ASME B16.11 Socket Weld Pipe Fittings

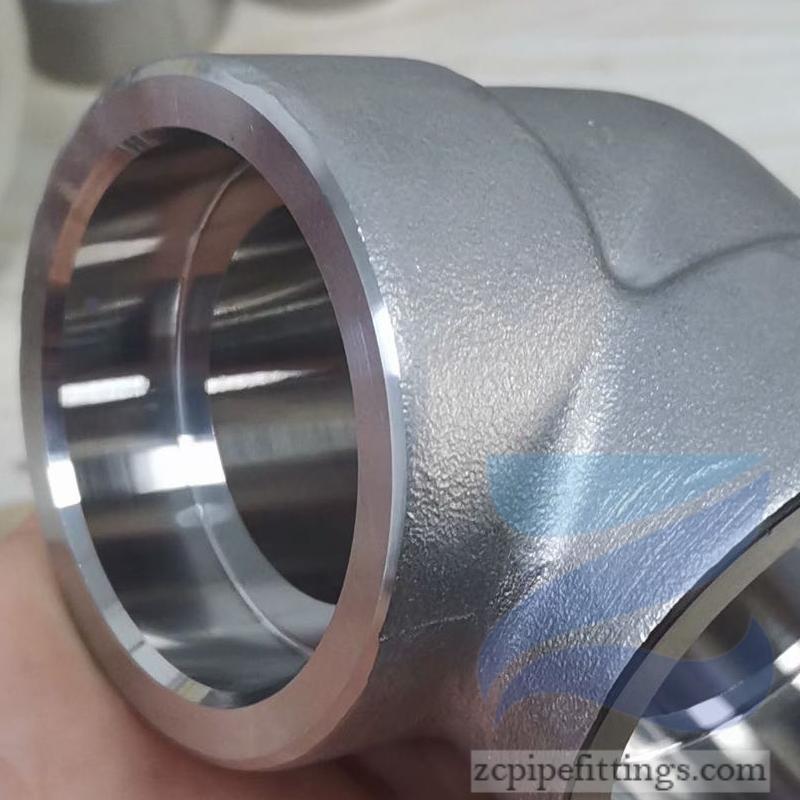

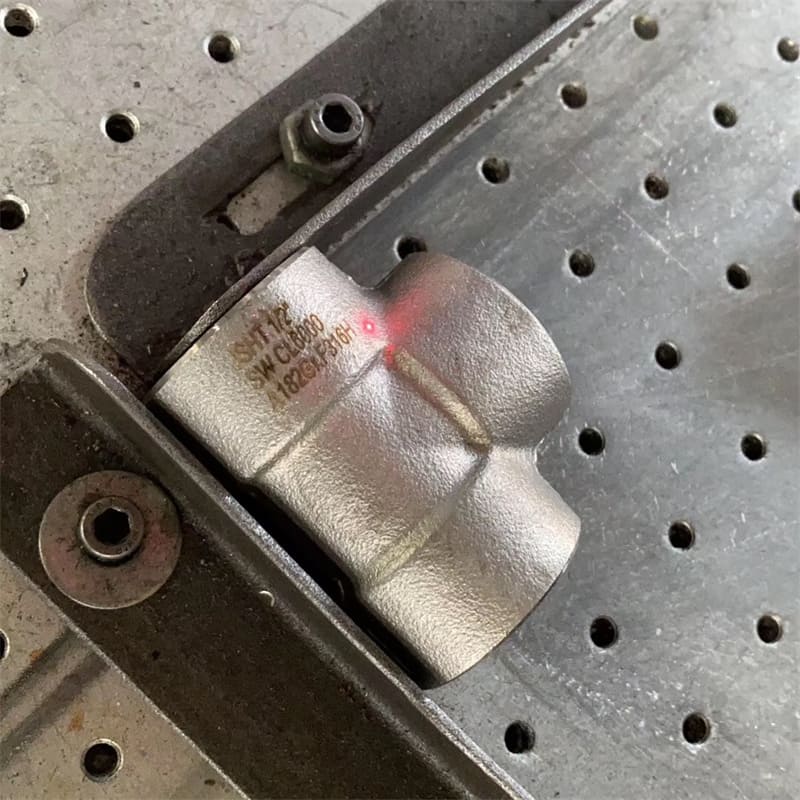

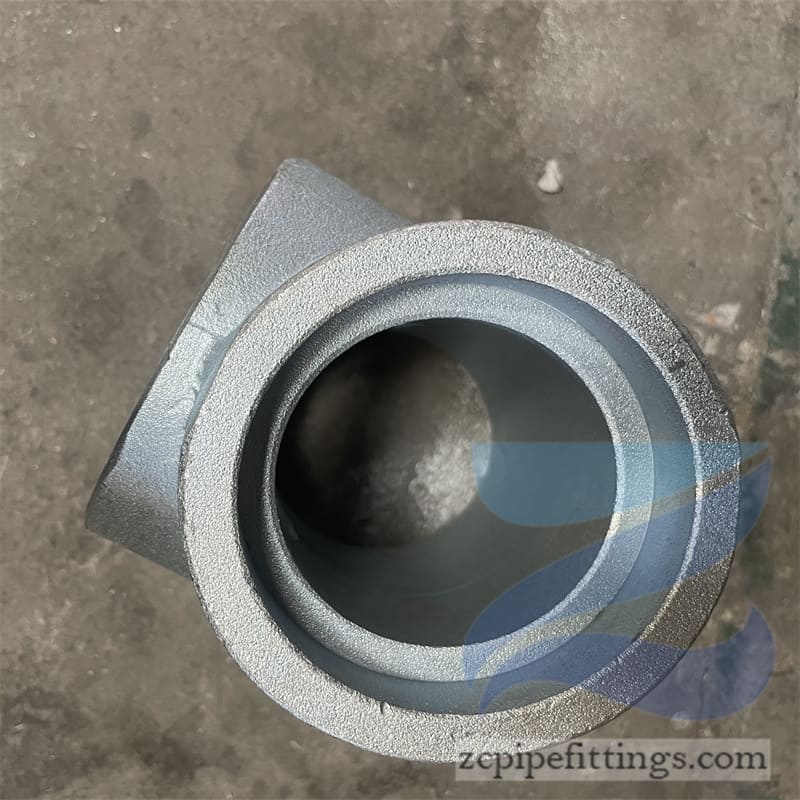

Socket weld pipe fittings are pipe connectors made of round steel or steel ingots after forging and then lathe machining. The main connection form is socket welding (SW), which is to insert the steel pipe into the socket hole for welding.

Socket weld pipe fittings are pipe connectors made of round steel or steel ingots after forging and then lathe machining. The main connection form is socket welding (SW), which is to insert the steel pipe into the socket hole for welding.

There are many varieties of socket fittings, including but not limited to 45° elbows, 90° elbows, tees, crosses, full coupling, half coupling, caps, unions, outlets, etc. The raw materials for making these pipe fittings are generally carbon steel, stainless steel, alloy steel, etc. Pipe fittings of different materials are suitable for different working environments and pressure levels.

Socket weld pipe fittings are widely used in various industries, such as petroleum, chemical, pharmaceutical, water treatment and other industrial fields, as well as pipe connections in buildings and other structures.

ASME B16.11 Socket Weld Pipe Fittings Specification

A H

A H