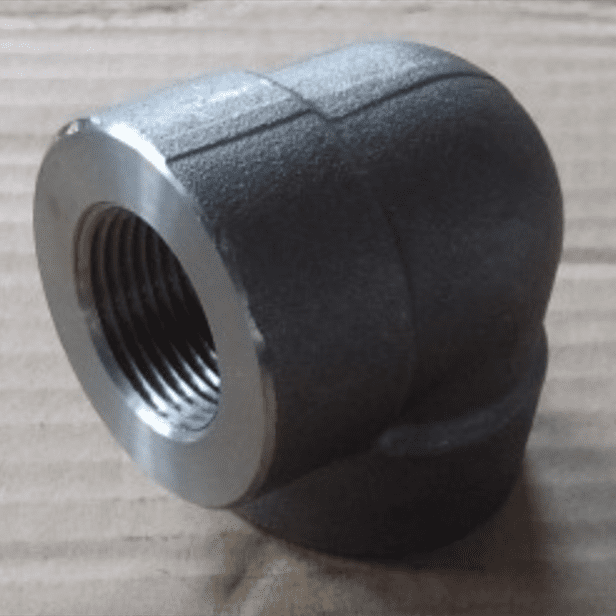

A182 F321 B16.11 Threaded Steel Pipe Fittings Coupling

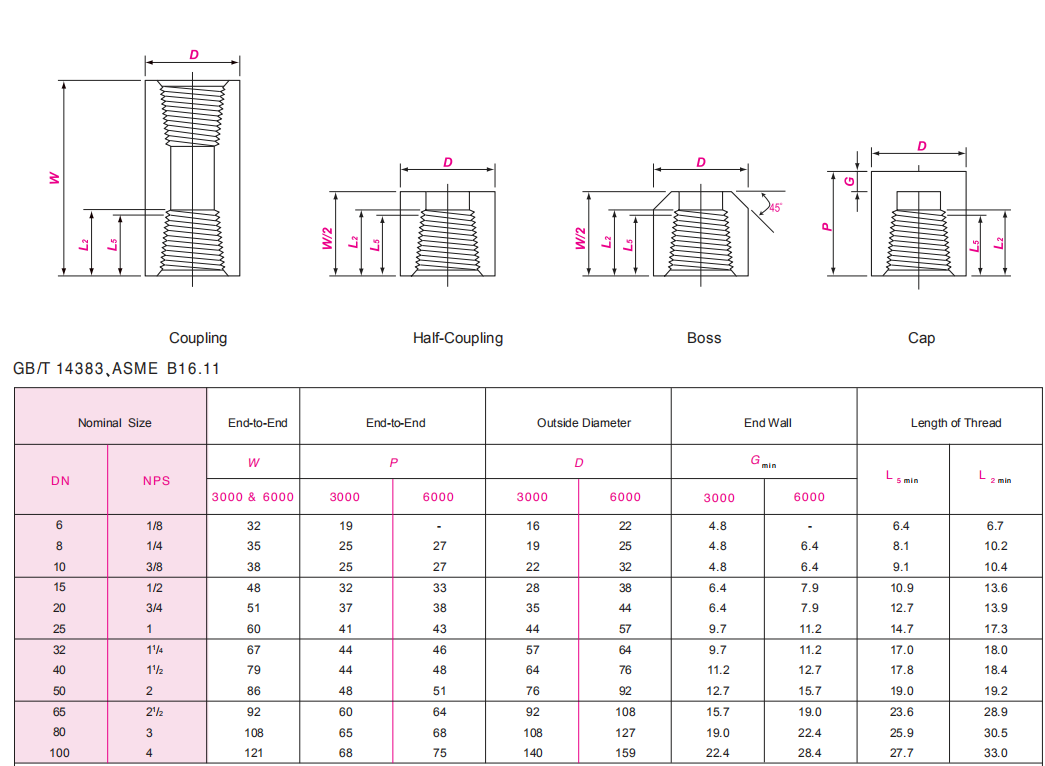

ASME B16.11 is the standard of both socket-welding and threaded. Threaded fittings are available in pressure ratings Class 2000, 3000, and 6000;

Socket welding fittings are available in pressure ratings Class 3000, 6000, and 9000.

A182 F321 is the grade of Stainless Steel Threaded Steel Pipe Fittings Coupling.

ASME B16.11 is the standard contains ratings, dimensions, tolerances, marking and material requirements for forged fittings, both socket-welding and threaded. Threaded fittings are available in pressure ratings Class 2000, 3000, and 6000;

Socket welding fittings are available in pressure ratings Class 3000, 6000, and 9000.

Generally, both fittings size range is 1/8″- 4″or DN6-DN100.

There are various types of ASME B16.11 socket-welding fittings, such as Elbow, Cross, Tee, Coupling, Half Coupling, Boss, Cap, Union and Sockolet; while ASME B16.11 threaded fittings can be furnished in product forms of Elbow, Cross, Tee, Coupling, Half Coupling, Boss, Cap, plug and bushing.

Stainless Steel Pipe Fittings are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

Threaded pipe fittings provide permanent welded connections for pipes. Threaded joints probably represent the oldest method of joining piping systems. Same as Socket Weld fittings, threaded fittings are mainly used for small pipe diameters (Small Bore Piping); generally, for piping whose nominal diameter is NPS 2 or smaller.

They are available in three pressure ratings: 2000lbs, 3000lbs and 6000lbs.

Threaded Steel Coupling is a short piece with screw in NPT or BSP ends or one end, which is available in stainless steel, alloy steel and carbon steel. The size range is DN6-DN100. There are various grade of A694 Threaded Coupling, Such as A694 F42 / 46 / 52 / 56 / 65 / 70

Forged threaded pipe fittings are named by its manufacturing forging process and produced according to ASME B16.11, MSS-SP-79\83\95\97 and BS3799 standards. It is a connector in between nominal bore pipes. Their material can be made of carbon steel A105 and stainless steel SS316 & 304. Threaded fittings are mainly used for small pipe diameters, generally for piping whose nominal diameter is NPS 2 or smaller. Threaded joints probably represent the oldest method of joining piping systems.

| Threaded Pipe Fittings Specification | |

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

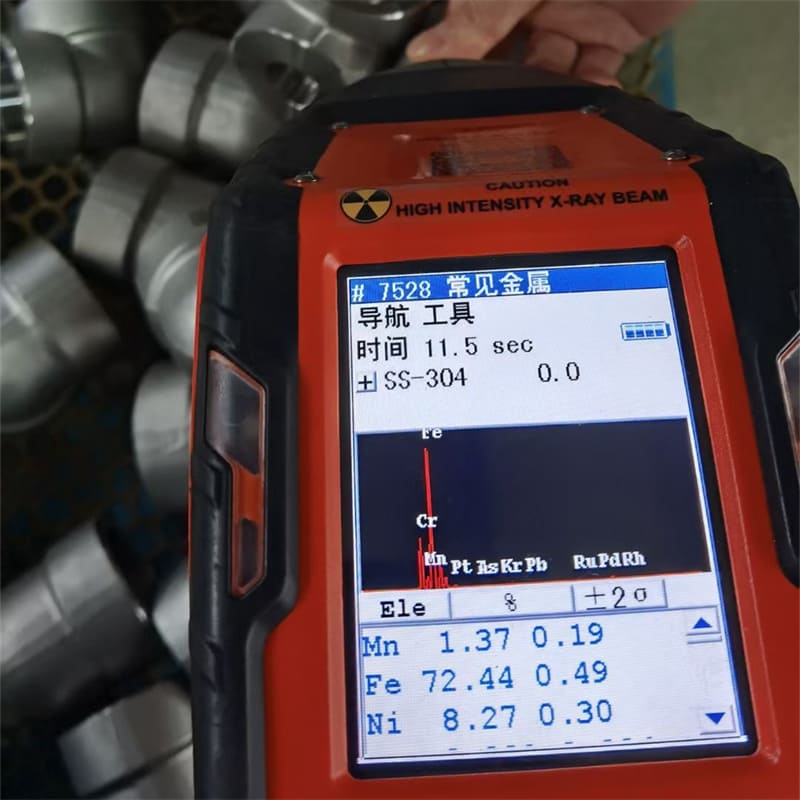

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Threaded Coupling Drawing and Dimension

Application of Threaded Pipe Fittings

Oil and Gas

Chemical

Water Pipeline

Noncritical Applications

Power station

Fire Protection