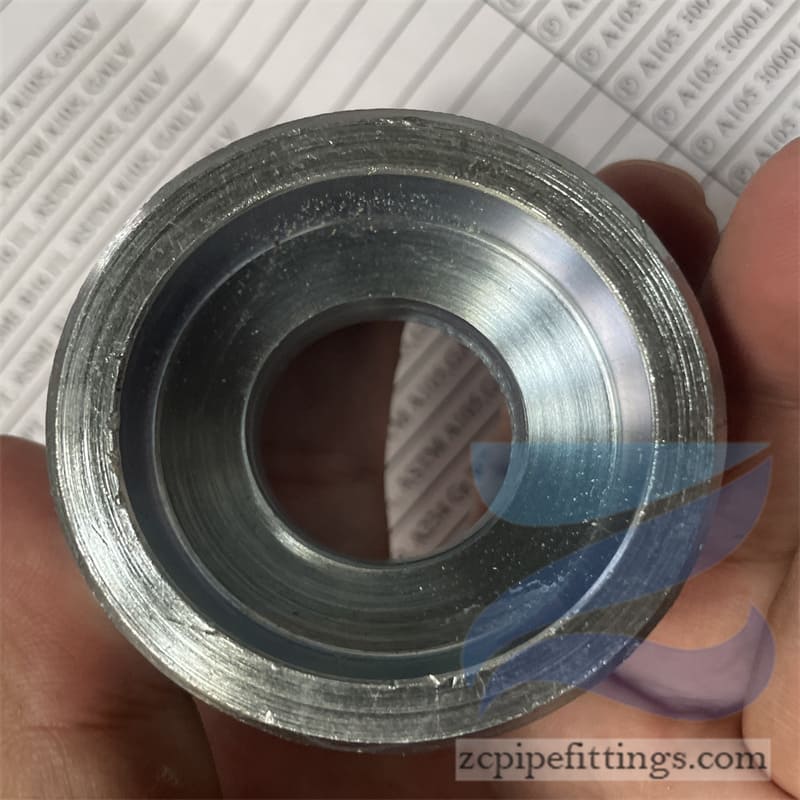

BSP 1 INCH Socket Half Coupling

Angalia uso wa viwiko vya kughushi vya A182 kwa kasoro kama nyufa, kasoro, na ngozi nzito. Nyufa zinaweza kusababishwa na mkusanyiko wa mafadhaiko wakati wa mchakato wa kughushi au kasoro katika malighafi, wakati kasoro na ngozi nzito zinaweza kuathiri umoja wa unene wa ukuta na nguvu ya kiwiko.

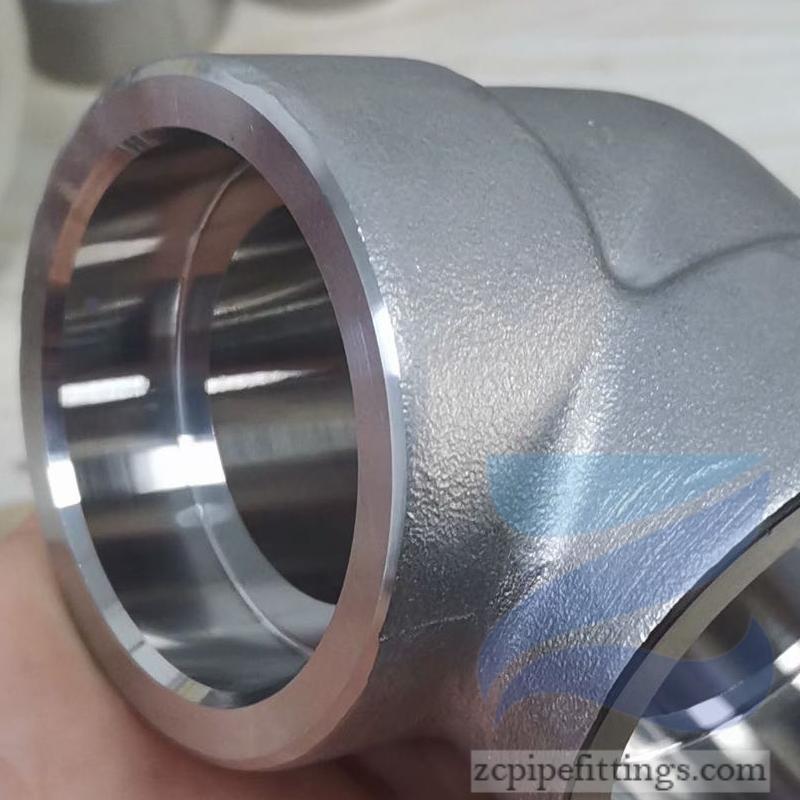

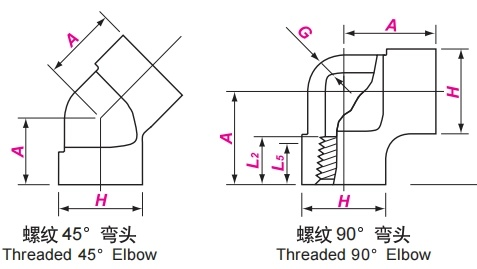

A182 Elbow ya kughushi ni bomba linalofaa ambalo hubadilisha mwelekeo wa bomba. A182 ni kiwango kilichowekwa na Jumuiya ya Amerika ya Upimaji na Vifaa (ASTM), ambayo inashughulikia chuma cha kughushi au kilichovingirishwa na bomba la chuma cha pua, vifaa vya kughushi vya bomba, valves na sehemu za matumizi ya joto la juu. Chini ya mfumo huu wa kawaida, viwiko vya kughushi vina kanuni za kina juu ya vifaa vyao, michakato ya utengenezaji, usahihi wa sura, mahitaji ya utendaji, nk.

Viwiko vya kughushi vya A182 vinatumika sana katika uwanja wa viwandani kama vile mafuta, kemikali, nguvu ya umeme, na ujenzi wa meli ili kuunganisha bomba na ubadilishe mwelekeo wa bomba. Viwiko vya kughushi vinafanywa kwa kutumia mchakato wa kutengeneza, kwa hivyo wana nguvu kubwa na ugumu na wanaweza kuhimili shinikizo kubwa. Kwa kuongezea, wana usahihi wa utengenezaji wa hali ya juu, vipimo thabiti, usanikishaji rahisi, na maisha marefu ya huduma.

Nepali

ASTM A182 F11 \ / F12 \ / F5 \ / F9 \ / F91 \ / F92 \ / F22

Nepali

| Khmer | Chuma cha chini cha kaboni: ASTM A350 LF2 \ / LF3 |

| Azerbaijani | Chuma cha Alloy: ASTM A182 F11 \ / 12 \ / 5 \ / 9 \ / 91 \ / 92 \ / 22 |

| Vipimo vya ASME B16.11 | 1 \ / 2 ″ END END CAP ~ SS304 Fittings za chuma cha pua |

| Galician | Vipimo zaidi vya weld |

| Urefu wa uzi | Je! Ni socket weld uninon, vipi kuhusu uboreshaji wake na faida |

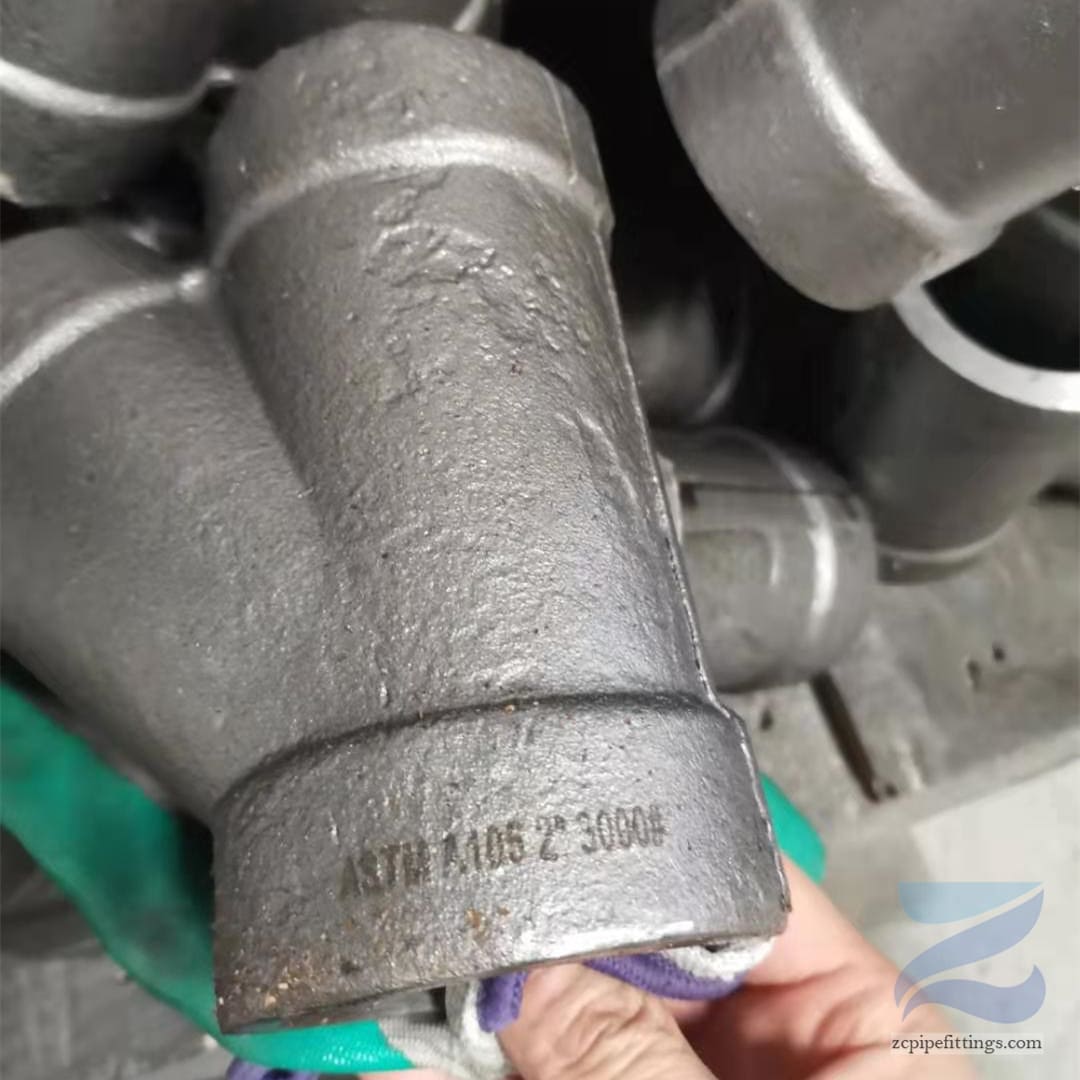

| Chuma cha pua | Socket kulehemu tee 1 \ / 8 ″ -4 ″ chuma cha kaboni ASTM A105 |

| Socket Weld Fittings | 90 Deg Socket Weld Elbows ASME B16.11 Fittings za bomba la pua |

Nepali

A182 F316 Fittings chuma cha pua

Nepali

Sisi wataalam katika utengenezaji wa kitaalam wa ASME B16.11 socket weld tees, kwa kutumia vifaa vya hali ya juu kama vile chuma cha kaboni, chuma cha pua, na chuma cha aloi.

Vipodozi vya weld ya tundu ni maelezo ya kiambatisho cha bomba ambayo bomba limeingizwa kwenye eneo lililowekwa tena la valve, linalofaa au flange. Mara tu ikiwa imeingizwa kwa usahihi, welds za kuziba za aina ya fillet hutumiwa ili kujiunga na bomba kwa kufaa.

Nepali

| Thai | Nyumbani | Urdu | Igbo | Zulu | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| Sura | Unganisha: | Sura | Unganisha: | Sura | Unganisha: | ||||||

| 6 | 0.125 | 10.9 | 2.41 | 3.15 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – |

| 8 | 0.25 | 14.3 | 3.02 | 3.68 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – |

| 10 | 0.375 | 17.7 | 3.2 | 4.01 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – |

| 15 | 0.5 | 21.9 | 3.73 | 4.78 | 7.47 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 0.75 | 27.3 | 3.91 | 5.56 | 7.82 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34 | 4.55 | 6.35 | 9.09 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 1.25 | 42.8 | 4.85 | 6.35 | 9.7 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 1.5 | 48.9 | 5.08 | 7.14 | 10.15 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 5.54 | 8.74 | 11.07 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 |

| 65 | 2.5 | 73.9 | 7.01 | – | – | 8.16 | 7.62 | – | – | – | – |

| 80 | 3 | 89.9 | 7.62 | – | – | 9.52 | 8.3 | – | – | – | – |

| 100 | 4 | 115.5 | 8.56 | – | – | 10.69 | 9.35 | – | |||

| Chagua lugha | Vipimo vya ASTM A182 | Chuma cha kaboni: ASTM A105 \ / A105N | Kiwango: MSS SP-97 | Vipodozi vya chuma vya kughushi | |||||||

| Thai | Nyumbani | Gmin | Simu: | Xhosa | Armenia | Kijojiajia | |||||

| Chuma cha alloy | Wasiliana nasi | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

Nepali

Nepali

ASME B16.11 Uainishaji wa kiwiko cha kughushi

Nepali

Kusudi kuu la kutumia kofia za bomba ni kuzuia maji. Pia hutumiwa kufunga ncha za bomba za majimaji au nyumatiki na zilizopo. Matumizi ya kofia za bomba la kughushi ni kawaida katika viwanda vingi kama tasnia ya mafuta na gesi, viwanda vya kemikali na mistari ya usambazaji wa maji.

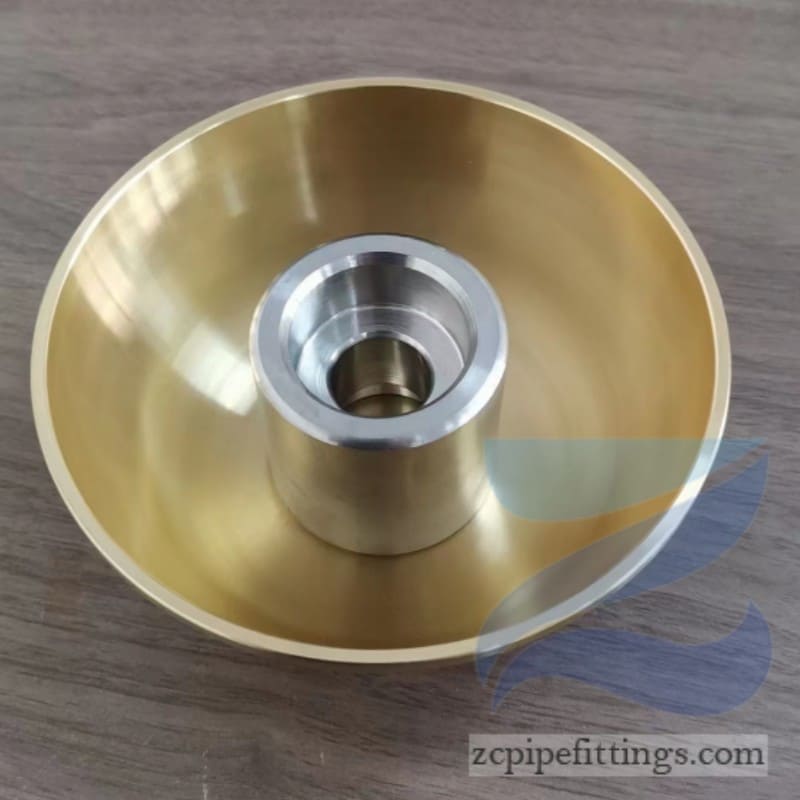

Vipodozi vya bomba la chuma isiyo na waya ikiwa ni pamoja na tee, msalaba, kiwiko, kipunguzi, coupling, chuchu, kuziba & cap, umoja.Haweza kushikamana na bomba na kulehemu, tundu na nyuzi.

Angalia sura ya bandari ya kiwiko, ambayo inapaswa kuwa gorofa na ya kawaida kwa mhimili ili kuhakikisha kuwa docking nzuri na bomba la karibu.