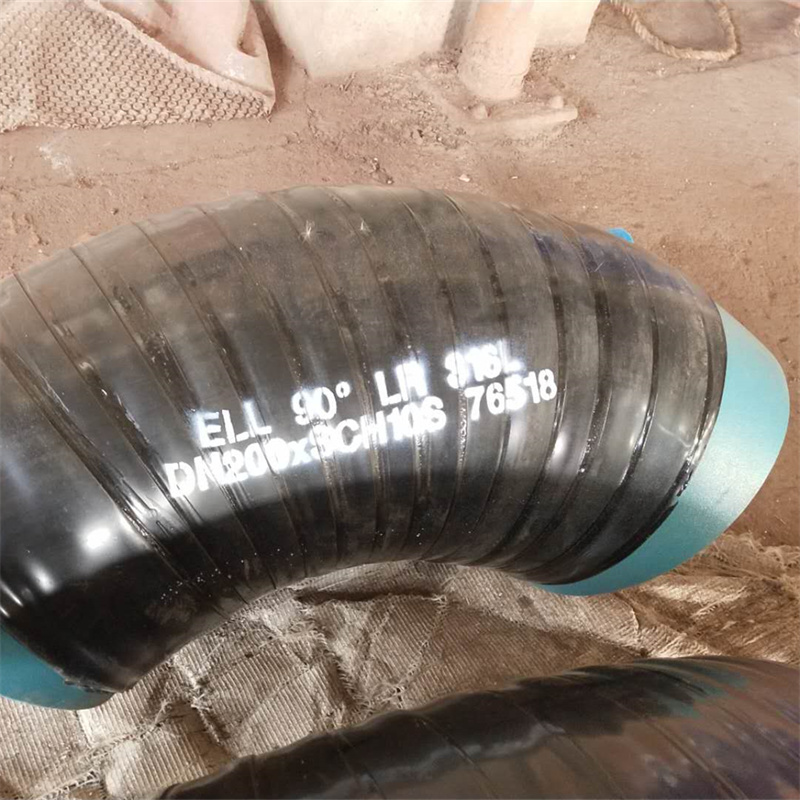

S31254 Elbow is a pipe fitting used in pipeline systems, and its main function is to change the flow direction of the fluid in the pipeline. Common bending angles are 45°, 90° and 180°, etc. It also plays the role of connecting different pipeline sections. In industrial pipeline networks, such as pipeline systems in the petrochemical industry, S31254 elbows connect pipelines in different directions to ensure the continuity of the pipeline system. Moreover, due to the good welding performance of S31254 material, the elbow can be easily welded with other S31254 pipes or pipe fittings to ensure the sealing and stability of the entire pipeline system.

Due to its excellent corrosion resistance, S31254 elbows are widely used in chemical, marine engineering, papermaking, food processing and other industries. In the chemical industry, it is used to transport various corrosive chemical media, such as strong acid and strong alkali solutions. In marine engineering, it can be used for seawater desalination equipment, pipeline systems of offshore oil platforms, etc.

Specification of A403 UNS S31254 Butt Weld Pipe Fittings

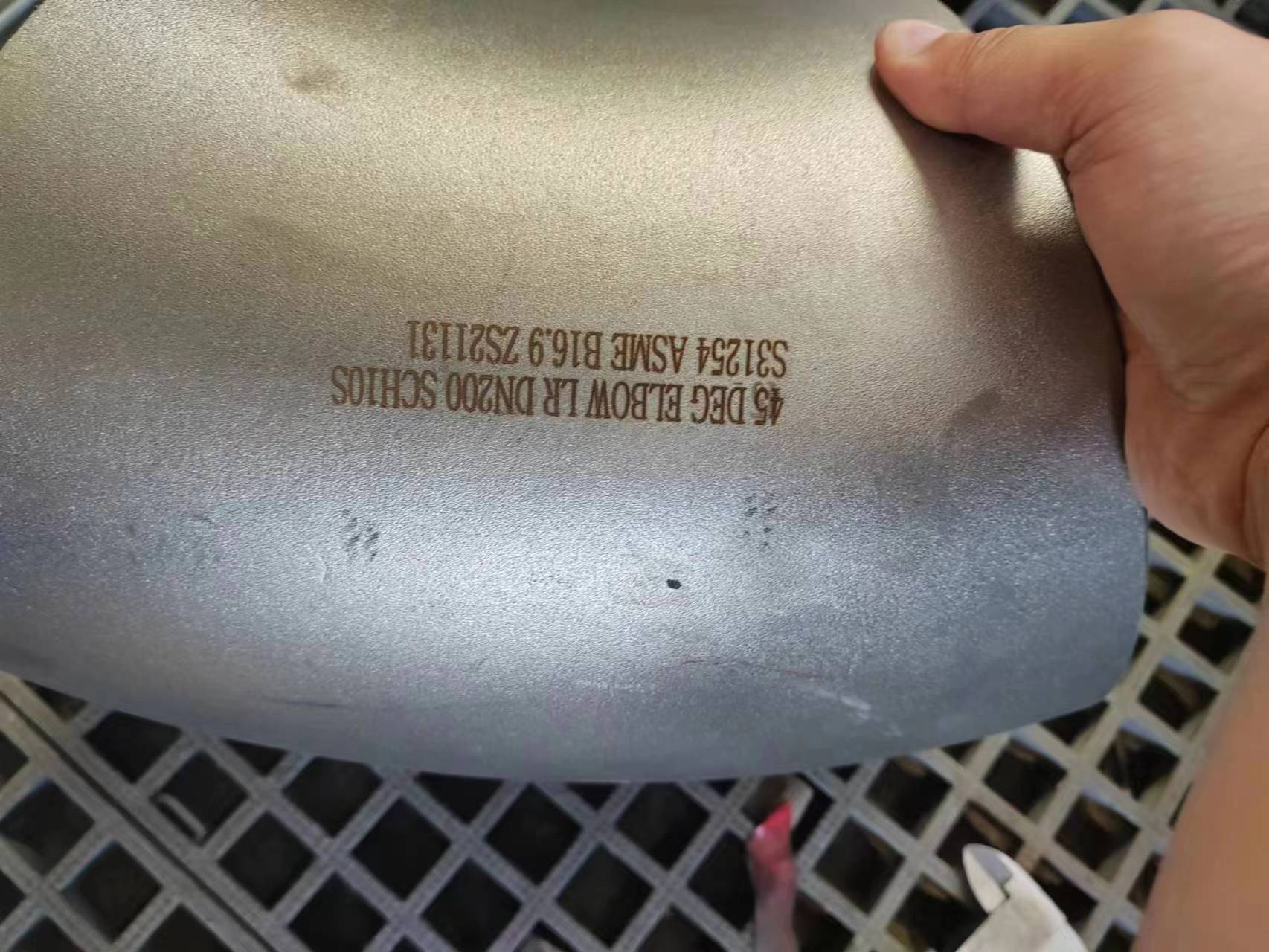

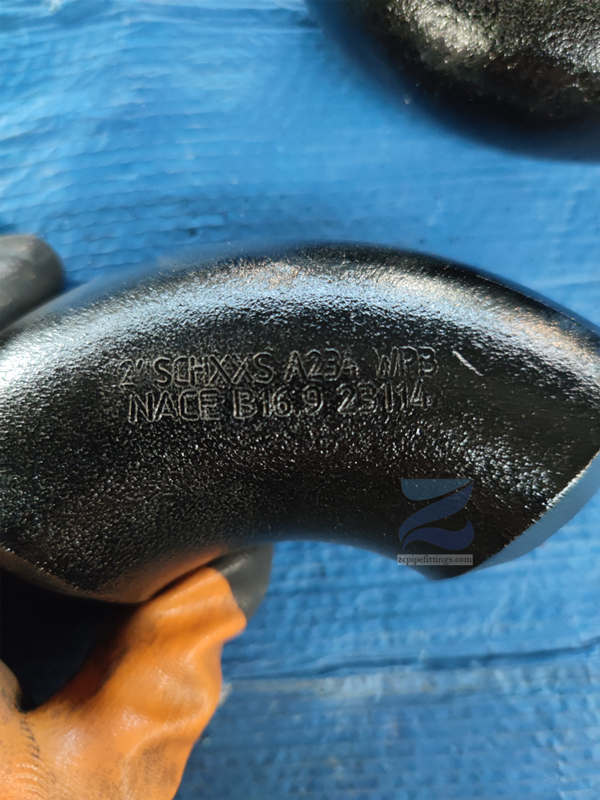

| Specifications | ASTM A403 / ASME SA403 |

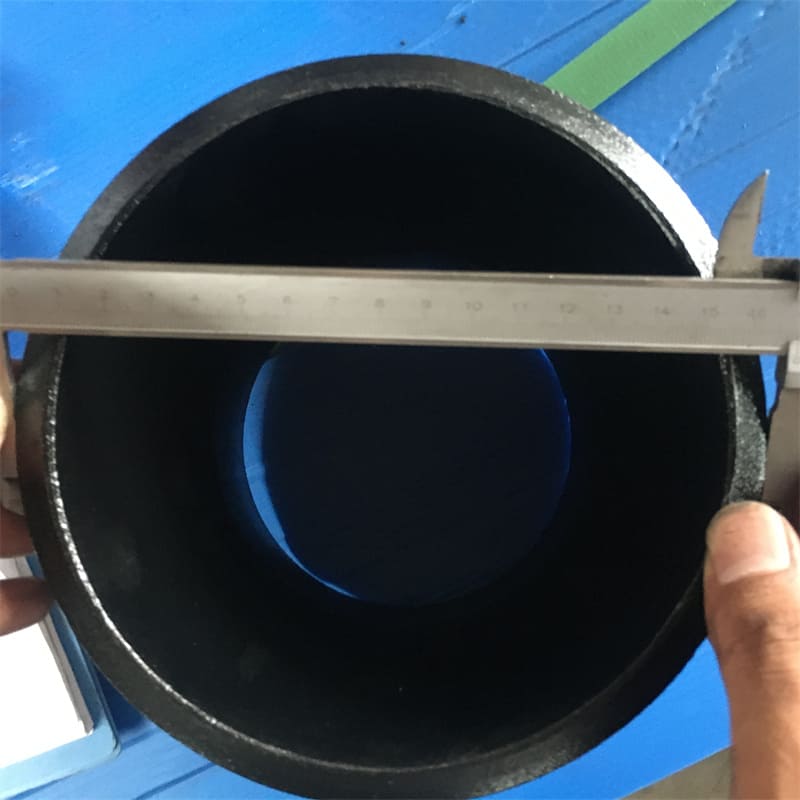

| Size | Seamless Butt Weld Fittings : 1/2″ – 10″ Welded Butt Weld Fittings : 1/2″ – 48″ |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

Material of SMO 254

SMO 254 pipe fittings are resistant to bromides, fluorides and chlorides. They have high ductility and high strength. The minimum tensile strength is 650MPa and the minimum yield strength is 300MPa.

Chemical Composition of SMO 254 Pipe Fittings

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | Cu |

| SMO 254(UNS S31254) | MIN | 17.50 | 19.50 | 6.00 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| SMO 254(UNS S31254) | 650 min | 300 min | 35 min | 50 min |

Equivalent Grades A403 UNS S31254 Butt weld Fittings

| STANDARD | AFNOR | WERKSTOFF NR. | UNS | SIS | EN |

| SMO 254 | Z1 CNDU 20.18.06Az | 1.4547 | S31254 | 2378 | X1CrNiMoCuN20-18-7 |

Application of S31254 45° Elbow

Excellent corrosion resistance

S31254 elbow is made of super austenitic stainless steel, which contains high content of alloy elements such as chromium (Cr), nickel (Ni), molybdenum (Mo) and nitrogen (N). Chromium can form a stable passivation film, which effectively resists oxidation corrosion. Nickel enhances the stability of the material in various corrosive environments. Molybdenum makes the elbow have excellent corrosion resistance to chloride ion-containing media,

Good mechanical properties

S31254 material itself has high strength. In the pipeline system, the elbow, as a component that changes the flow direction, needs to withstand the pressure of the medium in the pipeline. S31254 elbow can withstand high internal pressure, whether in high-pressure hydraulic systems or in some industrial pipelines that need to transport media over long distances, it can ensure the integrity of the pipeline. It also has good toughness, which means that S31254 elbow is not prone to brittle fracture when subjected to certain external impacts or vibrations of the pipeline system.

High temperature resistance

S31254 elbow can work normally in a high temperature environment. In some high-temperature industrial processes, such as the high-temperature distillation unit of an oil refinery or the steam transmission pipeline system of a power plant, the medium temperature in the pipeline may reach several hundred degrees. At such high temperatures, the material properties of the S31254 elbow will not drop sharply, and the structure can be kept stable to ensure the safe operation of the pipeline system.

High-precision manufacturing process

Whether the S31254 elbow is manufactured by hot bending or cold bending, a high dimensional accuracy can be achieved. In the pipeline system, the accuracy of the dimensions of the elbow, such as the nominal diameter, bending angle and bending radius, is very important. Accurate dimensions can ensure good connection between the elbow and other pipe fittings or equipment and reduce the resistance of the fluid in the pipeline system.