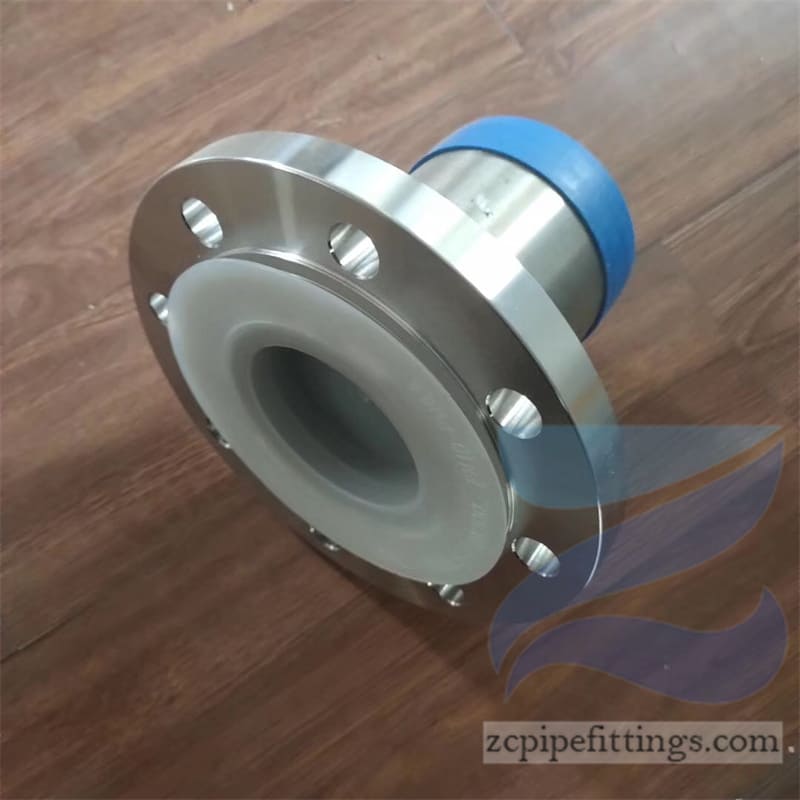

High Pressure 2IN 1500PSI Socket Weld Flange

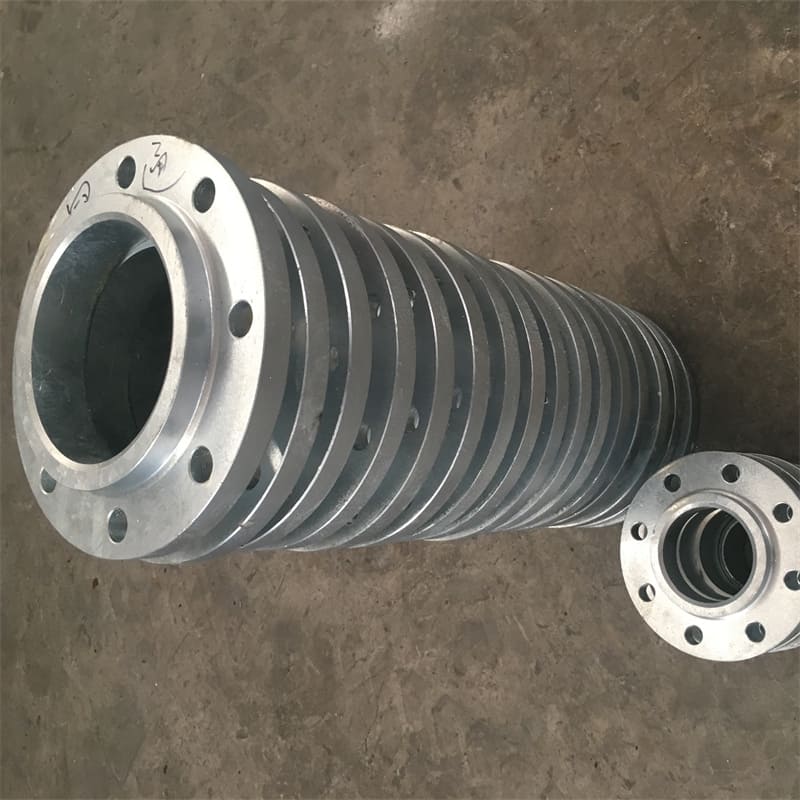

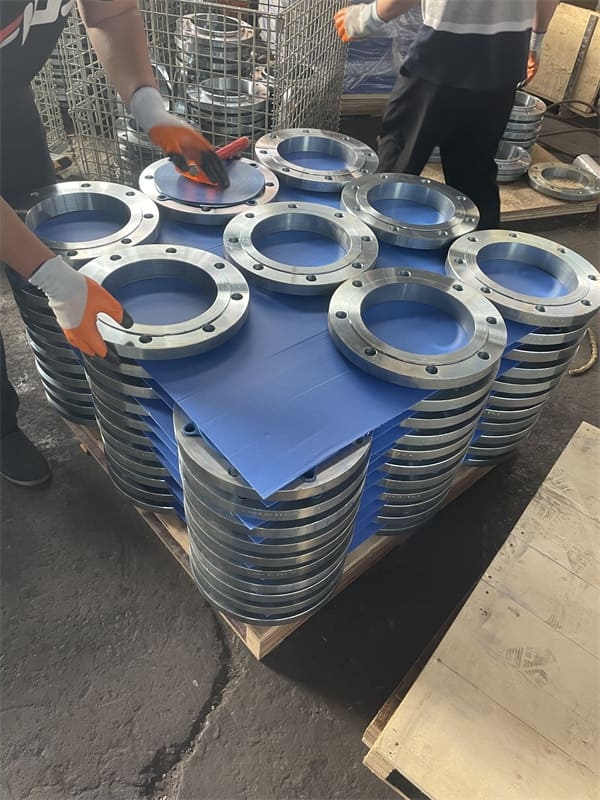

orged steel flange is a disc-shaped piece of equipment used to connect a pipe to fittings or valve or other component to form a pipework system. Usually flange has been attached to pipe or tube end to, and then a gasket is inserted in the middle to form a seal. Finally they are joined together with bolts and nuts.

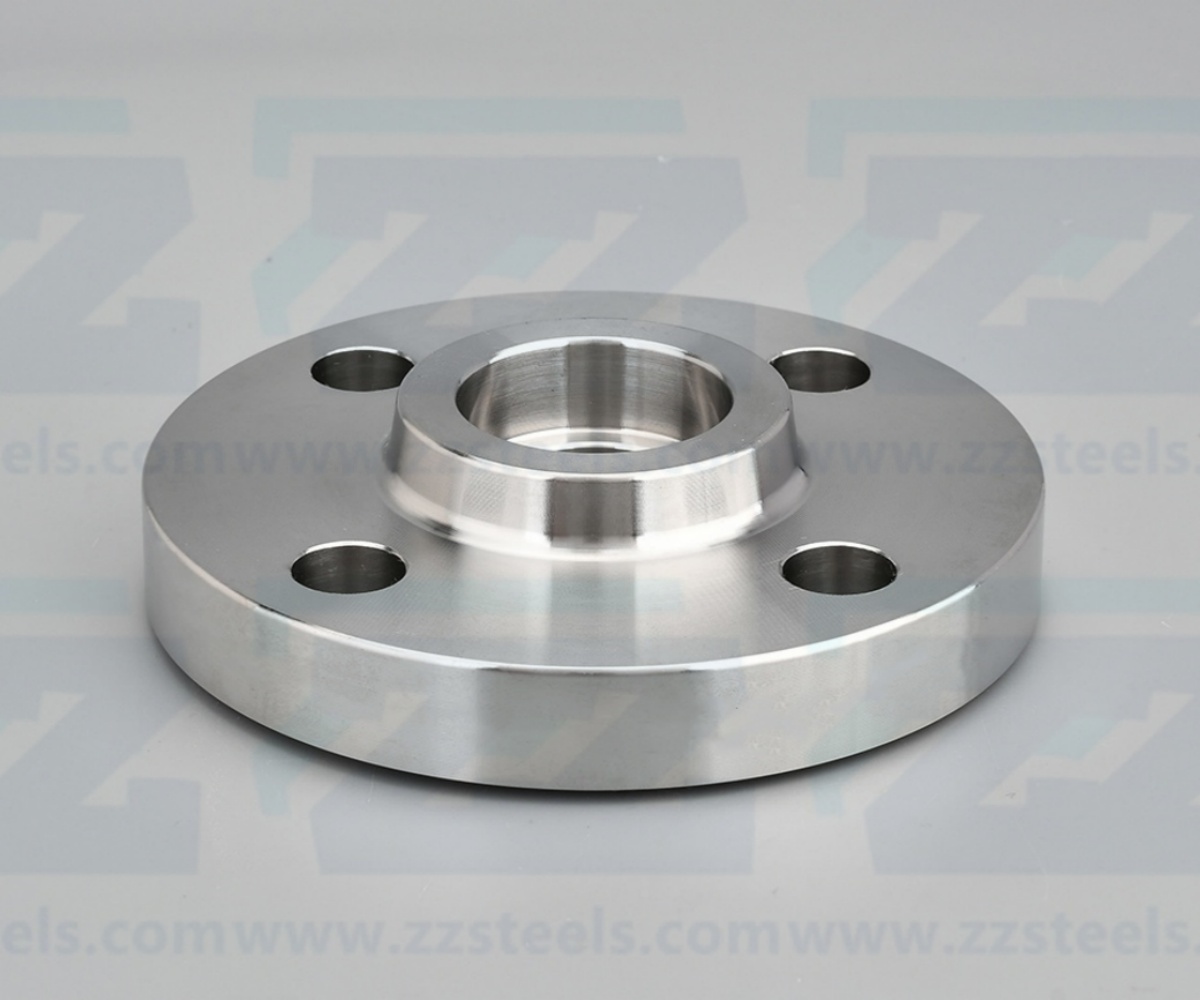

Socket weld flanges are a less common but equally effective connection for flanges which require less overall available space than a traditional weld neck flange, with a counterbore in the center to allow for a clean weld of pipe into the socket. Usually furnished in smaller nominal pipe sizes, these make an excellent alternative to weld necks and slip ons when necessary. An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

| Shape | Weld Neck Flange ( WN),Slip-on Flange (SO), Threaded Flange (THD),Socket Weld Flange (SW),Blind Flange (BL),Lap Joint Flange (LAPJ),Plate flange (PL) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

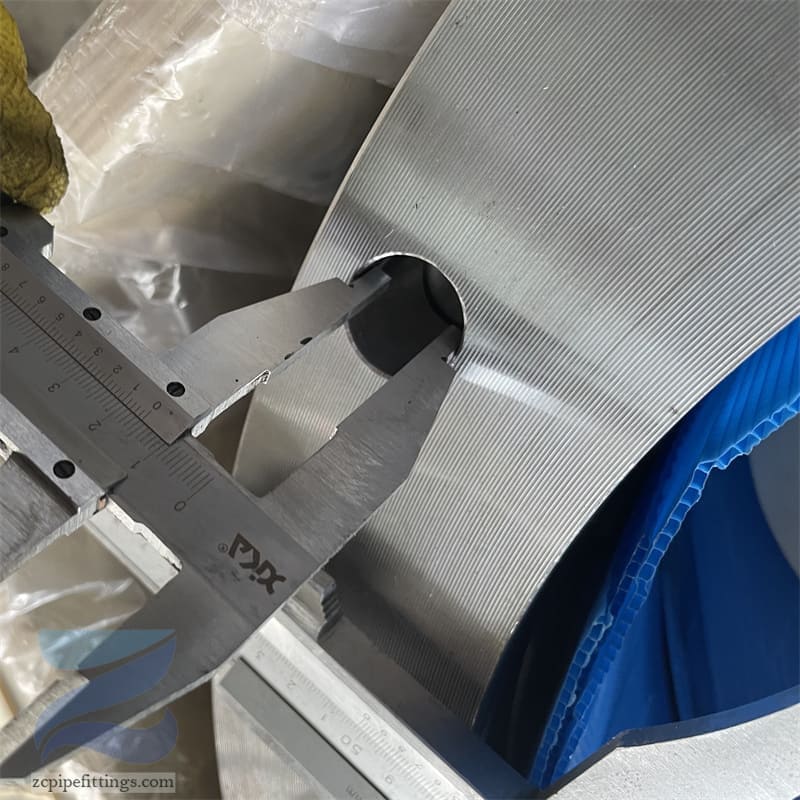

These socket flanges connect to square end pipe with a fillet weld at the ID of the hub of the socket, as the pipe is designed to sit almost flush against the counter bore of the flange. The expansion gap between the end of the pipe and the counter bore leaves just enough space for the welder to adjust the pipe within the connection. It is important to note that a butt weld pipe connection is not recommended for suiting to a socket counter bore connection when a square end pipe connection is possible.

Class 150 lb Socket Weld Flange Dimensions & Weight

Class 300 lb Socket Weld Flange Dimensions & Weight

Notes

1) Dimension B corresponds to the pipe inside diameter. Values quoted assume 40S/Standard wall thickness.

2) Weights are based on manufacturer’s data and are approximate.

Class 600 lb Socket Weld Flange Dimensions & Weight

Class 1500 lb Socket Weld Flange Dimensions & Weight

Notes

1) Class 400 socket weld flanges may be provided in NPS 1/2 to 2-1/2 using Class 600 dimensions.

2) Dimension B corresponds to the pipe inside diameter. Values quoted assume 40S/Standard wall thickness .

3) Weights are based on manufacturer’s data and are approximate.

4) The blank space needs o be specified by purchaser.

A

A