Ukusetshenziswa kwe-weld intamo flange

I-Finanliss yensimbi Flange iyathandwa ngoba insimbi engagqwali inezinhlobo ezinhle zokulwa ne-corlosive.Flang, SW, ama-Flanges asebenzisa ukuxhumeka okuhlukile ukuxhuma namapayipi.shang.

I-Finanliss yensimbi Flange iyathandwa ngoba insimbi engagqwali inezinhlobo ezinhle zokulwa ne-corlosive.Flang, SW, ama-Flanges asebenzisa ukuxhumeka okuhlukile ukuxhuma namapayipi.shang.

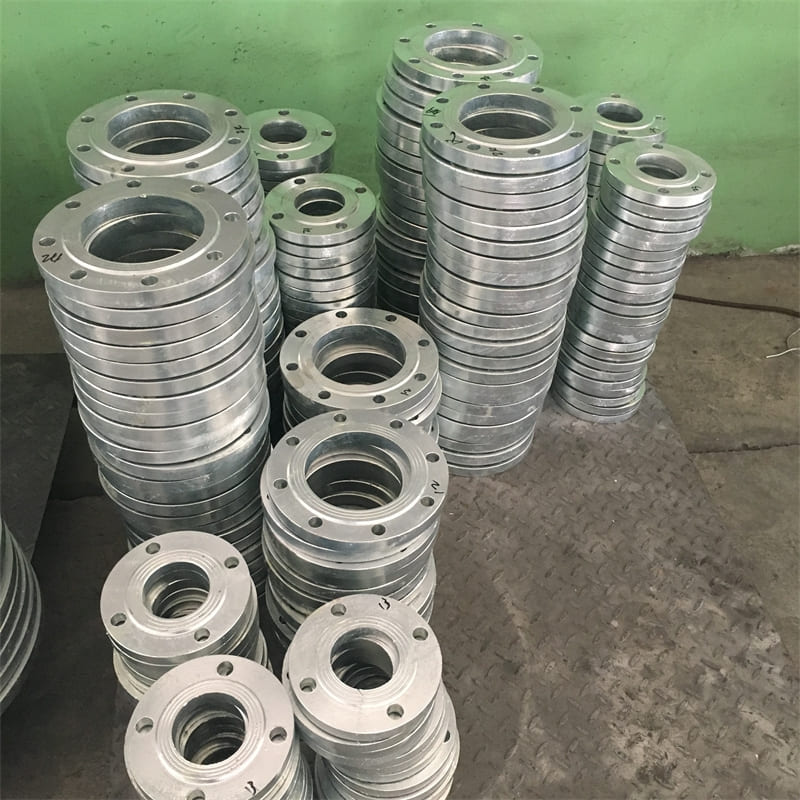

l. Ububanzi obukhulu be-welding flat bulding bunokufanelekela kancane kwengcindezi ephezulu uma kuqhathaniswa nomlingani wayo we-weld intamo. Isitayela esiyisisekelo sendandatho silungele isikhathi sokucindezela okuphansi. Isigaba se-Butt Weld se-Flange saziwa ngokuthi yi-weld intamo flange. Ifanela umcimbi wokushisa okuphezulu kanye nengcindezi njengoba kuchaziwe kwikhodi ye-ASME B16.47. Ama-Flanses amakhulu abuyimitha athandwa kakhulu futhi asetshenziswa embonini yezokuthutha indle, imboni yamandla omoya, imboni yamakhemikhali, kanye nemishini yemishini.

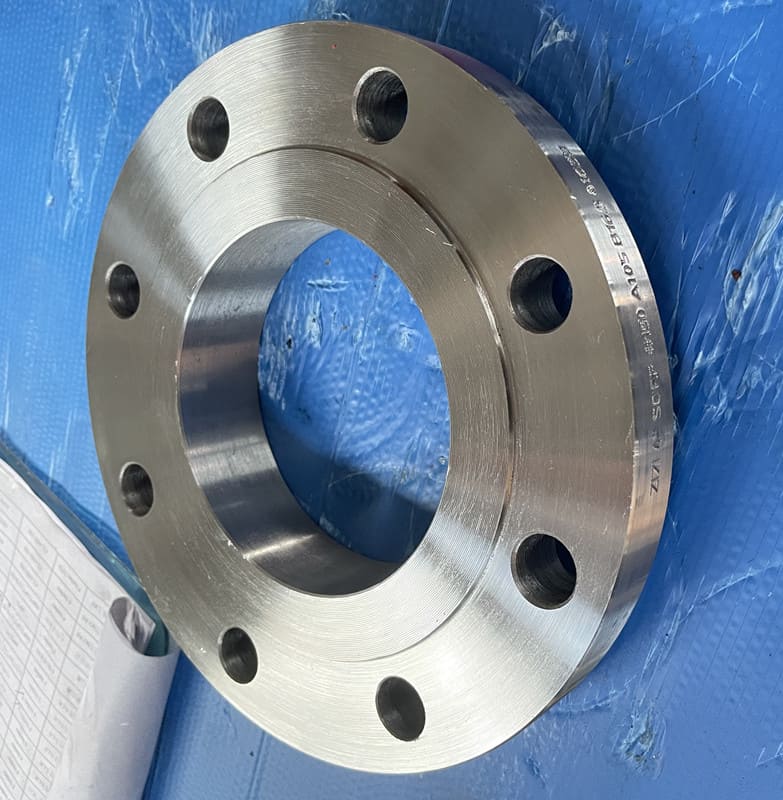

I-600LB Silp ku-Flange Engagqwali Flange

| Usayizi wesayizi | 304 I-Steel Fittings Fittings Kakhulu Usayizi Flanges |

| IHaiti Creole | 2 "wn flanges 1500lb SS A182 A350 |

| -Vamile | Kurdish (Kurmanji) |

| Insimbi yekhabhoni | Ukubuyekezwa Kwamakhasimende |

2 "wn flanges 1500lb SS A182 A350

I-Equal Tee ngohlobo olulodwa lokufakwa kwamapayipi, olubizwa nangokuthi iqonde i-tee eqondile okusho ukuthi ububanzi begatsha bufana nepayipi eliyinhloko (Run Pipe) ububanzi.

I-luster evamile egqamile

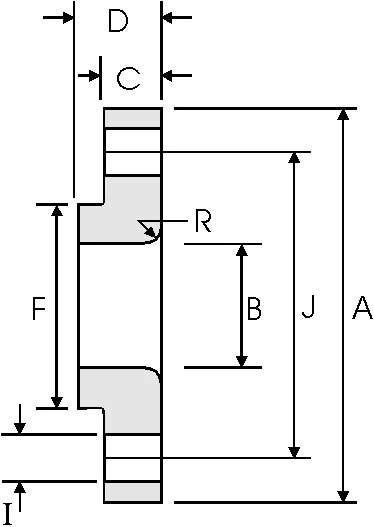

| I-Lap ehlanganisiwe i-Flange | Ngembaba | -Wokwanda | Indawo yangaphakathi | I-flange | -Wokwanda | Ithanga | Hub | Inani le | Bolt Hole | Ibanga elinquma phakathi ububanzi besingelezi | kg \ |

| Ibanga elinquma phakathi ububanzi besingelezi | Ibanga elinquma phakathi ububanzi besingelezi | Ibanga elinquma phakathi ububanzi besingelezi | Ukujiya | Ubude | Ithambo logalo elingaphandle kwengalo | Ibanga elinquma phakathi ububanzi besingelezi | Izimbobo | Ibanga elinquma phakathi ububanzi besingelezi | zombuthano | isiqephu | |

| uku | yezimbobo | ||||||||||

| phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | phakathi kwa- | |||

| m | m | m | m | m | m | m | m | m | |||

| 1/2 | 0.84 | 4.75 | 0.9 | 0.88 | 1.25 | 0.12 | 1.5 | 4 | 0.88 | 3.25 | 1.71 |

| 21.3 | 120.6 | 22.9 | 22.3 | 31.7 | 3 | 38.1 | 22.3 | 82.5 | |||

| 3/4 | 1.05 | 5.12 | 1.11 | 1 | 1.38 | 0.12 | 1.75 | 4 | 0.88 | 3.5 | 2.3 |

| 26.7 | 130 | 28.2 | 25.4 | 35 | 3 | 44.4 | 22.3 | 88.9 | |||

| 1 | 1.32 | 5.88 | 1.38 | 1.12 | 1.62 | 0.12 | 2.06 | 4 | 1 | 4 | 3.4 |

| 33.4 | 149.3 | 35.1 | 28.4 | 41.1 | 3 | 52.3 | 25.4 | 101.6 | |||

| 1 1/4 | 1.66 | 6.25 | 1.72 | 1.12 | 1.62 | 0.19 | 2.5 | 4 | 1 | 4.38 | 3.85 |

| 42.2 | 158.7 | 43.7 | 28.4 | 41.1 | 4.8 | 63.5 | 25.4 | 111.2 | |||

| 1 1/2 | 1.9 | 7 | 1.97 | 1.25 | 1.75 | 0.25 | 2.75 | 4 | 1.12 | 4.88 | 5.28 |

| 48.3 | 177.8 | 50 | 31.7 | 44.4 | 6.4 | 69.85 | 28.4 | 123.9 | |||

| 2 | 2.38 | 8.5 | 2.46 | 1.5 | 2.25 | 0.31 | 4.12 | 8 | 1 | 6.5 | 9.78 |

| 60.3 | 215.9 | 62.5 | 38.1 | 57.15 | 7.9 | 104.6 | 25.4 | 165. 1 | |||

| 2 1/2 | 2.88 | 9.62 | 2.97 | 1.62 | 2.5 | 0.31 | 4.88 | 8 | 1.12 | 7.5 | 13.6 |

| 73 | 244.3 | 75.4 | 41.1 | 63.5 | 7.9 | 123.9 | 28.4 | 190.5 | |||

| 3 | 3.5 | 9.5 | 3.6 | 1.5 | 2. 120 | 0.38 | 5 | 8 | 1 | 7.5 | 11.3 |

| 88.9 | 241.3 | 91.4 | 38.1 | 53.8 | 9.7 | 127 | 25.4 | 190.5 | |||

| 4 | 4.5 | 11.5 | 4.6 | 1.75 | 2.75 | 0.44 | 6.25 | 8 | 1.25 | 9.25 | 19.2 |

| 114.3 | 292.1 | 116.8 | 44.4 | 69.85 | 11.2 | 158.7 | 31.7 | 234.9 | |||

| 5 | 5.56 | 13.75 | 5.69 | 2 | 3. 120 | 0.44 | 7.5 | 8 | 1.38 | 11 | 31.2 |

| 141.3 | 349.2 | 114.5 | 50.8 | 79.25 | 11.2 | 190.5 | 35 | 279.4 | |||

| 6 | 6.63 | 15 | 6.75 | 2.19 | 3.38 | 0.5 | 9.25 | 12 | 1.25 | 12.5 | 40.5 |

| 168.3 | 381 | 171.5 | 55.6 | 85.8 | 12.7 | 234.9 | 31.7 | 317.5 | |||

| 8 | 8.63 | 18.5 | 8.75 | 2.5 | 4.5 | 0.5 | 11.75 | 12 | 1.5 | 15.5 | 71.5 |

| 219.1 | 469.9 | 222.3 | 63.5 | 114.3 | 12.7 | 298.4 | 38.1 | 393.7 | |||

| 10 | 10.75 | 21.5 | 10.92 | 2.75 | 5 | 0.5 | 14.5 | 16 | 1.5 | 18.5 | 104 |

| 273 | 546.1 | 277.4 | 69.85 | 127 | 12.7 | 368.3 | 38.1 | 469.9 | |||

| 12 | 12.75 | 24 | 12.92 | 3.12 | 5.62 | 0.5 | 16.5 | 20 | 1.5 | 21 | 139 |

| 323.8 | 609.6 | 328.2 | 79.25 | 142.7 | 12.7 | 419.1 | 38.1 | 533.4 | |||

| 14 | 14 | 25.25 | 14.18 | 3.38 | 6. 120 | 0.5 | 17.75 | 20 | 1.62 | 22 | 161 |

| 355.6 | 641.3 | 360.2 | 85.8 | 155.4 | 12.7 | 450.8 | 41.1 | 558.8 | |||

| 16 | 16 | 27.75 | 16.19 | 3.5 | 6.5 | 0.5 | 20 | 20 | 1.75 | 24.25 | 194 |

| 406.4 | 704.8 | 411.2 | 88.9 | 165.1 | 12.7 | 508 | 44.4 | 615.9 | |||

| 18 | 18 | 31 | 18.2 | 4 | 7.5 | 0.5 | 22.25 | 20 | 2 | 27 | 267 |

| 457.2 | 787.4 | 462.3 | 101.6 | 190.5 | 12.7 | 565.1 | 50.8 | 685.8 | |||

| 20 | 20 | 33.75 | 20.25 | 4.25 | 8.25 | 0.5 | 24.5 | 20 | 2.12 | 29.5 | 334 |

| 508 | 857.2 | 514.4 | 107.9 | 209.5 | 12.7 | 622.3 | 53.8 | 749.3 | |||

| 24 | 24 | 41 | 24.25 | 50.5 | 10.5 | 0.5 | 29.5 | 20 | 2.62 | 35.5 | 618 |

| 609.6 | 1041.4 | 616 | 139.7 | 266.7 | 12.7 | 749.3 | 66.55 | 901.7 |

KanjaniMinadCawuhlana ngomuthiUshikukaziisicwayiziI-lap ngokuhlangene E fhlala

Okokuqala, hlela i-Carbon Insimbi ye-Lap ehlanganisiwe nge-flange yepayipi noma eminye imishini, futhi uqinisekise ukuthi izimbobo nezimbobo ze-bolt zama-flanges amabili ziqondaniswe. Faka i-gasket efanelekile phakathi kwama-flangese. Izinto ezibonakalayo nobukhulu be-gasket kufanele kukhethwe ngokuya ngemibandela efana namaphakathi, lokushisa nengcindezi. I-gasket kufanele ibekwe endaweni yokubopha uphawu futhi iqinisekise ukuthi iyisicaba futhi ingenamikhawulo. Ekugcineni, faka ama-bolts kwizimbobo ze-bolt ze-flange ngamunye, unaka indlela kanye nesikhundla samabhodlela ukuze uqinisekise ukuthi ama-bolts angaqiniswa kahle. Sebenzisa amathuluzi anjengemishini yokuqinisa ama-bolts ekuqaleni, futhi uqaphele ukufaka amandla ngokulinganayo ukugwema ingxenye yokuqiniseka noma ngokweqile. Ngemuva kokuqinisekisa ukuthi isikhundla silungile, sebenzisa amathuluzi anjengemishini yokuqinisa ama-bolts wesikhathi sokugcina.