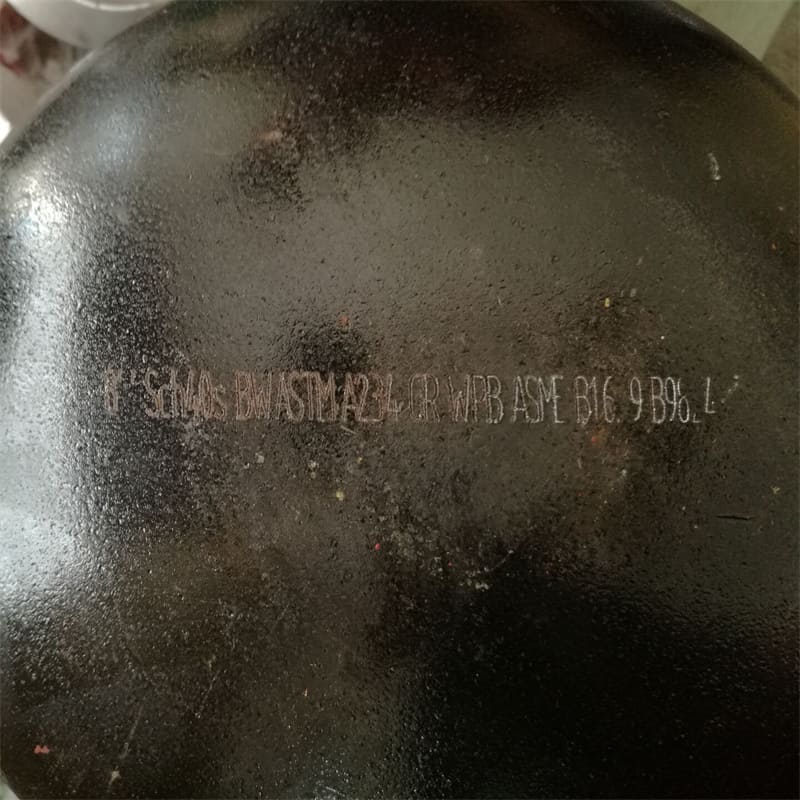

I-ASME B16.9 I-Steel Pear Cap

I-Carbon Iron Fittings Elbow inguhlobo oluvame kakhulu lwe-CS efanelekile esetshenziselwa ukujoyina ipayipi noma ishubhu ukuvumela ukuguqulwa kokuqondisa, imvamisa, ama-elbows angu-4 noma ama-exs angahle afakwe embhedeni we-butt welding,

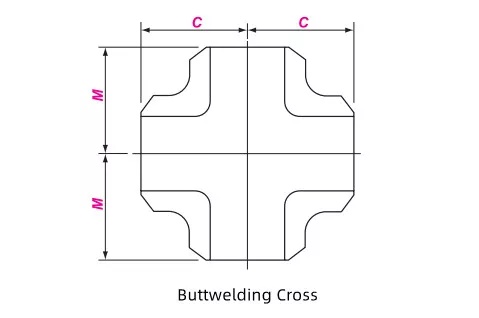

I-ASME B16.9 Isiphambano kufanelekile ipayipi ukuxhuma amapayipi amane ndawonye, futhi ukuxhumana kutholakala ngokushiswa. Idlala indima ekuhlanekezelweni noma ekuhlanganiseni ohlelweni lwepayipi futhi isixhumi esibalulekile ekwakhekeni kwamapayipi.

Isiphambano se-butt-weld sivame ukuba nezindawo ezine, kanti usayizi nokucaciswa kwalezi zinhlamvu kunqunywa ngokuya ngezidingo ezahlukahlukene zamapayipi. Isiteshi sangaphakathi senzelwe ngokufanelekile ukuqinisekisa ukuthi uketshezi lungageleza kahle esiphambanweni bese linciphisa ukulahleka kwengcindezi. Isibonelo, kwazinhlelo ezithile zepayipi ezimboni, izingxenye zeziphambano ze-butt-weld zingahle zicutshungulwe ngokusho kobubanzi obungaphandle kwepayipi, futhi izindawo zokuxhumana zizophathwa ngokukhethekile ukwenza imisebenzi ye-welding.