Home » Buttwelding Fittings » 90° LR Carbon Steel Butt Weld Elbow

Previous:

ASTM A234WPB 90 Degree Elbow 6IN SCH40

Content

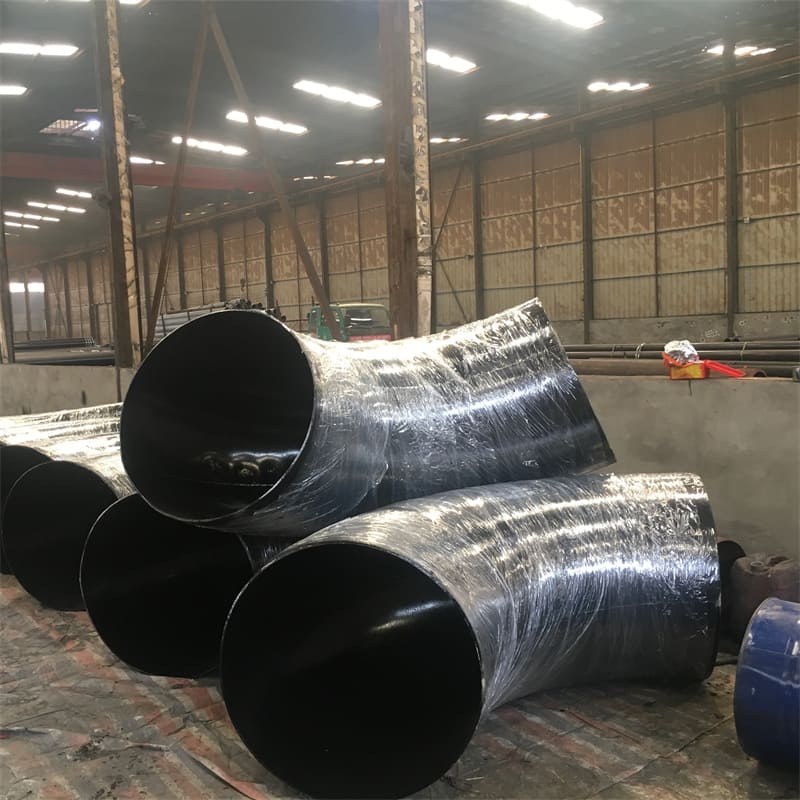

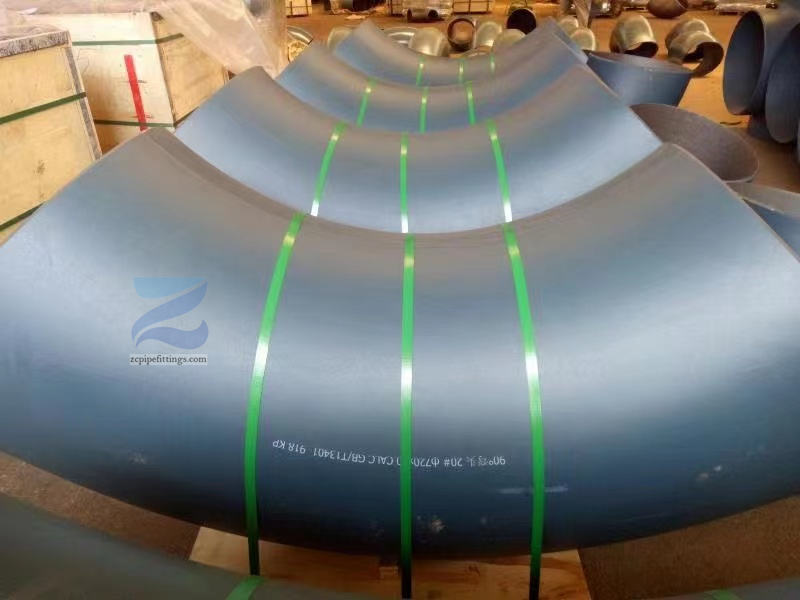

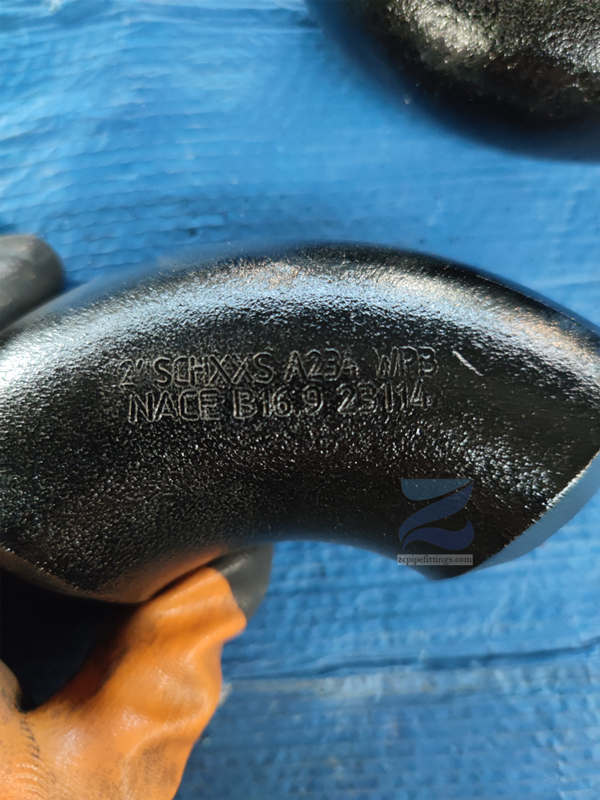

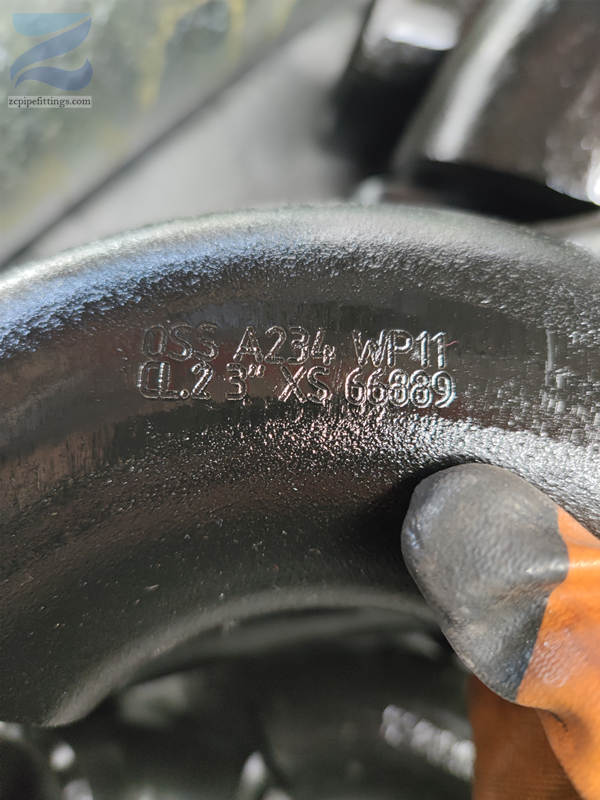

Carbon steel butt welding 90 degree elbow is a connector specially designed for use in piping systems. Its main function is to create a 90 degree turn in the pipe so that the fluid can flow along a predetermined path. This elbow is usually made of carbon steel material. It is suitable for various industrial environments due to its good strength and corrosion resistance. Carbon steel butt welding 90 degree elbow plays a vital role in industrial piping systems, especially in situations where the direction of the fluid needs to be changed, such as in industries such as petrochemicals, power and construction.

Specification of ASME B16.9 90 Degree Elbow

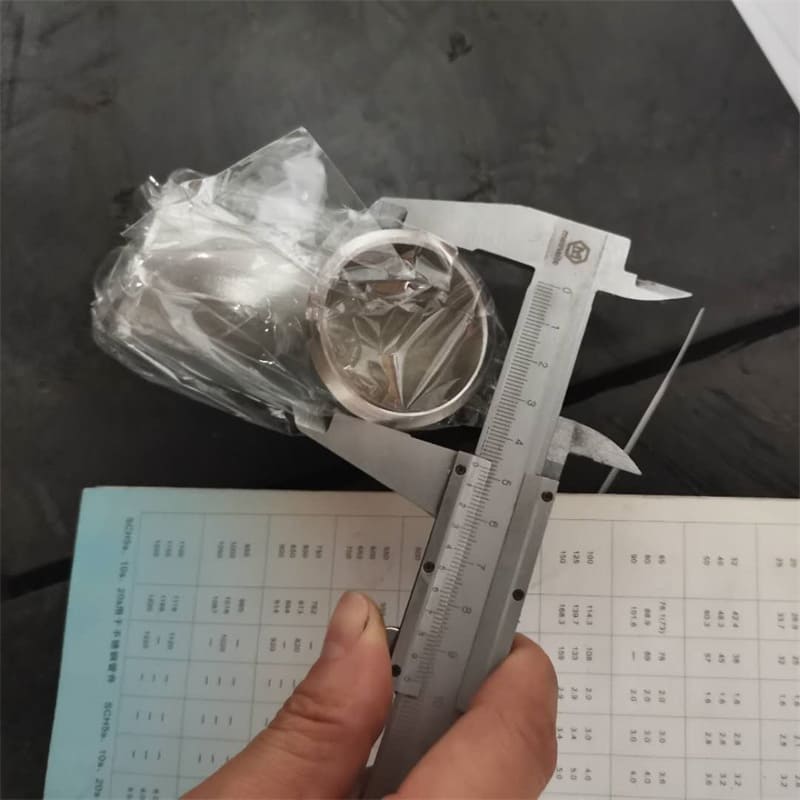

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

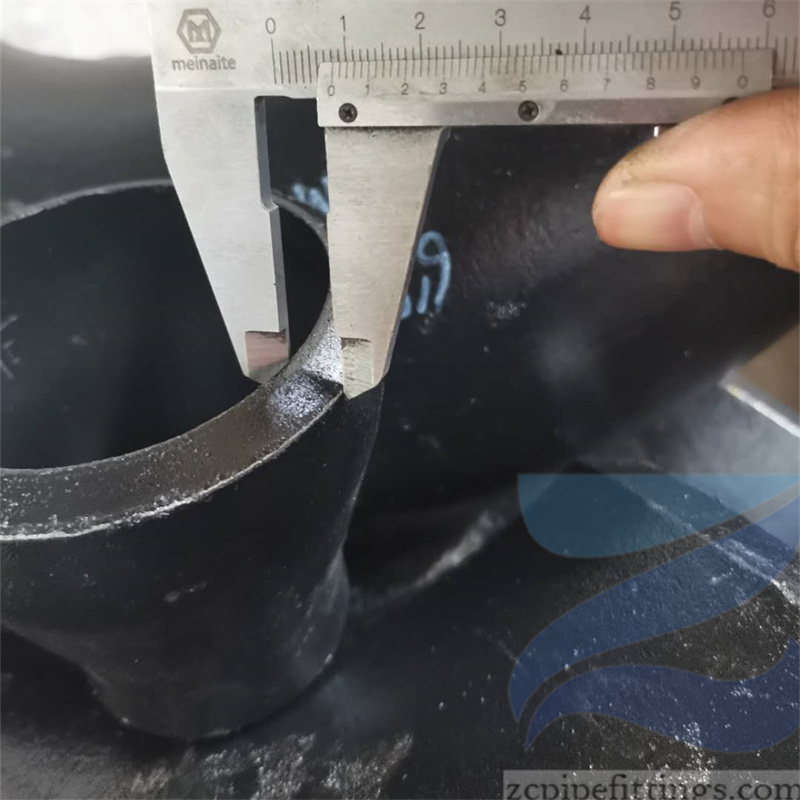

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Carbon Steel Grades | ASTM A234 WPB/WPC, A420 WPL6, A860 WPHY 42 / 46 / 56 / 60 / 65 |

ASME B16.9 90 Degree Long Radius Elbow Weight Chart

| DN | NPS | Sch10 | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS |

| 15 | 1/2 | 0.06 | – | 0.07 | 0.08 | 0.08 | – | 0.11 | 0.11 | – | – | 0.13 | 0.17 |

| 20 | 3/4 | 0.08 | – | 0.09 | 0.11 | 0.11 | – | 0.14 | 0.14 | – | – | 0.19 | 0.24 |

| 25 | 1 | 0.13 | – | 0.14 | 0.16 | 0.16 | – | 1.12 | 1.12 | – | – | 0.28 | 0.36 |

| 32 | 1 1/4 | 0.21 | – | 0.24 | 0.28 | 0.28 | – | 0.24 | 0.24 | – | – | 0.47 | 0.64 |

| 40 | 1 1/2 | 0.28 | – | 0.35 | 0.4 | 0.4 | – | 0.53 | 0.53 | – | – | 0.71 | 0.94 |

| 50 | 2 | 0.47 | – | 0.59 | 0.71 | 0.71 | – | 0.98 | 0.98 | – | – | 1.46 | 1.76 |

| 65 | 2 1/2 | 0.79 | – | 1.32 | 1.42 | 1.42 | – | 1.87 | 1.87 | – | – | 2.45 | 3.35 |

| 80 | 3 | 1.16 | – | 1.95 | 2.22 | 2.22 | – | 3.01 | 3.01 | – | – | 4.2 | 5.45 |

| 90 | 3 1/2 | 1.55 | – | 2.62 | 3.12 | 3.12 | – | 4.28 | 4.28 | – | – | – | – |

| 100 | 4 | 2.02 | – | 3.39 | 4.22 | 4.22 | – | 5.86 | 5.86 | – | 7.44 | 8.81 | 10.8 |

| 125 | 5 | 3.46 | – | – | 7.15 | 7.15 | – | 10.2 | 10.2 | – | 13.2 | 16.1 | 18.9 |

| 150 | 6 | 4.98 | – | – | 11.2 | 11.2 | – | 16.8 | 16.8 | – | 21.4 | 26.7 | 31.3 |

| 200 | 8 | 9.57 | 17.6 | 19.4 | 22.4 | 22.4 | 28 | 34.1 | 34.1 | 40 | 47.7 | 58.6 | 56.9 |

| 250 | 10 | 16.7 | 27.5 | 33.6 | 39.7 | 39.7 | 53.7 | 53.7 | 63.2 | 75.5 | 87.6 | 113 | 102 |

| 300 | 12 | 25.9 | 39.3 | 51.5 | 58.3 | 62.9 | 86 | 76.9 | 104 | 126 | 148 | 188 | 148 |

| 350 | 14 | 34.7 | 62.5 | 74.9 | 74.9 | 87.1 | 117 | 98.9 | 146 | 180 | 207 | 259 | – |

| 400 | 16 | 45.4 | 82 | 98.3 | 98.3 | 130 | 169 | 130 | 215 | 259 | 302 | 385 | – |

| 450 | 18 | 56.2 | 104 | 145 | 125 | 185 | 244 | 165 | 302 | 367 | 431 | 545 | – |

| 500 | 20 | 82.2 | 154 | 204 | 154 | 242 | 326 | 204 | 410 | 502 | 581 | 744 | – |

| 550 | 22 | 143 | 187 | 248 | 187 | – | 426 | 248 | 541 | 654 | 763 | 974 | – |

| 600 | 24 | 170 | 223 | 331 | 223 | 403 | 561 | 295 | 698 | 865 | 1011 | 1277 | – |

| 650 | 26 | 200 | 347 | – | 262 | – | – | 347 | – | – | – | – | – |

| 700 | 28 | 232 | 403 | 478 | 304 | – | – | 403 | – | – | – | – | – |

| 750 | 30 | 267 | 464 | 577 | 349 | – | – | 464 | – | – | – | – | – |

| 800 | 32 | 304 | 528 | 658 | 398 | 722 | – | 528 | – | – | – | – | – |

| 850 | 34 | 343 | 597 | 743 | 449 | 817 | – | 57 | – | – | – | – | – |

| 900 | 36 | 386 | 669 | 834 | 504 | 997 | – | 669 | – | – | – | – | – |

| 950 | 38 | – | – | – | 562 | – | – | 746 | – | – | – | – | – |

| 1000 | 40 | – | – | – | 623 | – | – | 828 | – | – | – | – | – |

| 1050 | 42 | – | – | – | 687 | – | – | 913 | – | – | – | – | – |

| 1100 | 44 | – | – | – | 754 | – | – | 1003 | – | – | – | – | – |

| 1150 | 46 | – | – | – | 825 | – | – | 1096 | – | – | – | – | – |

| 1200 | 48 | – | – | – | 898 | – | – | 1194 | – | – | – | – | – |

| 1300 | 52 | – | – | – | 1107 | – | – | – | – | – | – | – | – |

| 1400 | 56 | – | – | – | 1284 | – | – | – | – | – | – | – | – |

| 1500 | 60 | – | – | – | 1475 | – | – | – | – | – | – | – | – |

| 1600 | 64 | – | – | – | 1679 | – | – | – | – | – | – | – | – |

| 1700 | 68 | – | – | – | 1869 | – | – | – | – | – | – | – | – |

| 1800 | 72 | – | – | – | 2126 | – | – | – | – | – | – | – | – |

| 1900 | 76 | – | – | – | 2372 | – | – | – | – | – | – | – | – |

| 2000 | 80 | – | – | – | 2626 | – | – | – | – | – | – | – | – |

Application range of carbon steel butt welding elbow

The application fields of carbon steel butt-welded 90-degree elbows are very wide, mainly concentrated in the following industries:

- Petrochemical industry: Because it needs to handle a large amount of chemicals and high temperature and high pressure environment, carbon steel butt-welded elbows can provide reliable pipeline connection and direction change to ensure the safety and efficiency of fluid transportation.

- Power industry: Cooling water systems, steam pipelines, etc. in power facilities all need to use carbon steel butt-welded elbows to optimize pipeline layout and reduce energy loss.

- Construction industry: This is an important application field of carbon steel butt-welded elbows, especially in the water supply system and fire protection system of high-rise buildings. This elbow can effectively change the direction of the pipeline and adapt to complex building structures.

Inquiry

More Buttwelding Fittings