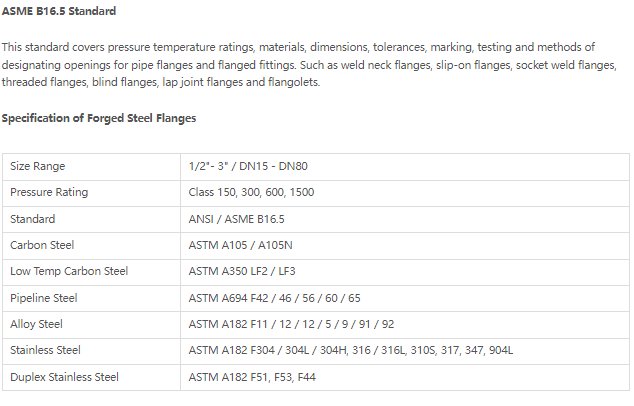

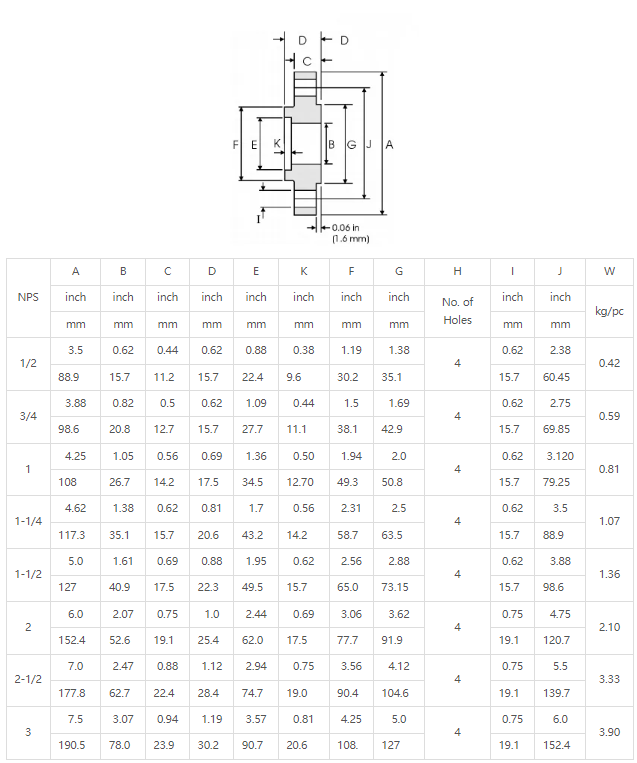

Socket Weld Flange Dimensions – Class 150 to Class 1500

This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

Socket weld flange simplified as SW flange, it has a recessed area (like a shoulder) in the flange bore, this shoulder serves as a guide to set the depth of the pipe that inserted to the flange. Socket welding flange initially designed for high pressure small diameters piping system.

Face: Raised face, Flat face, RTJ facing.

These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

Applications

- Water supply facilities

- Food industrial pipelines

- Chemical industrial pipelines

- Electronic industrial pipelines

- Air conditioning facility pipelines

- Agriculture and garden production transportation

- Pipeline network for solar energy facility