Home » Forged Steel Fittings » Stainless Steel ASTM A182F304L Thread Cap Dimensions

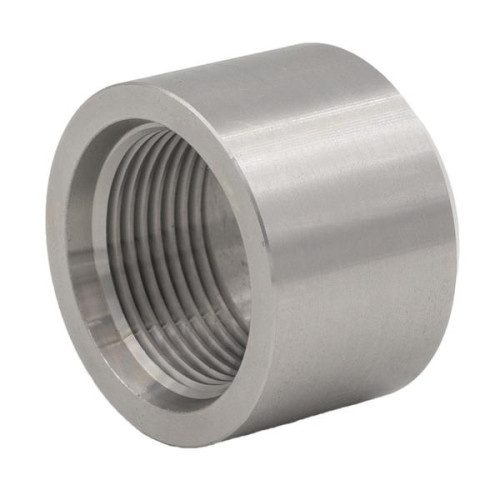

Stainless Steel ASTM A182F304L Thread Cap Dimensions

The use of Forged End Pipe Caps is common in many industries such as oil and gas industries, chemical industries and water supply lines.

Contact US

Get Price

Share:

Content

Production Description

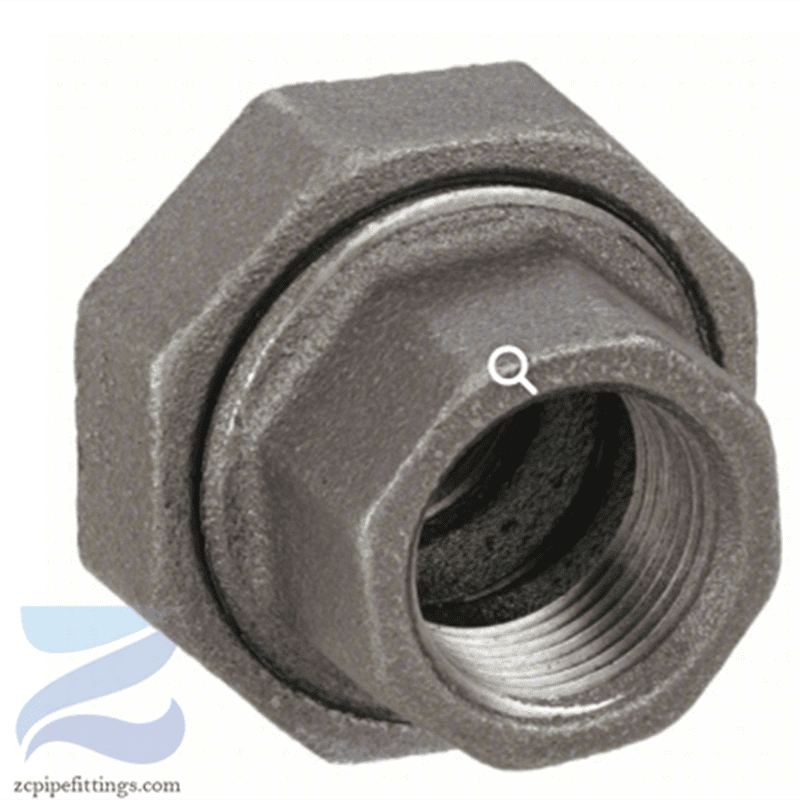

Stainless Steel ASTM A182F304L Thread Cap Dimensions has the same function as the pipe plug and is used to close the pipe. It is similar to the blind plate in form, but the blind plate can be moved and removed, while the pipe cap cannot be removed. The use of Forged End Pipe Caps is common in many industries such as oil and gas industries, chemical industries and water supply lines.

Thread Types:

NPT PT BSPP BSPT PF

Product features

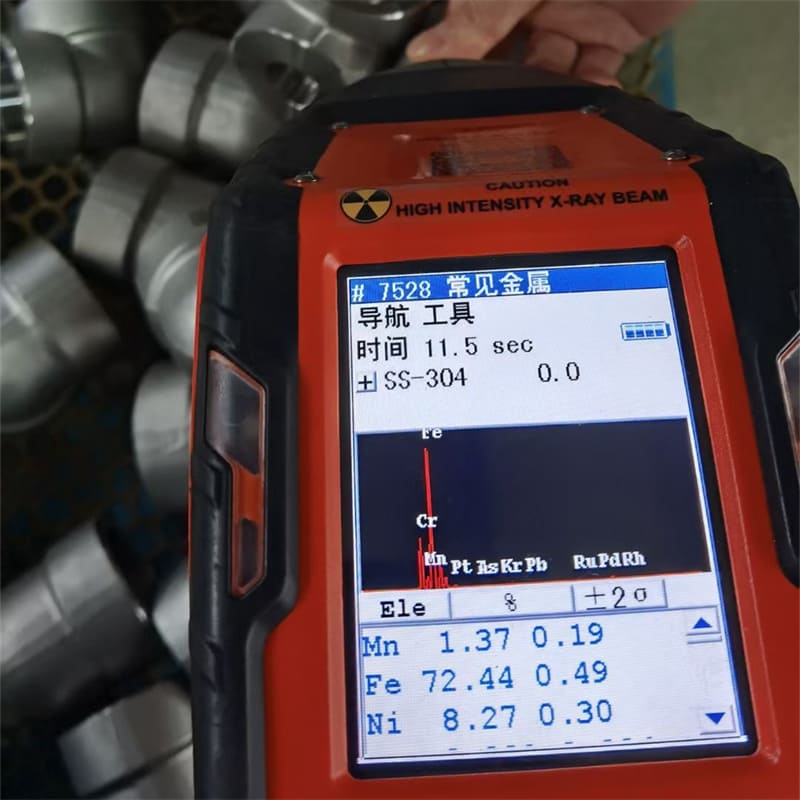

- Corrosion resistance, wear resistance and high hardness.

- The structure is tight, intact and the pores are small.

- It has strong separation from the base metal and good adhesion.

- It is evenly distributed and has a certain thickness.

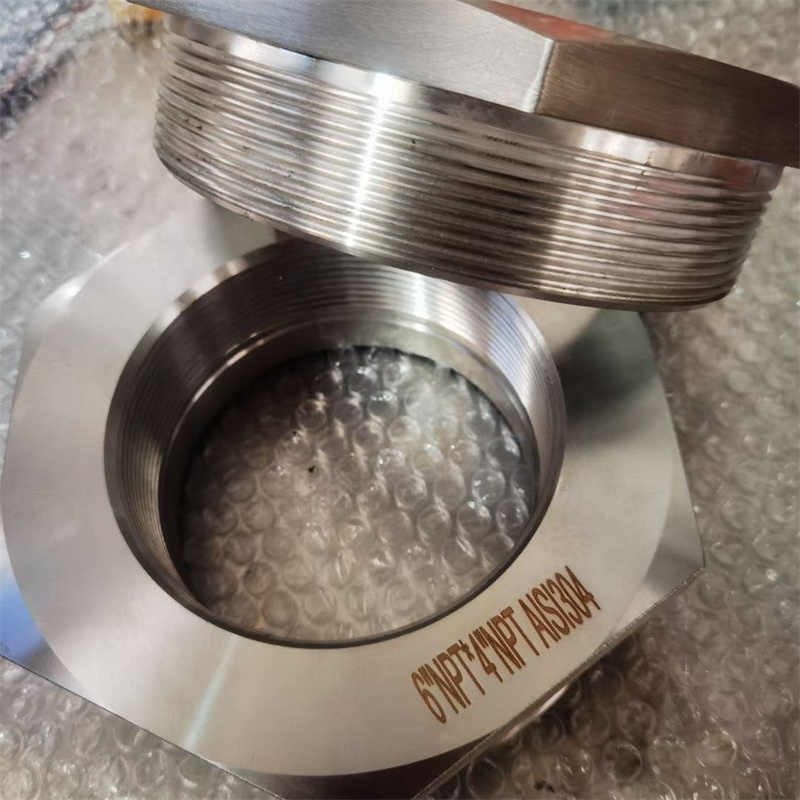

Specificaton of Stainless Steel ASTM A182F304L Thread Cap Dimensions

| Threaded Pipe Fittings Specification | |

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Threaded Cap for Pipe Dimensions

Inquiry

More Threaded Pipe Fitings