ASME B16.9 6IN SCH80 Butt Weld Tee Pipe Fittings

Steel tee is a T-shaped pipe fittings that has three branches, normally has two forms with Equal Tee and Reducing Tee, both are used to divide the pipelines to adjust the flow rate and change the direction.

ASME B16.9 6IN SCH80 Butt Weld Tee Pipe Fittings is a T-shaped pipe fittings that has three branches, normally has two forms with Equal Tee and Reducing Tee, both are used to divide the pipelines to adjust the flow rate and change the direction.Since the distance between the branch pipe and the pipe run is the same, an equivalent tee is used. It is used to handle any high or low weight fluid flow through the tee.Reducing tee is a kind of pipe fitting whose branch size is smaller than the size of pipeline parts. It is used for main pipe string accessories, solvent welding accessories, side outlet and conflicting soluble welding accessories. Such fittings are important because they meet two needs, that is, to connect or separate liquid streams. They are widely used in positive and vacuum applications.

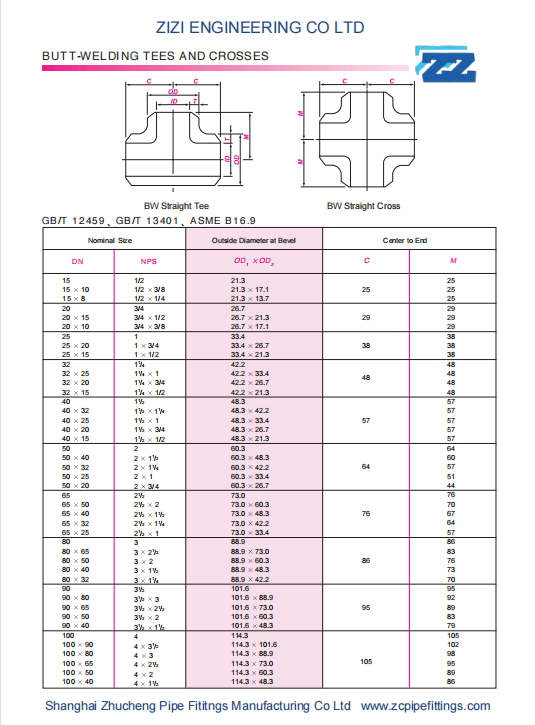

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

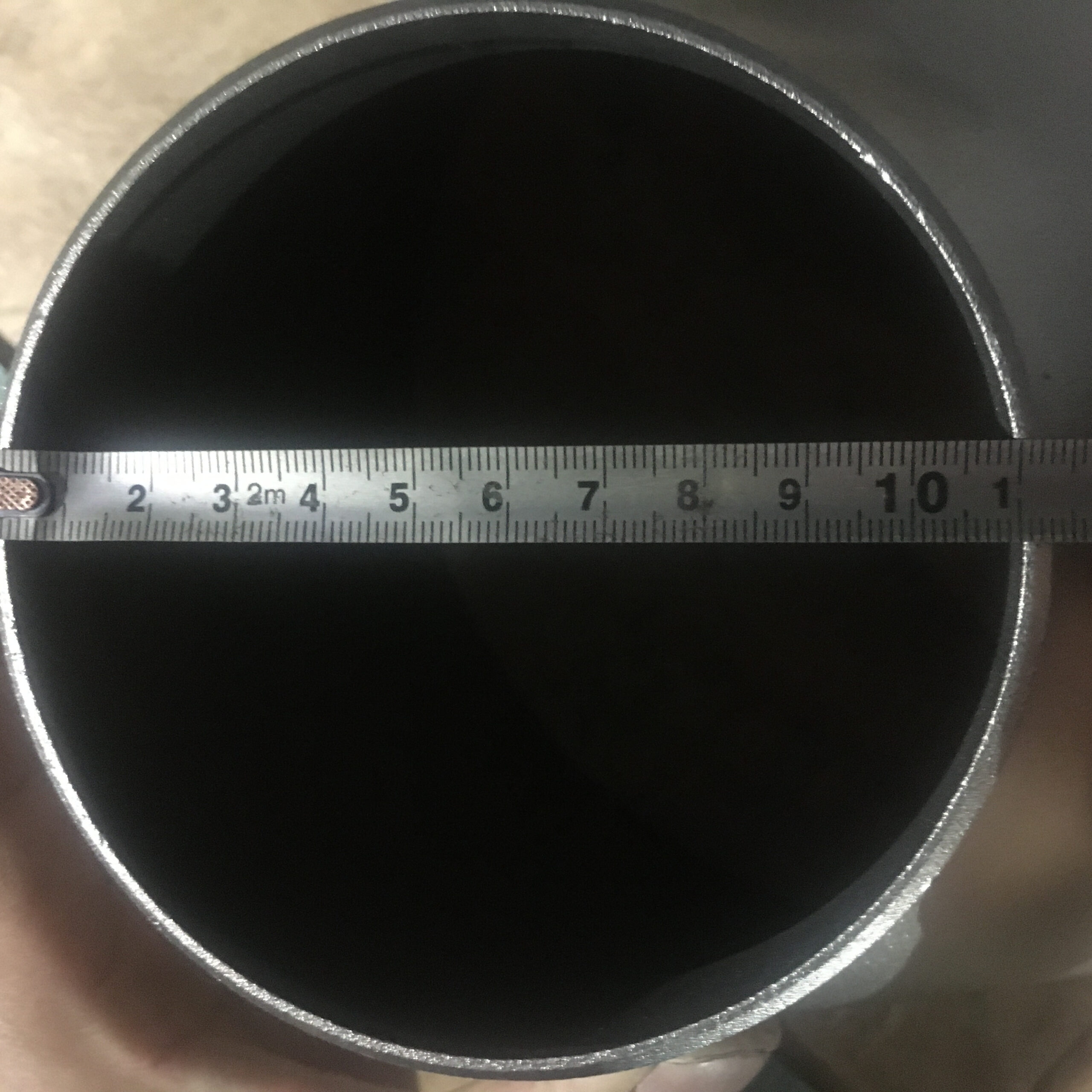

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

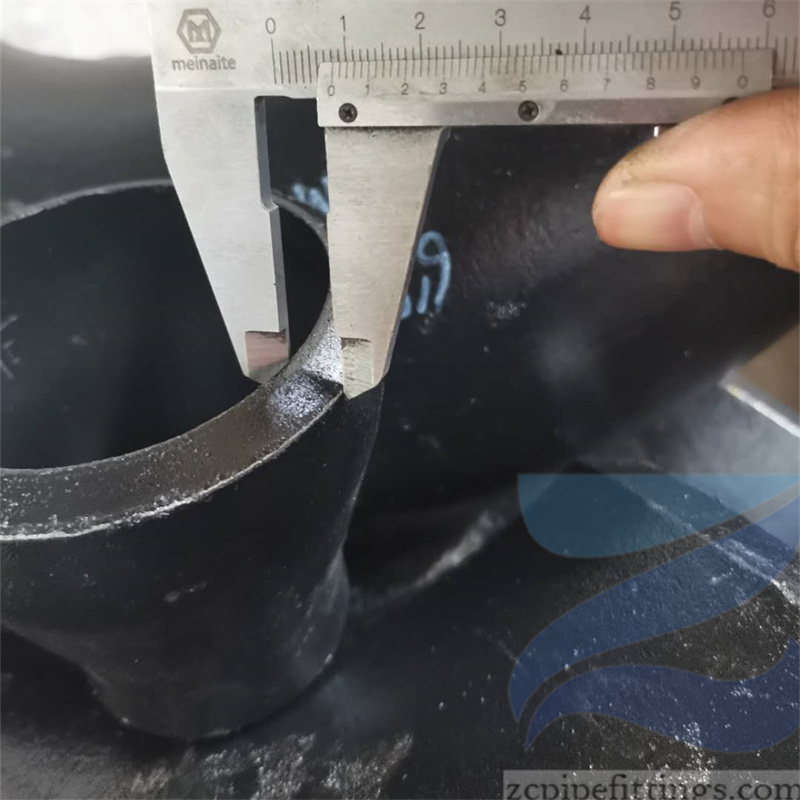

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Product features

- Good general corrosion resistance and high strength

- Good sulfide stress corrosion resistance

- Resistance to chloride pitting and crevice corrosion

- Higher resistance to chloride stress corrosion cracking

- Easy to weld and conform

Equal Tee VS Reducing Tee

- Steel Equal Tee pipe fittings: The three branches of tee have same diameters.

- Steel Reducing Tee: The branch diameter is smaller than the main line diameter. Tee reducer is usually described as NPS diameters in 4”x 4”x 3”, 4”is the main line pipe diameter, and 3”is the reducing branch.

Applications

Oil and gas transmissions

Petroleum and Oil refining

Water treatment systems

Chemical Industries