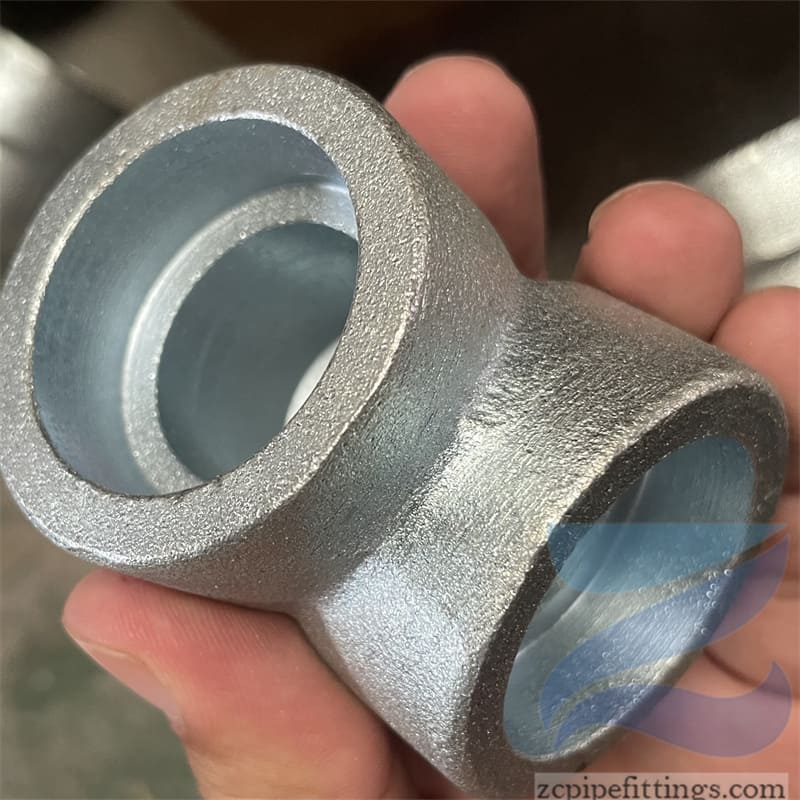

Galvanized 6000# 90DEG Socket Weld Elbow

The socket weld elbow is resistance corrosion/pitting/oxidation/stress corrosion cracking and crevice corrosion. Reducing elbows connect two pipes of different diameters to reduce the diameter when the pipe rotates.

A Socket Weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. To join pipe to Valves and fittings or to other sections of pipe, fillet-type seal welds be used. Socket Welded Joints construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations. Fatigue resistance is lower than that in butt-welded construction due to the use of fillet welds and abrupt fitting geometry, but it is still better than that of most mechanical joining methods.

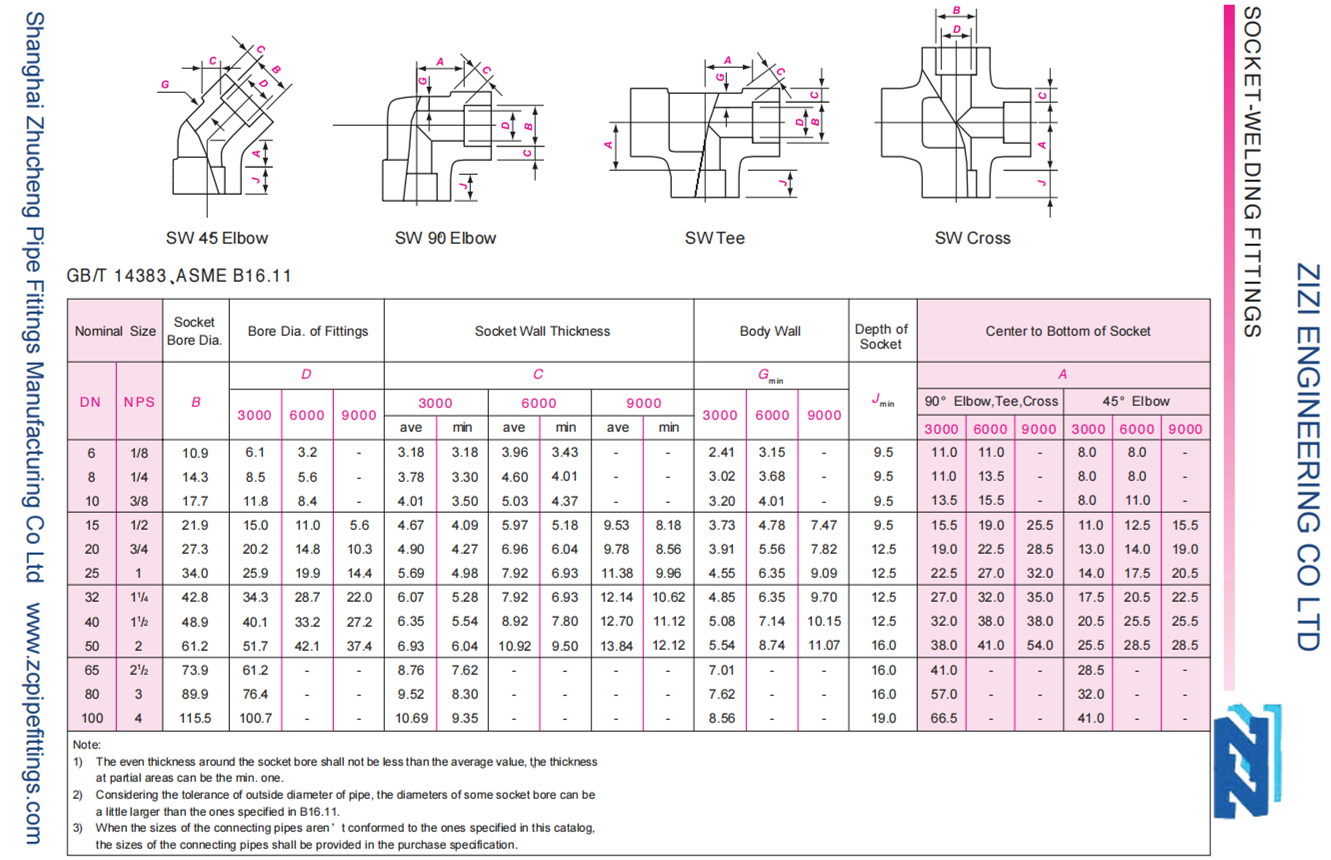

| Shape | Elbow, Tee, Cross, Coupling, Union, Cap, Reducing Insert, Sockolet |

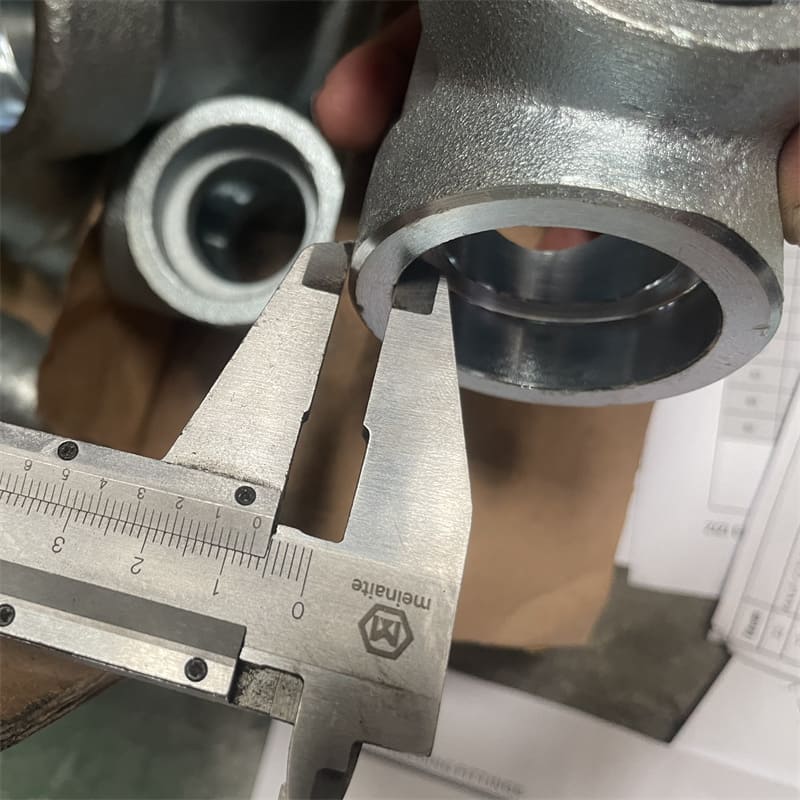

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

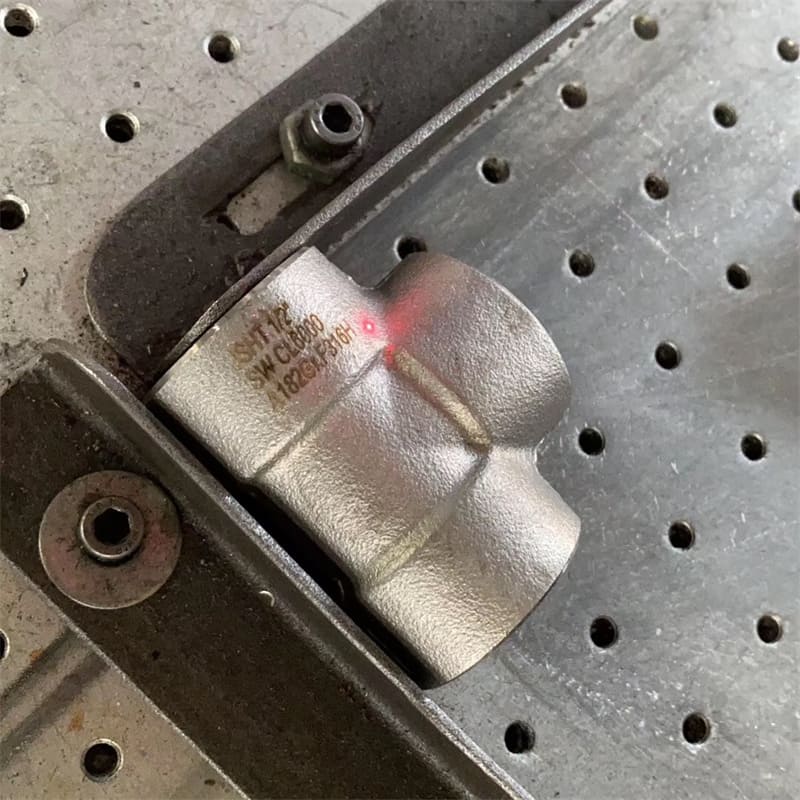

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Product description

45 Degree Socket Weld Elbow is utilized to Put through two pipes with the same ostensible breadth to form the pipe turn 45 degrees.

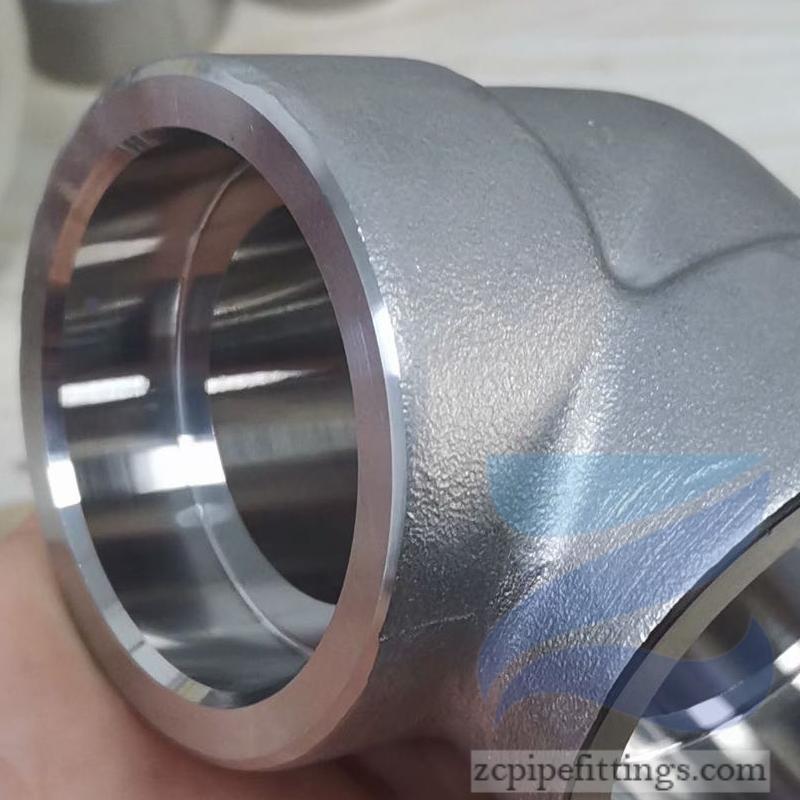

SW 90 Deg ELBOW

Socket Weld 90 Degree Elbow makes 90°changes of course within the run of pipe to create a channeling framework.

Product features

- The socket weld elbow is resistance corrosion/pitting/oxidation/stress corrosion cracking and crevice corrosion.

- It is having high tensile strength and good dimensional accuracy to own

- It withstands heavy loads and also withstands in the high-temperature atmosphere.

- Socket weld Elbow forged fitting has varieties of features such as reliability, durability and dimensional precision.Applications

- petrochemical industry

- medical science

- power

- space flight

- military project