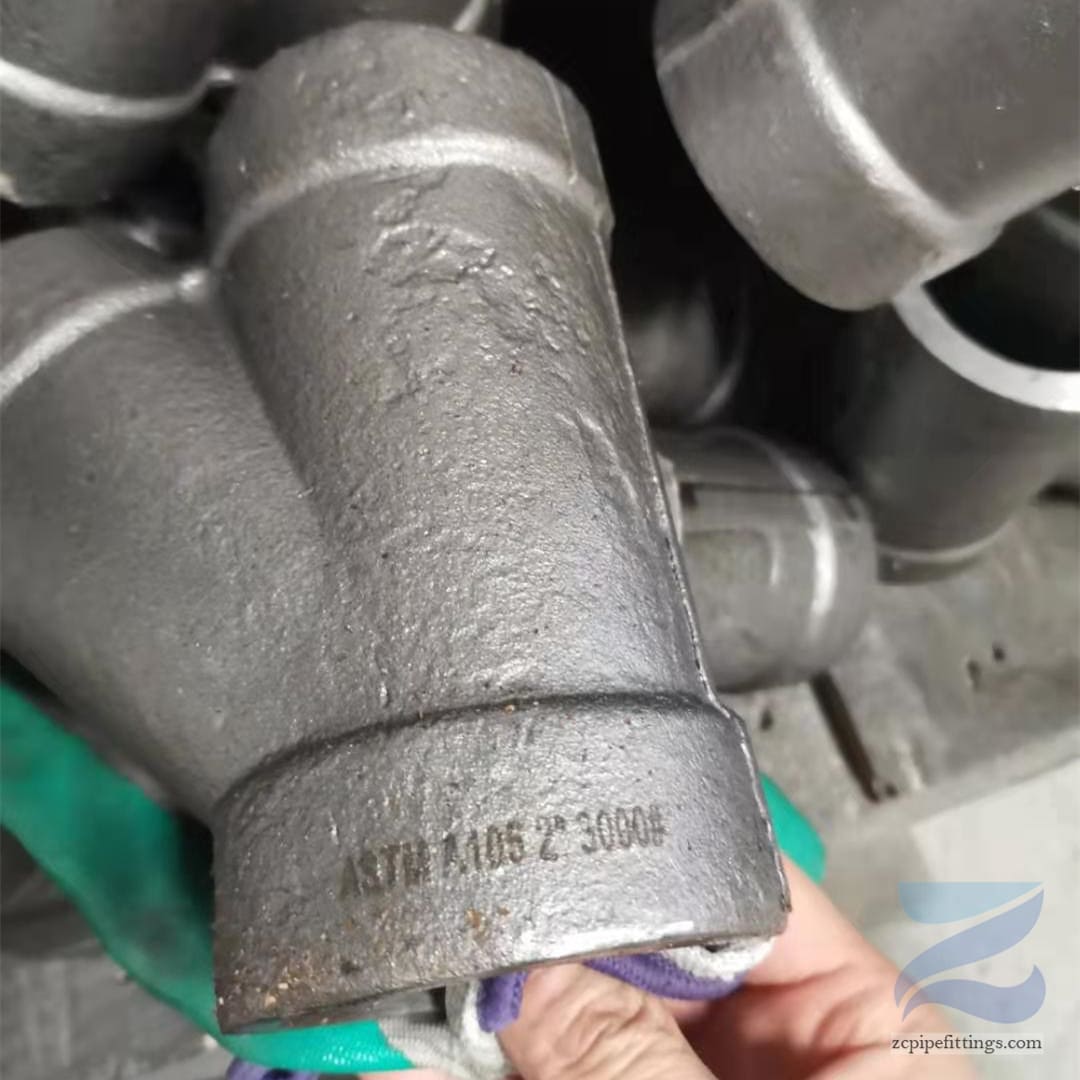

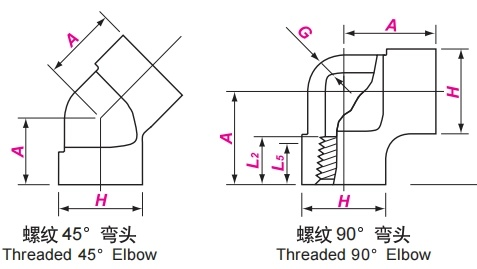

A182 Ditunjukkeun Pelu mangrupikeun pipi pipa anu ngarobih arah pipa. A182 mangrupikeun diatur standar ku masarakat Amérika ieu kanggo pemuji sareng bahan (Asstm), anu utar-kuipkeun bijil, dipulung. Dina sistem standar ieu, milari elbows gaduh peraturan kana bahan-bahan sareng prosés produkaktun, akurasi diménsi, jssibrance.

Ibu A182 sabab larutan loba dipaké dina widang industri sapertos minyak bumi, kakuatan listrik, kakuatan listrik, sareng pasang pikeun nyambung pipa sareng ngarobah arah pipa. Ngahasilkeun elewa dilakukeun nganggo prosés pikaresepeun, supados aranjeunna ngagaduhan kakuatan sareng tanggung jawab sareng tanggung jawab sareng tiasa tahan tekanan anu luhur. Salaku tambahan, aranjeunna ngagaduhan akurasi manufaktur anu luhur, dimensi stabil, pamasihan, sareng kahirupan jasa panjang.

Nepali

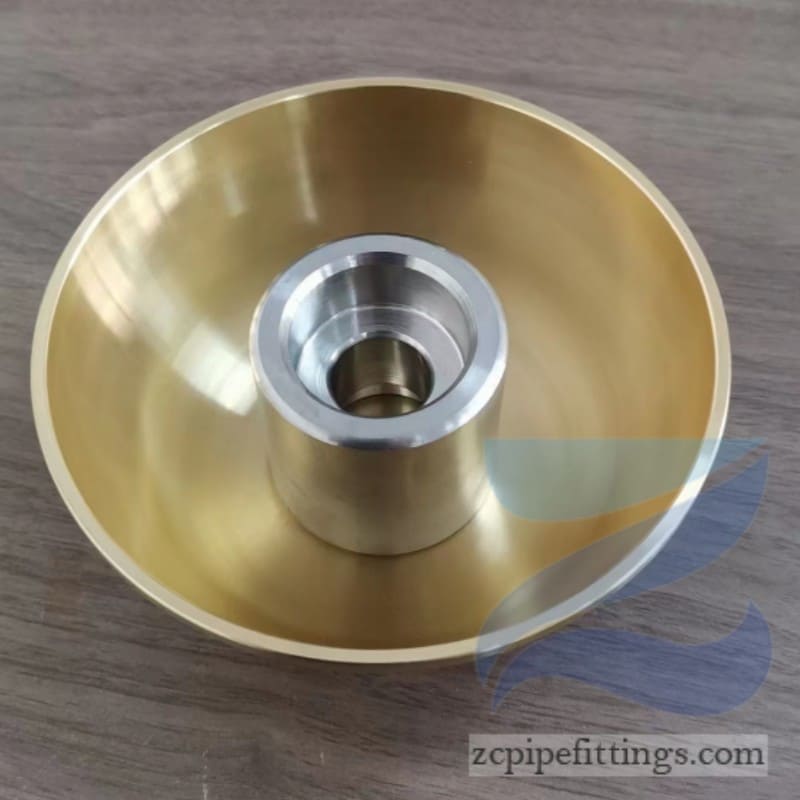

Bex Beelless SteTM A182 F51, F53, F44

Nepali

| Khmer | Asme B16.11 6in 3000 # Bisnis Weld |

| Azerbajani | ASTM A182 stopét stopét weld couns mss mss sp 97 |

| Stops weld fitning | A182 SS304L Sockeolet Bank |

| Tukang ngaopo | Stops leldis narik |

| Panjang benang | Kumaha tas toko stops sareng klasifikasi stoptétel helu |

| Beusi sténless | Stanks stainless astma A182 f304l Citakan: gandeng |

| Asme B16.11, BS3799 | Naon anu dipilampah sareng kumaha upami ukuran sareng spésifikasi |

Nepali

ASME B16.11 pipis stoptings

Nepali

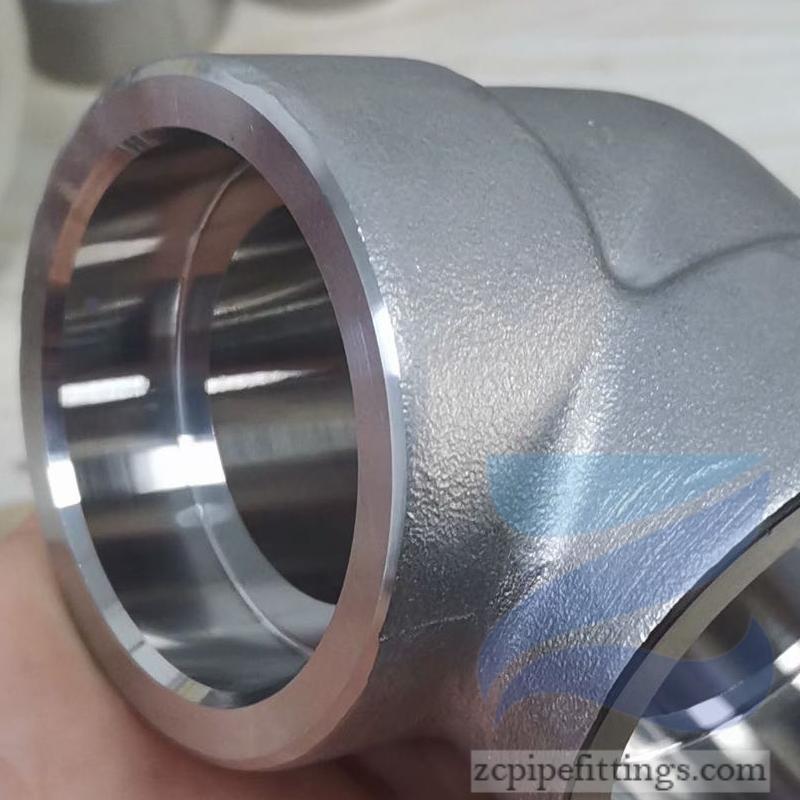

Dropcilih Weld 90oo direncanakeun pikeun teuing dianggo pikeun industri anu béda sapertos aturan minyak minyak, Procochicompet, pelekokimia séjén, puncaknaal.

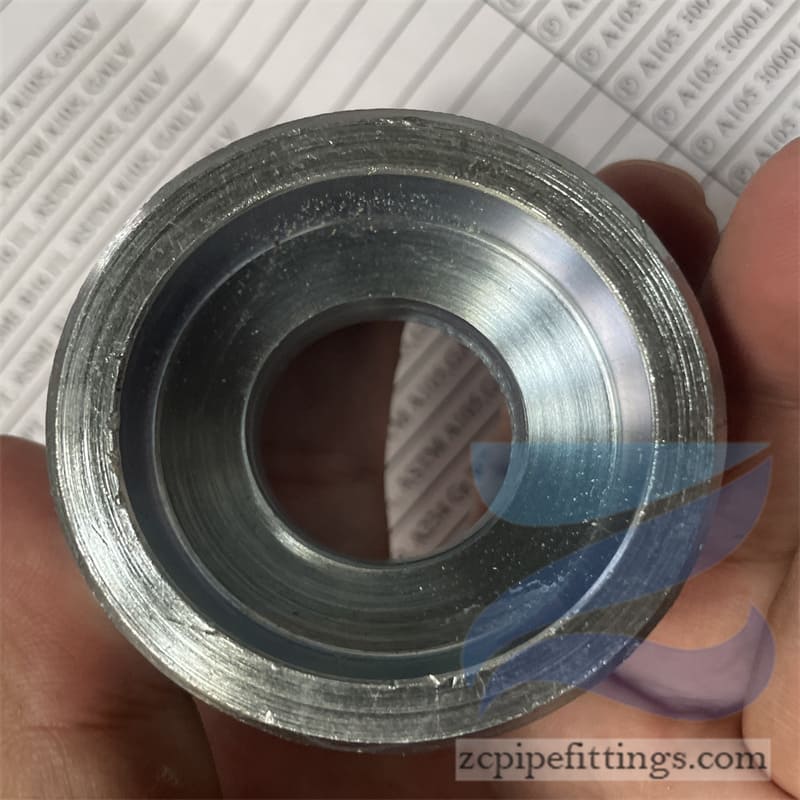

Firstops Shoppings Helu nyaéta ANTARA GAMPANG PEPIK PIPIK dimana pipa diselapkeun kana daérah anu dikintunkeun tina klep, pas atanapi fitte. Sakali diselapkeun, eusian jenis welding segel anu dilarapkeun pikeun ngiluan pipa ka pas.

Nepali

| Thai | Imah | Urdu | Igbo | Zulu | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| Bentukna | Link: | Bentukna | Link: | Bentukna | Link: | ||||||

| 6 | 0.125 | 10.9 | 2.41 | 3.15 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – |

| 8 | 0.25 | 14.3 | 3.02 | 3.68 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – |

| 10 | 0.375 | 17.7 | 3.2 | 4.01 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – |

| 15 | 0.5 | 21.9 | 3.73 | 4.78 | 7.47 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 0.75 | 27.3 | 3.91 | 5.56 | 7.82 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34 | 4.55 | 6.35 | 9.09 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 1.25 | 42.8 | 4.85 | 6.35 | 9.7 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 1.5 | 48.9 | 5.08 | 7.14 | 10.15 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 5.54 | 8.74 | 11.07 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 |

| 65 | 2.5 | 73.9 | 7.01 | – | – | 8.16 | 7.62 | – | – | – | – |

| 80 | 3 | 89.9 | 7.62 | – | – | 9.52 | 8.3 | – | – | – | – |

| 100 | 4 | 115.5 | 8.56 | – | – | 10.69 | 9.35 | – | |||

| Pilih basa | Myanmar (Burmese) | Baja karbon: Asma A105 \ / A105n | Kurdish (Kurmanji) | Buttwelding fitning | |||||||

| Thai | Imah | GmIN | Tel: | XHOSA | Arménia | Georgia | |||||

| Baja alloy | Taros Kami | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

Nepali

Nepali

Asme B16.11 Balch Seld

Nepali

A182 Ditunjukkeun Pelu mangrupikeun pipi pipa anu ngarobih arah pipa. A182 mangrupikeun diatur standar ku masarakat Amérika ieu kanggo pemuji sareng bahan (Asstm), anu utar-kuipkeun bijil, dipulung.

Kami ngagaduhan dina manufaktur profésional tina Dzme Up6.11 Copplock Cetlock Caspada, nganggo bahan bédana sapertos Kares karboh, baja aloino, sareng alhi asa.

Pariksa bentuk palabuhan siku, anu kedah datar sareng jejeg ka sumbu pikeun mastikeun docking anu saé kalayan pipa anu sanés.