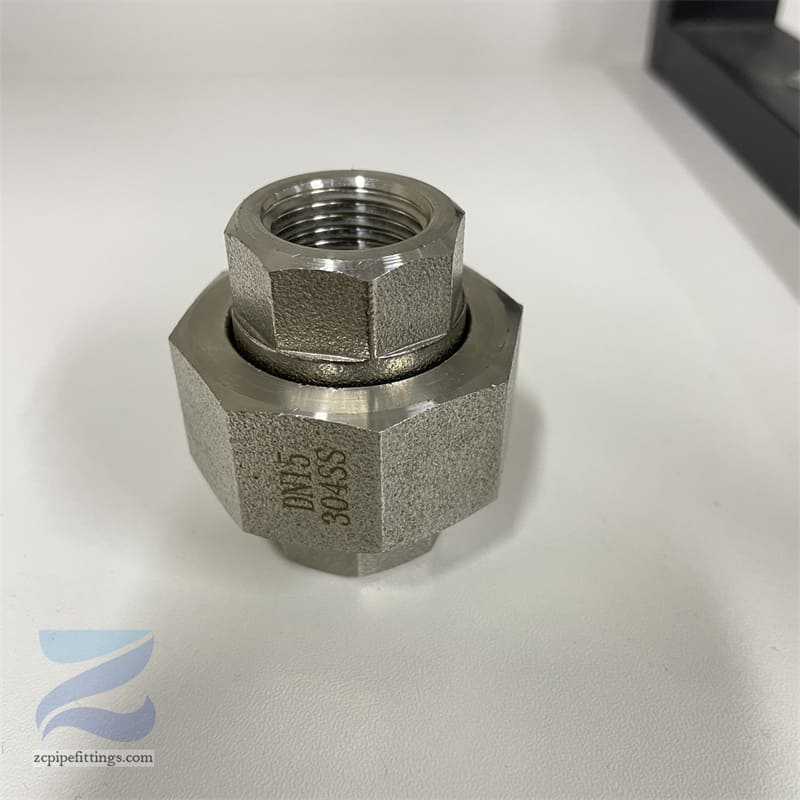

I-ASTM A182 F304 Threaded Union

I-elbow yensimbi engenasici ayi-2'0 Isetshenziselwa ikakhulukazi ukuguqula ukuqondiswa kwepayipi, yenza ipayipi liphenduke amapayipi angama-90, bese uxhuma amapayipi amabili nge-diameters efanayo noma ehlukile.

I-elbow yensimbi engenasici ayi-2'0 Isetshenziselwa ikakhulukazi ukuguqula ukuqondiswa kwepayipi, yenza ipayipi liphenduke amapayipi angama-90, bese uxhuma amapayipi amabili nge-diameters efanayo noma ehlukile.

Ukwakheka kwe-90 ° Elbow kuyingxenye yesiko ngalinye, elinokuxhumana kokuxhuma emikhawulweni yomibili. Izindawo zokuxhumana zisezimweni ezahlukahlukene, kanti ezivamile ziyizindawo zokuhlangana ze-welding, indawo enomugqa, kanye nokuhlangana kwe-flange. I-elbow yensimbi engama-90 Le ndlela yokuxhumeka inokuvalwa okuhle futhi ilungele amasistimu wepayipi eliphakeme kanye namapayipi aphezulu. I-elbow ene-interface ehlanganisiwe ixhunyiwe kupayipi ngokuhlikihla umucu, okulula ukuyifaka futhi ivame ukusetshenziswa ezinhlelweni ezithile zepayipi eliphansi nelincane.

I-MSS SP-97 WeldoletIsiMacedoniaNepali

| IsiMalayalam | Threated hex ingono DN6-DN80 ASME B16.11 |

| Azerbaijani | Izicelo 2 "Izinsimbi Zensimbi Engagqwali |

| I-Malta | I-Socket Welding isebenza kanjani kanye nokuhlukaniswa kweSocket Weld Coupling |

| I-ASME B16.9 I-Elbow | Insimbi engenasici ASTM A182 F304L Socket Weld Coupling |

Thola intengoInpsDn IsiTurkeyOgagalisayo

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559 | 838 | 559 |

| 600 | 24 | 610 | 914 | 610 |

| 650 | 26 | 660 | 991 | 660 |

| 700 | 28 | 711 | 1067 | 711 |

| 750 | 30 | 762 | 1143 | 762 |

| 800 | 32 | 813 | 1219 | 813 |

| 850 | 34 | 864 | 1295 | 864 |

| 900 | 36 | 914 | 1372 | 914 |

| 950 | 38 | 965 | 1447 | 965 |

| 1000 | 40 | 1016 | 1524 | 1016 |

| 1050 | 42 | 1067 | 1600 | 1067 |

| 1100 | 44 | 1118 | 1676 | 1118 |

| 1150 | 46 | 1168 | 1753 | 1168 |

| 1200 | 48 | 1219 | 1829 | 1219 |

| 1300 | 52 | 1321 | 1981 | 1321 |

| 1400 | 56 | 1422 | 2134 | 1422 |

| 1500 | 60 | 1524 | 2286 | 1524 |

| 1600 | 64 | 1626 | 2438 | 1626 |

| 1700 | 68 | 1727 | 2591 | 1727 |

| 1800 | 72 | 1829 | 2743 | 1829 |

| 1900 | 76 | 1930 | 2896 | 1930 |

| 2000 | 80 | 2032 | 3048 | 2032 |

2 "90 degree emgqeni ongenacala

Isiphepheli

Ekukhiqizeni amakhemikhali, amapayipi okulethwa kwamakhemikhali ahlukahlukene ajwayele ukudinga ukushintsha indlela yokugeleza. Ama-elbows ensimbi engenasici angasetshenziswa ezinhlelweni zamapayipi zokudlulisa acidic, alkaline, amagesi alolisayo noma uketshezi. Isibonelo, esitshalweni sokukhiqizwa se-sulfuric acid, ohlelweni lwamapayipi kusuka ku-reactoror ethangini lokugcina, i-90 ℃ Ellow yensimbi ingaqinisekisa ukulethwa okuphephile kwe-sulfuric acid epayipini futhi ivikele ukuvuza kwe-sulfuric acid kusuka ekulimazeni imishini kanye nabasebenzi.

Ukufakwa kwensimbi engenasici

Emanzini atholakalayo kanye namapayipi e-drainage ezakhiwo, ama-90 ℃ ama-elbows ensimbi engenasici asetshenziselwa ukuguqula indlela yokugeleza kwamanzi. Ehlelweni lwamanzi ahlinzekwa ngamapayipi ezakhiwo eziphakeme zokuhlala, ama-90 ℃ elbows ensimbi engenasici angamelana nengcindezi ethile yamanzi, futhi ngenxa yokumelana nayo okuhle kokugqwala, angaqinisekisa ukuvela okujwayelekile kohlelo olude, kunciphisa imvamisa yokulungiswa nokubuyiselwa.

Ukubuyekezwa Kwamakhasimende

Ukucaciswa kwe-ASTM A182 ukufakwa kwamapayipha kufaka ukufakwa okufakiwe, insimbi engenacala, i-alloy egoqiwe, i-allOy, amaphayiphu aphezulu kanye nenkonzo yokushisa ephezulu. Kamuva uthembisa ukuzokwenza nokusebenza okushisayo, bekuzokwehliswa phansi kumazinga athile ngaphambi kokwelashwa okushisa.