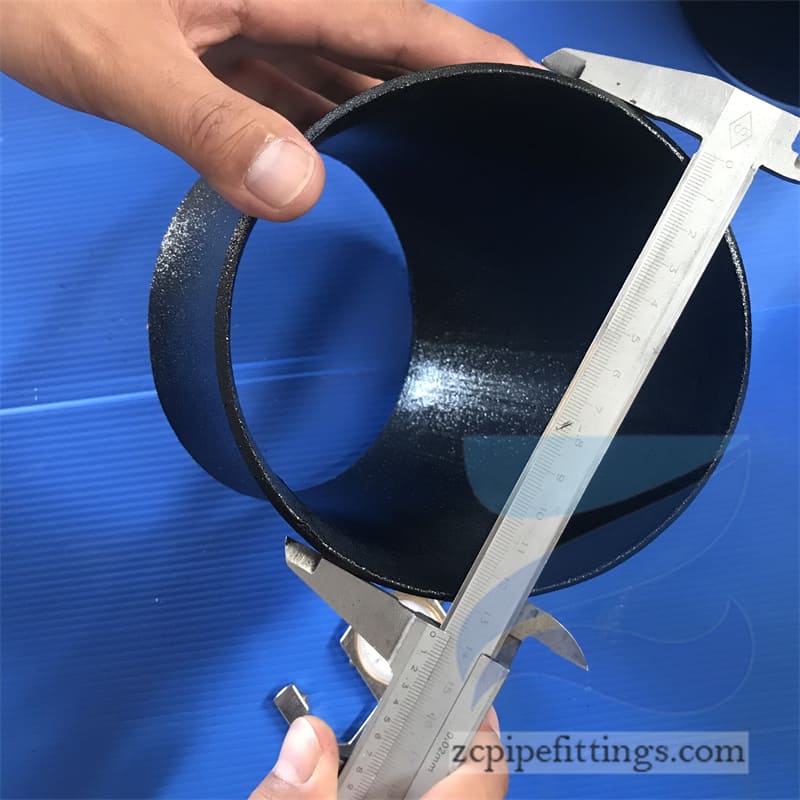

Carbon Steel A234WPB Butt Weld Reducer Dimensions

Concentric reducer is used to join pipe sections or tube sections on the same axis. It is cone-shaped, and is used when there is a shift in diameter between pipes. A pipe reducer is available in various specifications, such as a single diameter change and also in a multiple diameter change.

Production Description

Carbon Steel A234WPB Butt Weld Reducer Dimensions is used to join pipe sections or tube sections on the same axis. It is cone-shaped, and is used when there is a shift in diameter between pipes. A pipe reducer is available in various specifications, such as a single diameter change and also in a multiple diameter change. The pipes cannot appreciate because of what the external arrangement of the pipe reducer seems but the flow of the pipe is changed by the internal width conical transition arrangement. It can be axially shifted and externally reconfigured to offer more efficient reducer connection. Concentric reducers facilitate the delivery of mud and abrasive fluids and are suitable for corrosive operations and where different ratings and wear protection are required between flanges.

Product features

- Concentric reducers will change kindly between the pump and piping.

- Concentric reducers are tapered and are used when the diameter between pipes changes.

- Concentric reducers provide an in-line conical transition between pressurized pipes of different diameters.

- The length dimension of the reducer is almost equal to the average of the big bore and smaller bore pipe diameters.

Specificaton of ASTM A403WP 316L 2”x11/2” SCH40S Concentric Reducer

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Concentric Reducer Dimensions & Sch 40 Weight