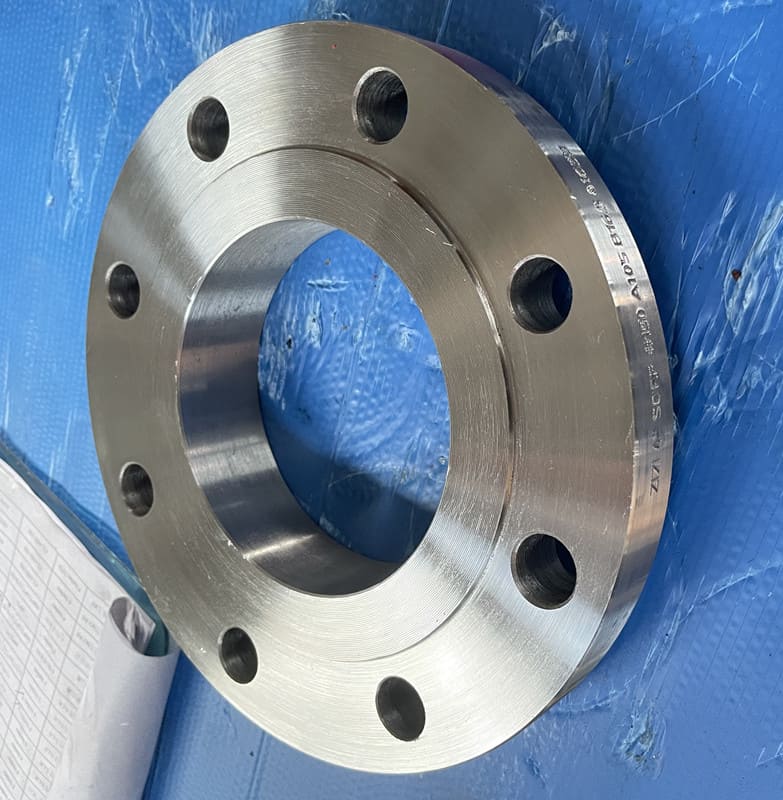

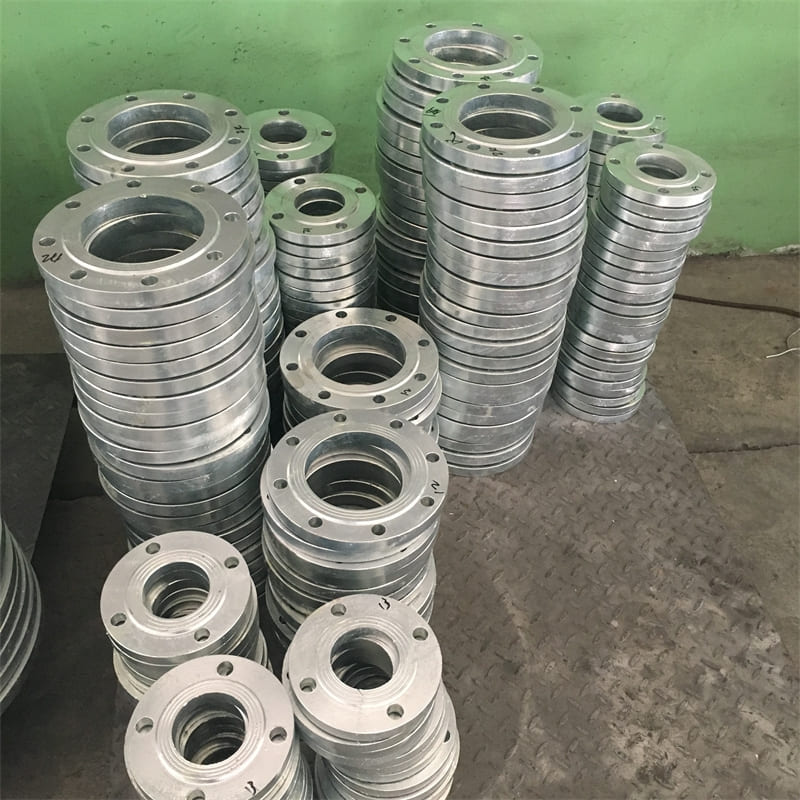

Carbon chuma lap pamoja flange

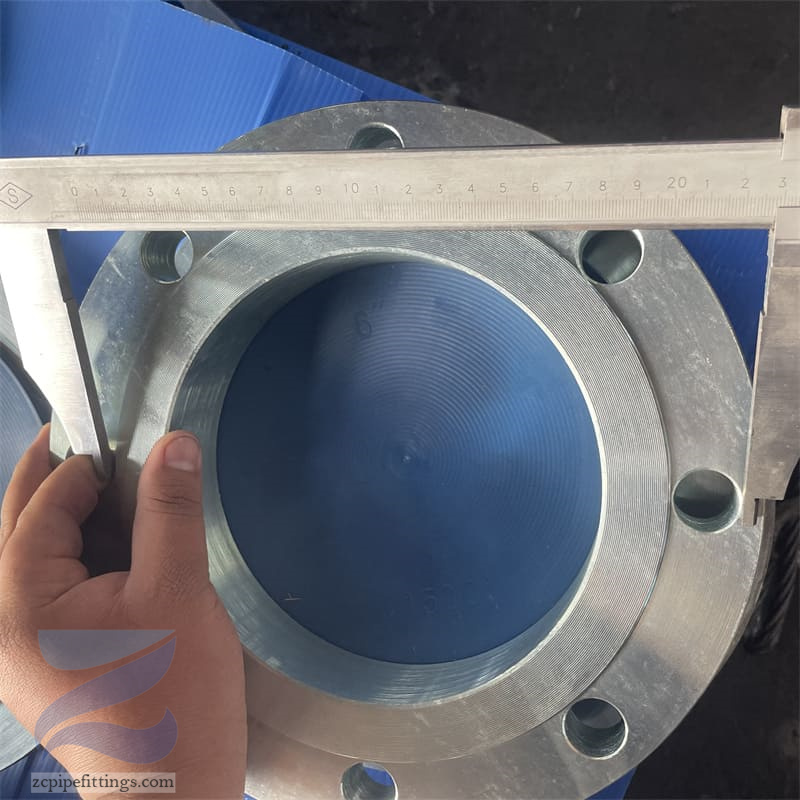

Njia ya unganisho ya flange ya tundu la A182 F11 ni kuingiza bomba kwenye tundu la flange, na kisha kuiweka muhuri kwa kulehemu au kutumia gasket ya kuziba. Njia hii ya unganisho ni nguvu na inaweza kuzoea upanuzi wa mafuta na contraction ya bomba kwa kiwango fulani.

Njia ya unganisho ya flange ya tundu la A182 F11 ni kuingiza bomba kwenye tundu la flange, na kisha kuiweka muhuri kwa kulehemu au kutumia gasket ya kuziba. Njia hii ya unganisho ni nguvu na inaweza kuzoea upanuzi wa mafuta na contraction ya bomba kwa kiwango fulani.

Flanges za pamoja za chuma za kaboni hutumiwa sana katika nyanja nyingi, kama vile vifaa vya ujenzi, tasnia ya petroli, mimea ya nguvu ya mafuta, tasnia ya dawa, na ujenzi wa meli. Mabomba na vifaa katika uwanja huu mara nyingi vinahitaji kuhimili shinikizo tofauti, joto na vyombo vya habari, na utofauti na uwezo wa kubadilika kwa taa za pamoja za kaboni zinawawezesha kukidhi mahitaji ya unganisho chini ya hali hizi ngumu.

Bomba la shinikizo la juu F304 Frange ya chuma ya kughushi

| (Kiingereza) | ASTM A182 chuma cha pua Flange wn Flange kuchora |

| Haiti Creole | Alloy Steel A182 Vipimo vya Tee |

| Kipenyo | Kikurdi (Kurmanji) |

| Mabomba ya chuma | Saizi ya bomba la kawaida |

Carbon Steel ASTM A105 Vipimo vya msalaba vilivyofungwa

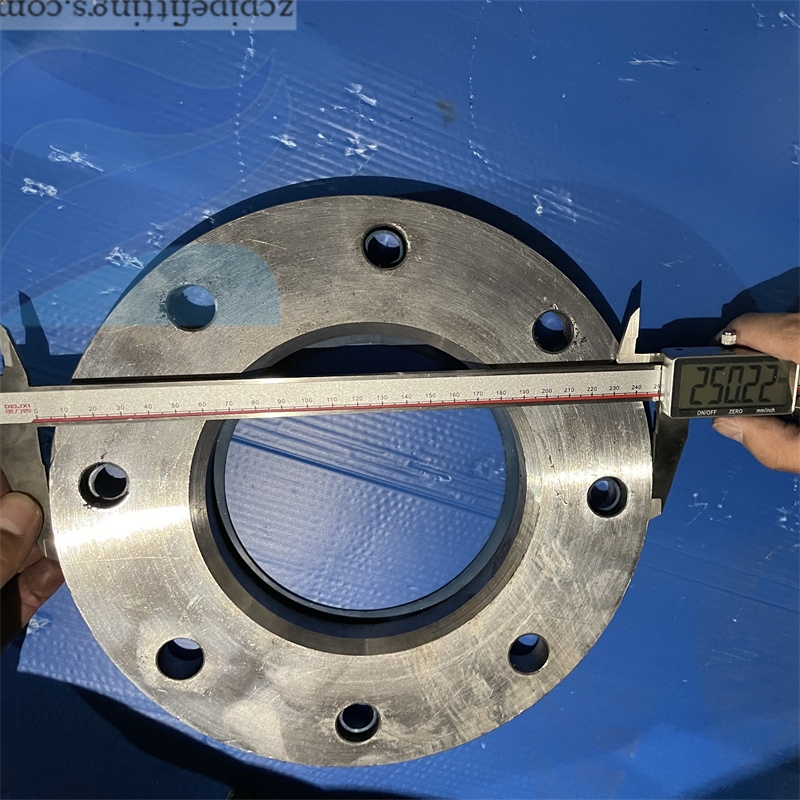

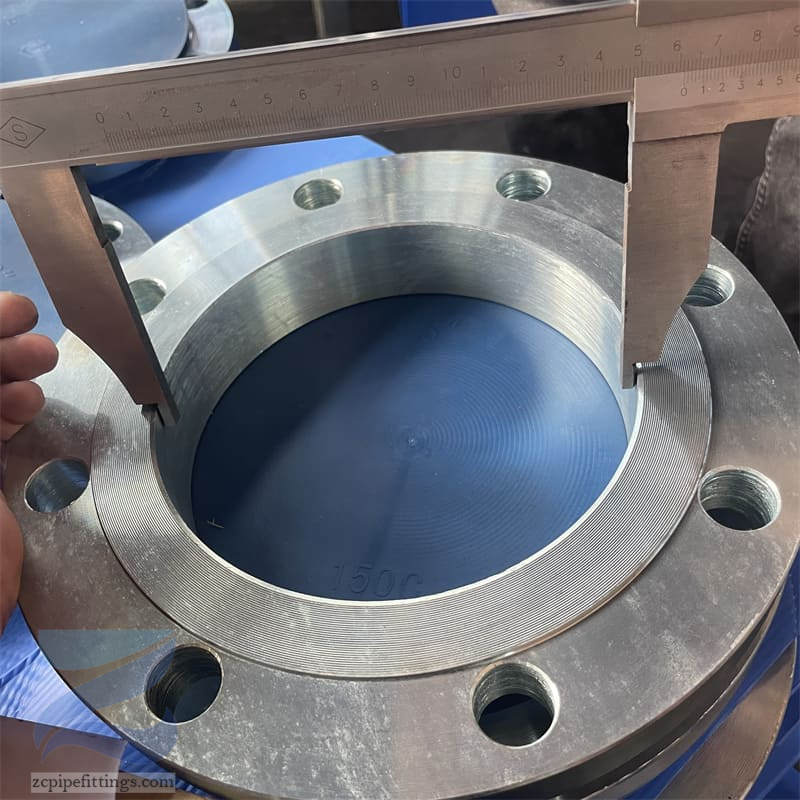

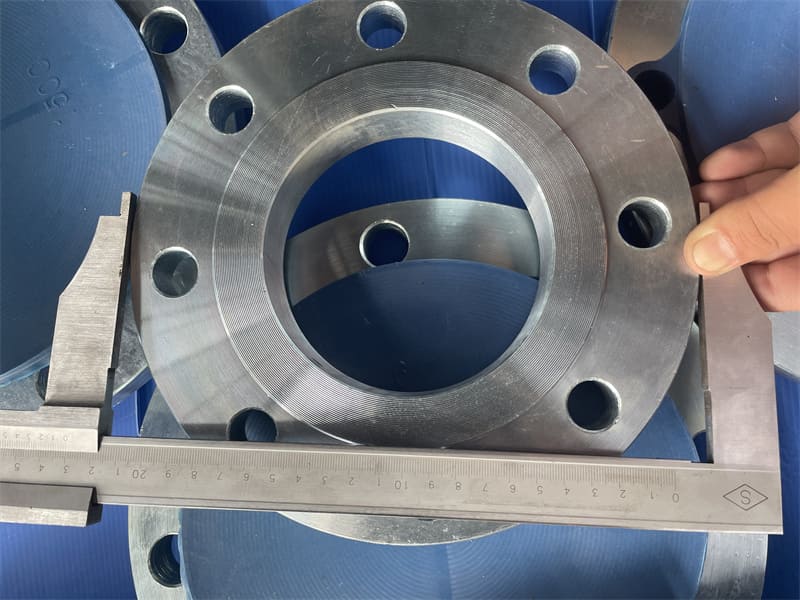

1500 lb Kwa hivyo flanges ni ya shinikizo kubwa flanges.Flanges zina shinikizo nyingi: CL150, CL300, CL600, CL900, CL1500, CL2500.Flange Dimension ina safu kubwa sana ya kukidhi mahitaji tofauti.

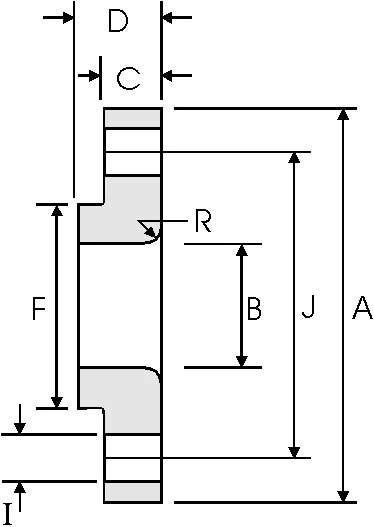

Vipimo vya darasa 900

| Maoni ya Wateja | Kwa jumla | Uchunguzi | Flange | Urefu | Uchunguzi | Hub | kg \ / | Shimo la bolt | Unene | ya mashimo | min |

| ya mashimo | ya mashimo | ya mashimo | ya duara | Radius | Jinsi ya | ya mashimo | Sehemu | ya mashimo | Paja la pamoja | Arbon | |

| Kicheki | Kicheki | Kicheki | katika | Kicheki | Kicheki | Kicheki | Kicheki | Kicheki | Kicheki | ||

| mm | mm | mm | mm | mm | mm | mm | Kicheki | mm | mm | Kicheki | |

| I | I | I | I | I | I | I | Kicheki | I | I | Kicheki | |

| 1/2 | 0.84 | 4.75 | 0.9 | 0.88 | 1.25 | 0.12 | 1.5 | 4 | 0.88 | 3.25 | 1.71 |

| 21.3 | 120.6 | 22.9 | 22.3 | 31.7 | 3 | 38.1 | 22.3 | 82.5 | |||

| 3/4 | 1.05 | 5.12 | 1.11 | 1 | 1.38 | 0.12 | 1.75 | 4 | 0.88 | 3.5 | 2.3 |

| 26.7 | 130 | 28.2 | 25.4 | 35 | 3 | 44.4 | 22.3 | 88.9 | |||

| 1 | 1.32 | 5.88 | 1.38 | 1.12 | 1.62 | 0.12 | 2.06 | 4 | 1 | 4 | 3.4 |

| 33.4 | 149.3 | 35.1 | 28.4 | 41.1 | 3 | 52.3 | 25.4 | 101.6 | |||

| 1 1/4 | 1.66 | 6.25 | 1.72 | 1.12 | 1.62 | 0.19 | 2.5 | 4 | 1 | 4.38 | 3.85 |

| 42.2 | 158.7 | 43.7 | 28.4 | 41.1 | 4.8 | 63.5 | 25.4 | 111.2 | |||

| 1 1/2 | 1.9 | 7 | 1.97 | 1.25 | 1.75 | 0.25 | 2.75 | 4 | 1.12 | 4.88 | 5.28 |

| 48.3 | 177.8 | 50 | 31.7 | 44.4 | 6.4 | 69.85 | 28.4 | 123.9 | |||

| 2 | 2.38 | 8.5 | 2.46 | 1.5 | 2.25 | 0.31 | 4.12 | 8 | 1 | 6.5 | 9.78 |

| 60.3 | 215.9 | 62.5 | 38.1 | 57.15 | 7.9 | 104.6 | 25.4 | 165. 1 | |||

| 2 1/2 | 2.88 | 9.62 | 2.97 | 1.62 | 2.5 | 0.31 | 4.88 | 8 | 1.12 | 7.5 | 13.6 |

| 73 | 244.3 | 75.4 | 41.1 | 63.5 | 7.9 | 123.9 | 28.4 | 190.5 | |||

| 3 | 3.5 | 9.5 | 3.6 | 1.5 | 2. 120 | 0.38 | 5 | 8 | 1 | 7.5 | 11.3 |

| 88.9 | 241.3 | 91.4 | 38.1 | 53.8 | 9.7 | 127 | 25.4 | 190.5 | |||

| 4 | 4.5 | 11.5 | 4.6 | 1.75 | 2.75 | 0.44 | 6.25 | 8 | 1.25 | 9.25 | 19.2 |

| 114.3 | 292.1 | 116.8 | 44.4 | 69.85 | 11.2 | 158.7 | 31.7 | 234.9 | |||

| 5 | 5.56 | 13.75 | 5.69 | 2 | 3. 120 | 0.44 | 7.5 | 8 | 1.38 | 11 | 31.2 |

| 141.3 | 349.2 | 114.5 | 50.8 | 79.25 | 11.2 | 190.5 | 35 | 279.4 | |||

| 6 | 6.63 | 15 | 6.75 | 2.19 | 3.38 | 0.5 | 9.25 | 12 | 1.25 | 12.5 | 40.5 |

| 168.3 | 381 | 171.5 | 55.6 | 85.8 | 12.7 | 234.9 | 31.7 | 317.5 | |||

| 8 | 8.63 | 18.5 | 8.75 | 2.5 | 4.5 | 0.5 | 11.75 | 12 | 1.5 | 15.5 | 71.5 |

| 219.1 | 469.9 | 222.3 | 63.5 | 114.3 | 12.7 | 298.4 | 38.1 | 393.7 | |||

| 10 | 10.75 | 21.5 | 10.92 | 2.75 | 5 | 0.5 | 14.5 | 16 | 1.5 | 18.5 | 104 |

| 273 | 546.1 | 277.4 | 69.85 | 127 | 12.7 | 368.3 | 38.1 | 469.9 | |||

| 12 | 12.75 | 24 | 12.92 | 3.12 | 5.62 | 0.5 | 16.5 | 20 | 1.5 | 21 | 139 |

| 323.8 | 609.6 | 328.2 | 79.25 | 142.7 | 12.7 | 419.1 | 38.1 | 533.4 | |||

| 14 | 14 | 25.25 | 14.18 | 3.38 | 6. 120 | 0.5 | 17.75 | 20 | 1.62 | 22 | 161 |

| 355.6 | 641.3 | 360.2 | 85.8 | 155.4 | 12.7 | 450.8 | 41.1 | 558.8 | |||

| 16 | 16 | 27.75 | 16.19 | 3.5 | 6.5 | 0.5 | 20 | 20 | 1.75 | 24.25 | 194 |

| 406.4 | 704.8 | 411.2 | 88.9 | 165.1 | 12.7 | 508 | 44.4 | 615.9 | |||

| 18 | 18 | 31 | 18.2 | 4 | 7.5 | 0.5 | 22.25 | 20 | 2 | 27 | 267 |

| 457.2 | 787.4 | 462.3 | 101.6 | 190.5 | 12.7 | 565.1 | 50.8 | 685.8 | |||

| 20 | 20 | 33.75 | 20.25 | 4.25 | 8.25 | 0.5 | 24.5 | 20 | 2.12 | 29.5 | 334 |

| 508 | 857.2 | 514.4 | 107.9 | 209.5 | 12.7 | 622.3 | 53.8 | 749.3 | |||

| 24 | 24 | 41 | 24.25 | 50.5 | 10.5 | 0.5 | 29.5 | 20 | 2.62 | 35.5 | 618 |

| 609.6 | 1041.4 | 616 | 139.7 | 266.7 | 12.7 | 749.3 | 66.55 | 901.7 |

nstallC SLangeFSimu:Whatsapp: Unganisha:

Kwanza, unganisha kaboni ya chuma ya kaboni na flange ya bomba au vifaa vingine, na uhakikishe kuwa shimo na mashimo ya bolt ya flange mbili yameunganishwa. Weka gasket inayofaa kati ya flanges. Nyenzo na unene wa gasket inapaswa kuchaguliwa kulingana na hali kama vile kati, joto na shinikizo. Gasket inapaswa kuwekwa kwenye uso wa kuziba na kuhakikisha kuwa ni gorofa na haina kasoro. Mwishowe, ingiza bolts ndani ya shimo la bolt moja kwa moja, ukizingatia mwelekeo na msimamo wa bolts ili kuhakikisha kuwa bolts zinaweza kukazwa vizuri. Tumia zana kama vile wrenches kaza bolts hapo awali, na kuwa mwangalifu kutumia nguvu sawasawa ili kuzuia sehemu juu ya kuimarisha au kufunika zaidi. Baada ya kudhibitisha kuwa msimamo ni sawa, tumia zana kama vile wrenches kukaza bolts kwa mara ya mwisho.

Kicheki

Kicheki