ASTM A234 WPB BUTT WELDING PIPE FITTING 90 DEGREE LR ELBOW ASME B 16.9 MSS SP43

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

What is LR 90 elbow?

Long Radius 90° Elbows make a 90 degree change of direction in the run of the pipe. The radius of the bend in this elbow is “long radius”, or in other words, greater than that of the nominal size.A 90° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange.

Cerification of LR 90 elbow

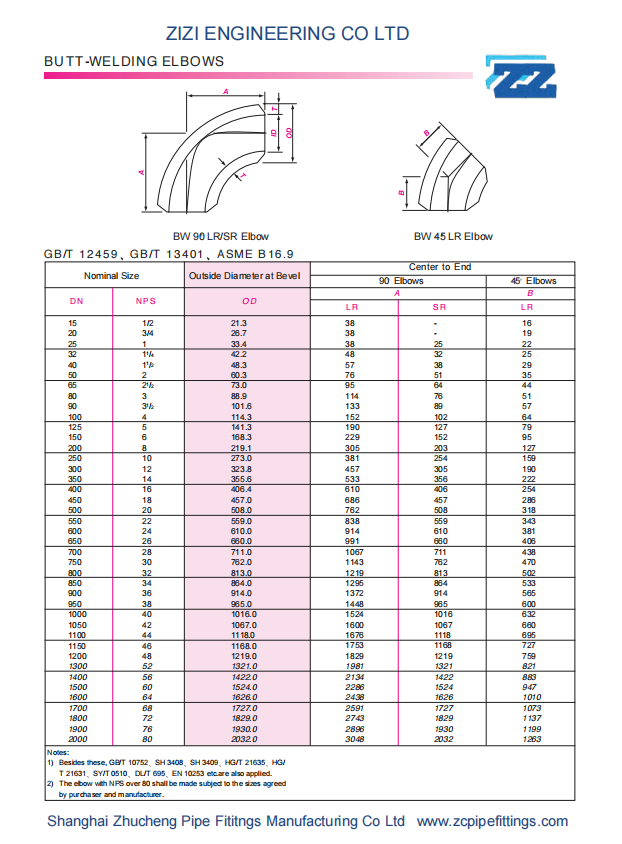

| Size Range | 1/2″-80″/DN15-DN2000 |

| Thickness Schedule | SCH10-SCH160,XSX |

| China Standard | GB/T12459,GB/T13401,HG/T21635/21631,SH348/3409 |

| America Standard | ANSI/ASME B 16.9/MSS SP43 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235,20#,35#,45#,20G,ASTM A234 WPB/WPC |

| Low Tem Carbon Steel | Q345B,16Mn,ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42/46/46/60/65 |

| Alloy Steel | ASTM A234 WP11/WP12/WP5/WP9/WP91/WP92,15CrMoG |

| Stinless Steel | ASTM A403 WP304/304L/304H,316,316L,310S,317,347,904L |

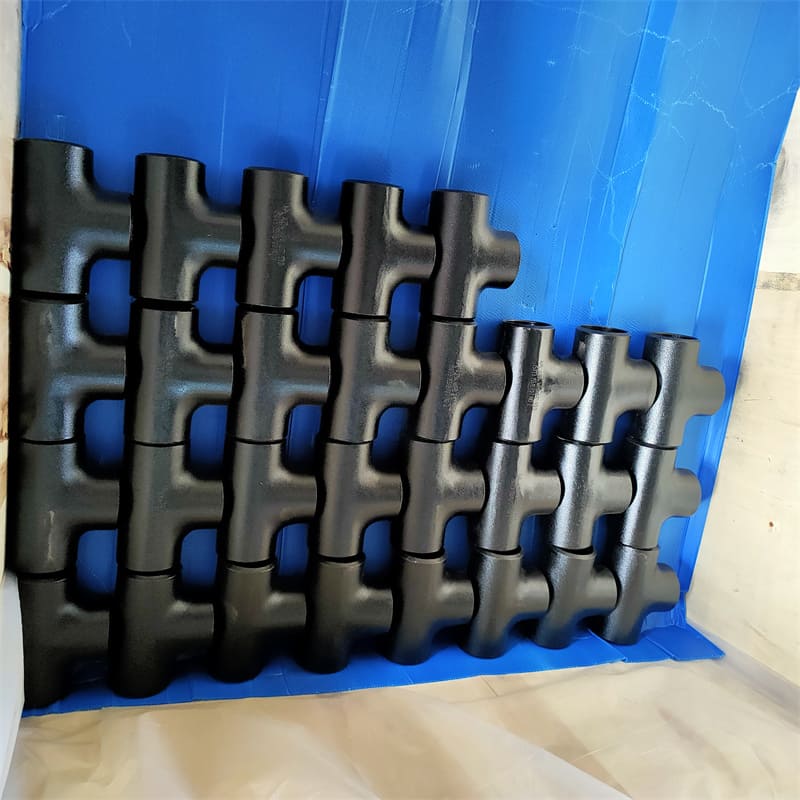

Advantagaes of Butt welding elbows

Butt weld elbow is a steel elbow formed by hot pressing or forging. Its connection form is to directly weld the elbow and steel pipe. Butt welded elbows are mainly used for elbow with higher pressure and temperature than other connection types (socket welded elbow or threaded pipe elbow)