Inkqubo yePhekami yePhemikhali

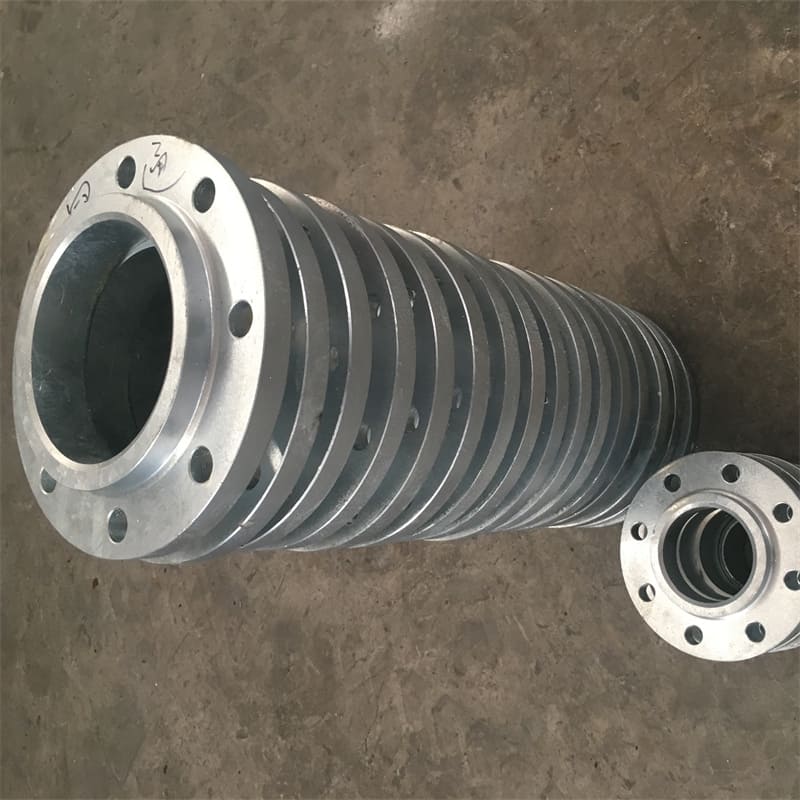

I-Slip yesiliphu iya kunika isixa esininzi sendawo yombhobho wokuthelekisa. Oku kuvumela indawo eyaneleyo yokusebenza kwe-welder kunye nelaphulelo ukwenza unxibelelwano.Slip-kwiflethi idla ngokuhlala phantsi kwixabiso le-Wool-Ingoma.

I-Slip yesiliphu iya kunika isixa esininzi sendawo yombhobho wokuthelekisa. Oku kuvumela indawo eyaneleyo yokusebenza kwe-welder kunye nelaphulelo ukwenza unxibelelwano.Slip-kwiflethi idla ngokuhlala phantsi kwixabiso le-Wool-Ingoma.

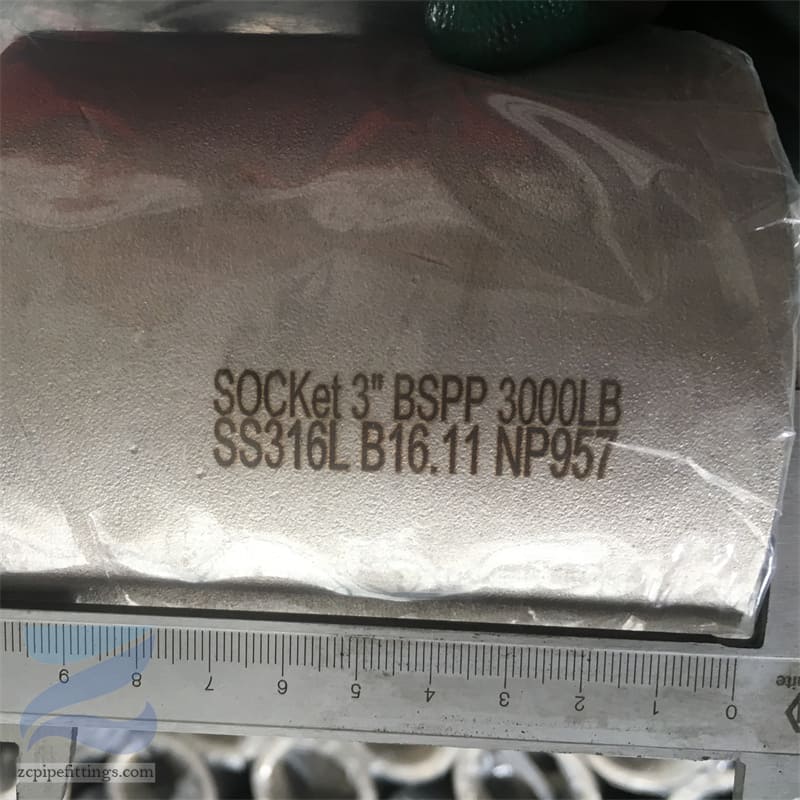

Iiflethi ze-carbon zentsholongwane zisetyenziswa ngokubanzi kwimimandla emininzi efana namaziko okwakha, iPetrochemicals, izityalo zamandla e-thermal, kunye nendawo yokuthumela. Imibhobho kunye nezixhobo ezikweli nkalo zihlala zifuna ukumelana noxinzelelo olwahlukileyo, amaqondo obushushu kunye neendlela ezahlukeneyo ze-carbon ze-capbon zenza ukuba zifezekisile iimfuno zonxibelelwano phantsi kwezi meko zinzima.