyane.