Ukunemba okuphezulu kokukhiqiza

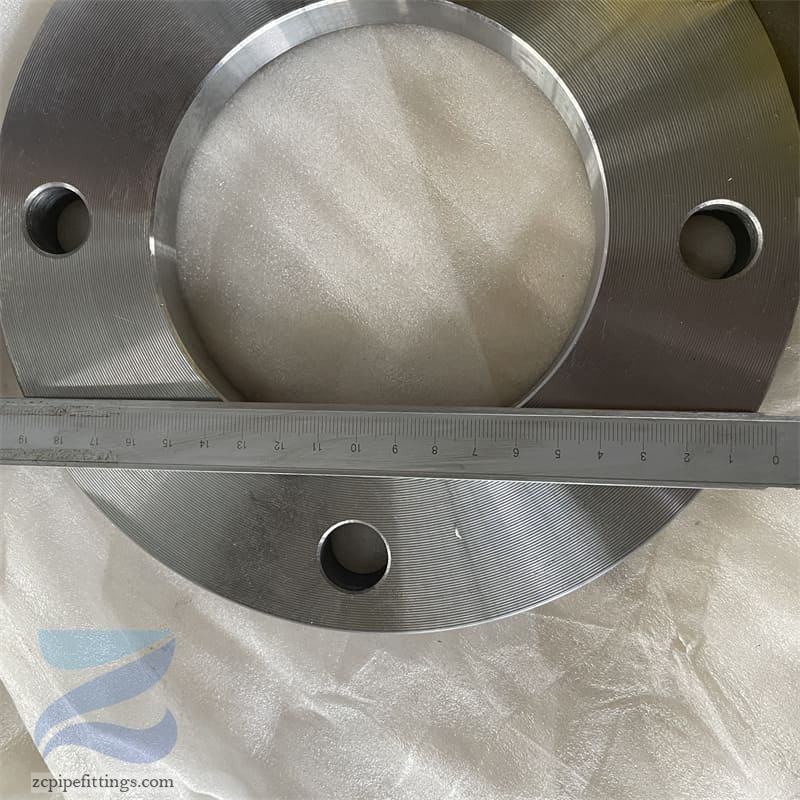

Le nyunyana yensimbi engenasici A182 yaziwa kakhulu ngokumelana kwayo kokushisa, amandla okushisa namandla ashubile. Imakwe kabusha futhi yaklanywa ukufeza izidingo zakho ezahlukahlukene zamapayipi, la mapayipi afaka ukumelana kahle nokuphikiswa ezinhlotsheni eziningi zezindawo zasemkhathini.

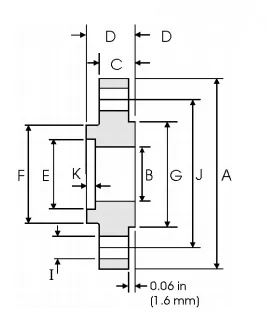

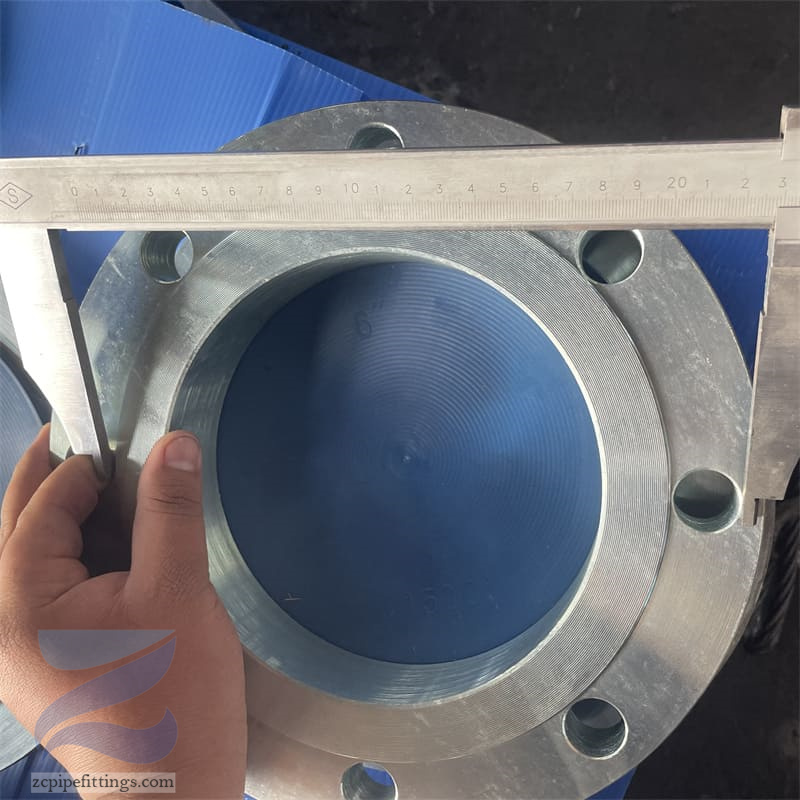

I-Duplex Steel Flainless Flange i-Flange eyenziwe ngensimbi engagqwali. Insimbi engagqwali isho esakhiweni esiqinile sokukhangela lapho isigaba se-Ferrite kanye nesigaba se-Auucen i-akhawunti ngayinye cishe ingxenye, nokuqukethwe okuthe xaxa kwesigaba ngokuvamile kudinga ukufinyelela ama-30%.

Ukufakwa kwentambo kwe-ASTM A1055 kuvame ukusetshenziswa kwe-Carbon Insimbi ebangeni elisetshenziselwa ukukhiqiza izingxenye zamapayipi ezinjengokugcwaliswa kwamapayipi amancane, ngokuvamile amapayipi amapayipi amancane, ngokuvamile amapayipi abuyisiwe

Le nyunyana yensimbi engenasici A182 yaziwa kakhulu ngokumelana kwayo kokushisa, amandla okushisa namandla ashubile. Imakwe kabusha futhi yaklanywa ukufeza izidingo zakho ezahlukahlukene zamapayipi, la mapayipi afaka ukumelana kahle nokuphikiswa ezinhlotsheni eziningi zezindawo zasemkhathini.